My Garage

My Account

Cart

Genuine Ford Focus Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Oil Pans found

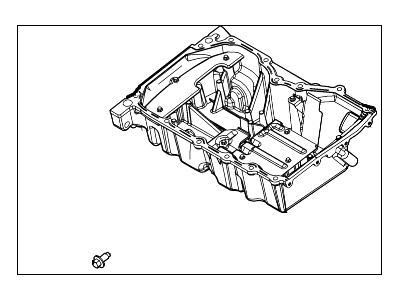

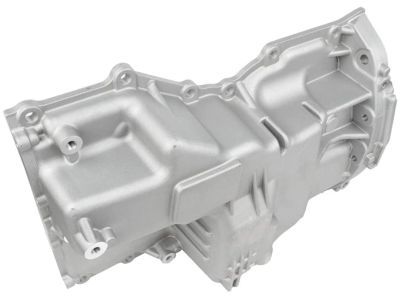

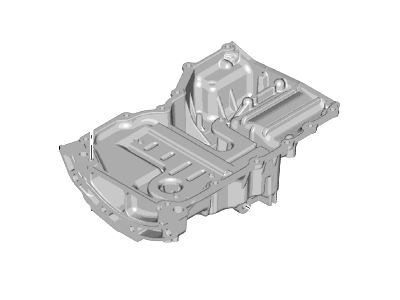

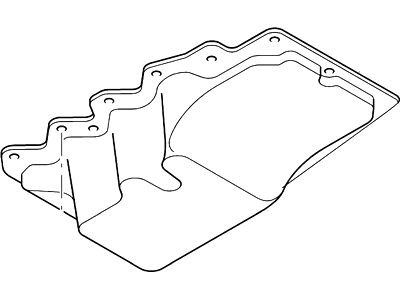

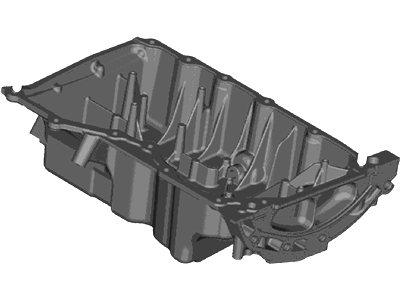

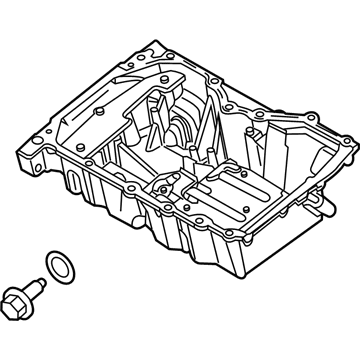

Ford Focus Engine Oil Pan Assembly

Part Number: CJ5Z-6675-D$160.09 MSRP: $248.20You Save: $88.11 (36%)Ford Focus Engine Oil Pan Assembly

Part Number: CP9Z-6675-A$117.04 MSRP: $180.95You Save: $63.91 (36%)Ships in 1 Business DayFord Focus Engine Oil Pan Assembly

Part Number: YS4Z-6675-AA$95.55 MSRP: $139.70You Save: $44.15 (32%)Ford Focus Engine Oil Pan Assembly

Part Number: CJ5Z-6675-A$160.09 MSRP: $248.20You Save: $88.11 (36%)Ships in 1-2 Business DaysFord Focus Engine Oil Pan Assembly

Part Number: 3M4Z-6675-AA$123.14 MSRP: $180.03You Save: $56.89 (32%)Ships in 1-3 Business DaysFord Focus Engine Oil Pan Assembly

Part Number: G1FZ-6675-A$228.26 MSRP: $336.67You Save: $108.41 (33%)Ford Focus Engine Oil Pan Assembly

Part Number: 1S7Z-6675-AA$105.12 MSRP: $153.68You Save: $48.56 (32%)Ships in 1-3 Business Days

Ford Focus Oil Pan

The body of the Ford Focus is an Oil Pan which is responsible for holding engine oil in order to sufficiently lubricate and cool various parts that constitute the engine of the car. Ford Focus for instance mostly uses the wet sump system whereby oil is stored in the Oil Pan below the engines. The oil pump with the help of a pickup tube sucks the oil, circulates it through the engine and then oil comes back to the Oil Pan in order to provide proper lubrication under different operating conditions. In the past, the Ford Focus Oil Pan is produced from stamped steel however, recent development allowed utilization of cast aluminum in several Ford Focus oil pan models to increase sturdiness and reliability. Even if the tasks of a car's Oil Pan stay the same regardless of Ford Focus generation, the changes in the design and materials used intentionally represent improvements of engine technologies to offer the optimal performance and dependability in the functionality of the Oil Pan.

We provide a wide range of Ford Focus Oil Pan at the best prices possible. If you need Ford Focus Oil Pan, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Focus Oil Pan Parts Questions & Experts Answers

- Q: How to remove and install an oil pan in 2.0L SPI engine on Ford Focus?A:Disconnect the negative cable from the battery and securely block the rear wheels to prevent the vehicle from rolling, then jack up the front and place it on jackstands, ensuring not to get under a vehicle supported only by a jack. Drain the engine oil and remove the catalytic converter, noting that the bracket supporting the rear end of the converter outlet pipe bolts to the oil pan, which should also be removed. Take out the bolts securing the axleshaft bracket to the engine and the bolt for the coolant tube, then unbolt the oil pan from the engine and lower it carefully, using a rubber mallet if necessary, while avoiding prying between the pan and engine block to prevent damage. Remove the gasket from the oil pan and unbolt the oil strainer from the Oil Pump if needed. Clean all traces of the old gasket from the mating surfaces of the oil pan and engine block with a plastic scraper, being cautious not to scratch the aluminum surfaces, and wipe them clean with a rag soaked in lacquer thinner or acetone. Install the oil strainer with a new gasket and tighten the bolts securely, then place a new oil pan gasket in the pan, ensuring the tabs are fully pressed into the gasket channel. Apply a 1/8-inch bead of silicone sealant to the corners of the block and where the oil pump meets the crankshaft rear seal-retainer, making sure to install the oil pan within 10 minutes after applying the sealant. Position the oil pan on the engine, install the pan-to-engine bolts, and tighten them in a criss-cross pattern, followed by retightening the oil pan-to-transaxle bolts. Complete the installation by reversing the removal steps and check the oil level on the dipstick, running the engine to check for leaks.