My Garage

My Account

Cart

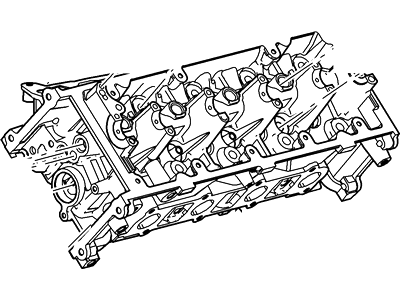

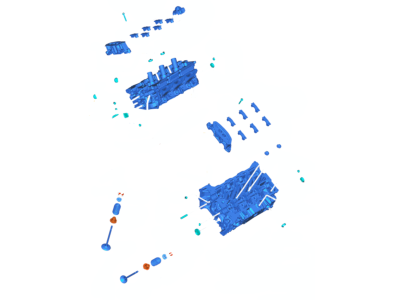

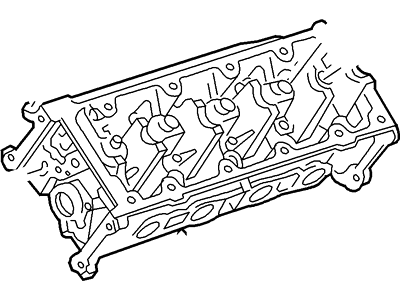

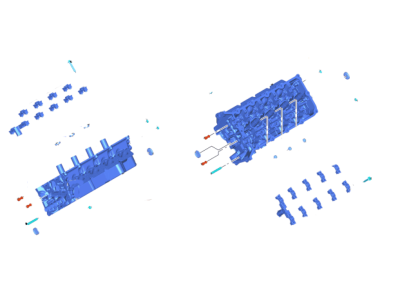

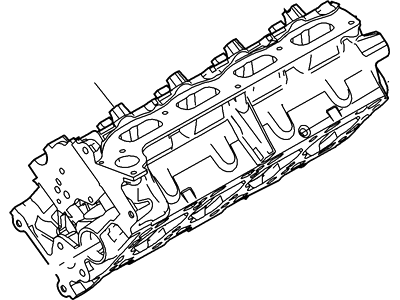

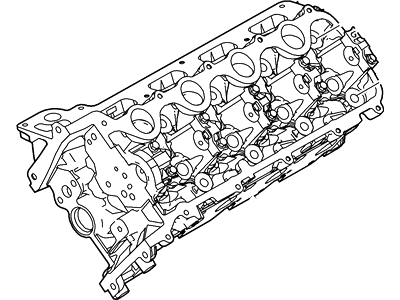

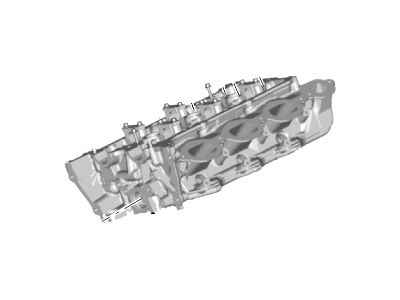

Genuine Ford F-150 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

112 Cylinder Heads found

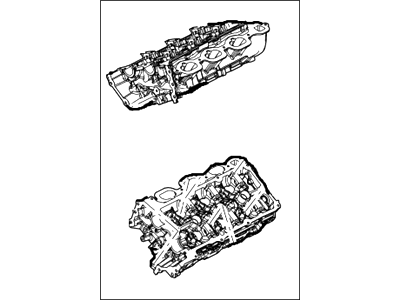

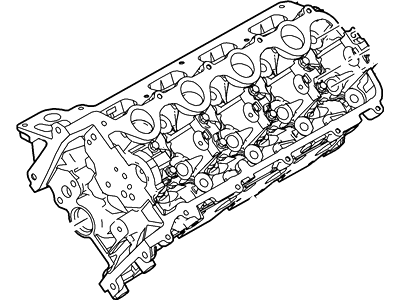

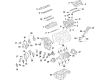

Ford F-150 Cylinder Head Assembly

Part Number: 6W7Z-6049-A$589.49 MSRP: $824.62You Save: $235.13 (29%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: FL3Z-6049-J$3308.91 MSRP: $4863.69You Save: $1554.78 (32%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: 4L3Z-6049-AA$605.57 MSRP: $824.62You Save: $219.05 (27%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: JL3Z-6049-D$949.93 MSRP: $1390.77You Save: $440.84 (32%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: FL3Z-6049-K$3516.45 MSRP: $4823.08You Save: $1306.63 (28%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: DG1Z-6049-C$892.29 MSRP: $1218.46You Save: $326.17 (27%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: JL3Z-6049-N$1375.91 MSRP: $1980.00You Save: $604.09 (31%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: HL3Z-6049-J$1750.21 MSRP: $2396.92You Save: $646.71 (27%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: JL3Z-6049-M$949.93 MSRP: $1390.77You Save: $440.84 (32%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: EK4Z-6049-D$673.11 MSRP: $983.23You Save: $310.12 (32%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: 9L3Z-6049-GB$275.03 MSRP: $371.67You Save: $96.64 (26%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: 9L3Z-6049-E$2890.50 MSRP: $4247.69You Save: $1357.19 (32%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: EK4Z-6049-C$673.11 MSRP: $983.23You Save: $310.12 (32%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: DL3Z-6049-A$1141.61 MSRP: $1641.54You Save: $499.93 (31%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: FL3Z-6049-D$3308.91 MSRP: $4863.69You Save: $1554.78 (32%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: JL3Z-6049-B$851.28 MSRP: $1245.54You Save: $394.26 (32%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: AT4Z-6049-D$892.29 MSRP: $1218.46You Save: $326.17 (27%)Ships in 1-3 Business DaysFord F-150 Cylinder Head Assembly

Part Number: 8L3Z-6049-B$275.03 MSRP: $371.67You Save: $96.64 (26%)Ships in 1-2 Business DaysFord F-150 Cylinder Head Assembly

Part Number: JT4Z-6049-C$941.57 MSRP: $1286.15You Save: $344.58 (27%)

| Page 1 of 6 |Next >

1-20 of 112 Results

Ford F-150 Cylinder Head

We provide a wide range of Ford F-150 Cylinder Head at the best prices possible. If you need Ford F-150 Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford F-150 Cylinder Head Parts Questions & Experts Answers

- Q: What precautions should be taken when working and How to remove and install the cylinder heads in V8 engine on Ford F-150?A:Engines are unforgiving as many procedures need at least some special tools, this is more pronounced in the Timing Chains where one has to be very careful not to damage the engine. Cylinder heads should be removed when the engine is cold to avoid warpage but one can take advantage of this by ensuring that the engine is sufficiently cool in this respect. To start the procedure you must purge fuel system pressure, remove the negative terminal of battery, and drain the cooling system. Depend the valve covers, Intake Manifold and the Exhaust Manifold and then proceed to pull out the timing chains, tensioners, sprockets and the Camshafts. With the aid of a breaker bar, unscrew the cylinder head bolts in the correct procedure, lifting the cylinder head(s) from the engine and, if there is a problem, use wood and a hammer. Tin the aluminum cylinder head gasket sealing surfaces before installing the heads, and to remove a stuck head, you pry at the corners using a pry bar and this will not damage the sealing surface. The cylinder head gaskets should be pulled off the engines and the original positions should be taken into consideration as the gaskets are not to be interchanged. On reassembly, new cylinder head bolts have to be used to avoid leaks and damage, that are likely to occur in future. Make sure the mating surfaces of the cylinder heads and engine block are clean, and use only a gasket scraper or silicone gasket remover; do not use anything abrasive that could cause future leakages. Look for crack or any other defects on the mating surfaces and bottoms of the bolt holes; run a tap along the threads of bolt holes. Fit the new gaskets in place over the alignment dowels, fit the cylinder heads without disturbing the gaskets, and fit a new cylinder head bolts and tighten in a stage manner starting with the torque-angle technique. Last but not the least, reverse, do the final tightening, change the engine oil and filter, and fill the cooling system and start the engine and check for the leaks.

Related Ford F-150 Parts

Browse by Year

2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head