My Garage

My Account

Cart

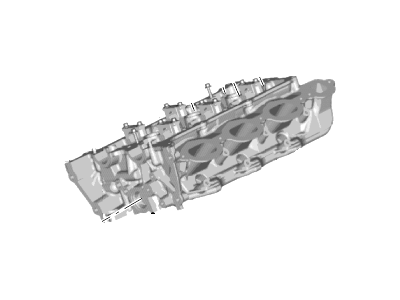

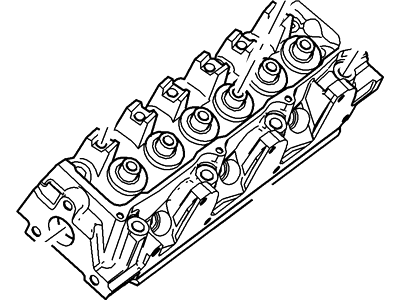

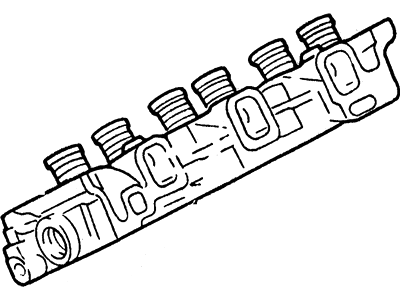

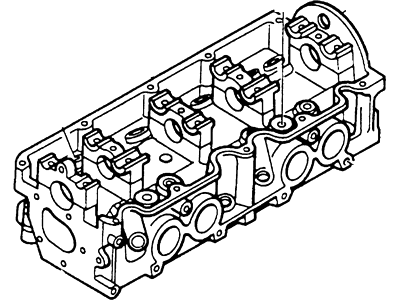

Genuine Ford Taurus Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Cylinder Heads found

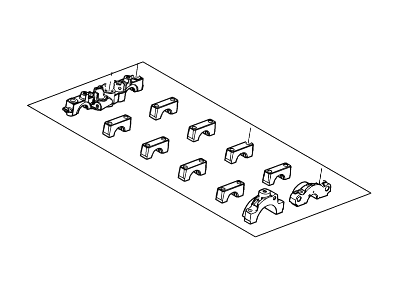

Ford Taurus Cylinder Head Assembly

Part Number: CJ5Z-6049-B$783.65 MSRP: $1069.23You Save: $285.58 (27%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: DG1Z-6049-C$892.29 MSRP: $1218.46You Save: $326.17 (27%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: YL8Z-6049-AA$735.38 MSRP: $1078.00You Save: $342.62 (32%)Ships in 1-2 Business DaysFord Taurus Cylinder Head Assembly

Part Number: AT4Z-6049-D$892.29 MSRP: $1218.46You Save: $326.17 (27%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: F6DZ-6049-BA$789.32 MSRP: $1092.12You Save: $302.80 (28%)Ships in 1-2 Business DaysFord Taurus Cylinder Head Assembly

Part Number: F4DZ6049C$529.85 MSRP: $725.63You Save: $195.78 (27%)Ships in 1-2 Business DaysFord Taurus Cylinder Head Assembly

Part Number: DG1Z-6049-A$589.46 MSRP: $795.38You Save: $205.92 (26%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: AA5Z-6049-E$827.33 MSRP: $1129.23You Save: $301.90 (27%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: AT4Z-6049-C$589.46 MSRP: $795.38You Save: $205.92 (26%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: YF1Z-6049-GA$769.45 MSRP: $1052.62You Save: $283.17 (27%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: 7T4Z-6049-A$3780.77 MSRP: $5186.15You Save: $1405.38 (28%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: 9T4Z-6049-B$3780.77 MSRP: $5186.15You Save: $1405.38 (28%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: AA5Z-6049-D$2061.57 MSRP: $2824.62You Save: $763.05 (28%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: 7T4Z-6049-B$592.91 MSRP: $807.23You Save: $214.32 (27%)Ships in 1-3 Business DaysFord Taurus Cylinder Head Assembly

Part Number: 9T4Z-6049-A$592.91 MSRP: $807.23You Save: $214.32 (27%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 33 Results

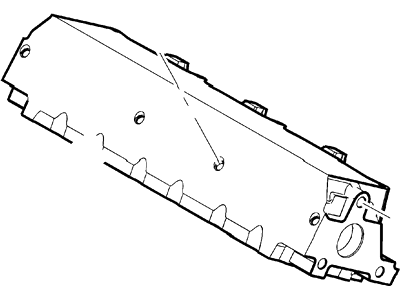

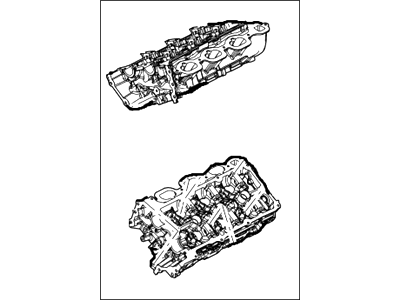

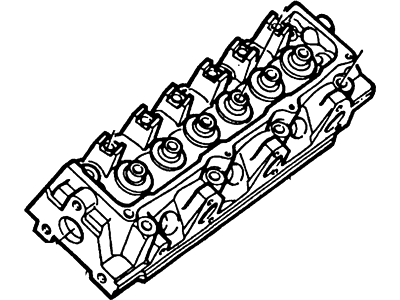

Ford Taurus Cylinder Head

We provide a wide range of Ford Taurus Cylinder Head at the best prices possible. If you need Ford Taurus Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Taurus Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and install cylinder heads in V6 engine on Ford Taurus?A:Release the pressure of the fuel system, then, remove the connection of the negative terminal of the battery. Drain the cooling system. Depower the upper and lower intake manifold. Having selected the car, lift it on a rise and put it on the jackstands, then, turn off the frontal oxygen sensors and the catalytic converters. Disconnect the two Camshaft Position (CMP) sensors mounted at the rear of each cylinder head, and the Cylinder Head Temperature (CHT) sensor, the sensor for the catalytic converter monitor and the other two Camshaft Position (CMP) sensors. To enhance the removal process, it is also necessary to unscrew the camshafts from the cylinder head you want to remove. If necessary, remove bolts or clips used to attach wiring harnesses or ground straps to heads of cylinders. Remove the Exhaust Manifold(s). Any further fixture that could hinder the process of the removal of the cylinder head must also be undone. Take off all the hoses and electrical connectors from the coolant bypass tube, unscrew two bolts which hold this metal tubule. Either apply the above heating to each bolt for about half an hour then slacken each bolt in turn, or heat the cylinder head until it is at the correct temperature then slacken all the bolts a quarter turn at a time as follows: Take out the bolts and dispose them as a new bolt must be used when replacing cylinder head (s). Remove the cylinder head(s) from the engine, being very careful when doing so not to prise between the cylinder head and the engine block. To remove cylinder head knock off the wood block against a touching end of the head or apply a pry against a casting projection using hammer. To remove cylinder heads one need to store it on the blocks of wood so that gasket sealing surfaces would not be damaged. Cylinder head disassembly and inspection procedures must be done professionally and this should be done by an automotive machine shop. The surfaces where the cylinder heads are to be placed should be very clean when placing the cylinder heads and all other openings should be covered with several layers of shop rags to avoid accidental introduction of debris in the engine. Sweep the floor and clear the valley or intake ports if the centres will require a vacuum cleaner. Broken gasket surfaces must NOT be scraped or machined with a scraper or abrasives discs, as the block, heads, and intake manifold are made of aluminum. It is necessary to carefully inspect engine block and the surface of the cylinder head: shaving, deep scratches or other damages are often possible to remove with a file, but serious damage will require and additional engine block machining. Check the block for warpage, by placing a straightedge on the block and using a feeler gauge, if the block is warped, it is recommended that the head should be taken for machining. To chase the threads in the block head bolt holes use a tap of the right size because the bolt holes are often full of dirt, corrosion, sealant and even damaged threads. Place the new gasket(s) in the over the dowel pins located in the engine block with the correct orientation. If the cylinder head is to be replaced then a new secondary timing chain tensioner will be needed. Gently place the cylinder head(s) on the engine block putting the gasket in its right position without being disturbed. New cylinder head bolts should be lightly oiled and then run down until only slightly tight. Cylinder head bolts are of torque-to-yield type and must be thrown away and new ones installed at the time of assembling. Are: Turn the bolts in the sequence with a torque wrench and a breaker bar having your torque angle adapter to get to the correct angle of rotation tighten the bolts as follows to the required torque and angle of rotation. The rest part of the installation process is the process of dismantling with an addition of tightening of fasteners to the corresponding torque value. Replace the engine oil and the filter, then refuel and purge the cooling system. Switch on the engine to be used and look out for any signs of leakage.

Related Ford Taurus Parts

Browse by Year

2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head