My Garage

My Account

Cart

Genuine Ford Focus Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Rod Bearings found

Ford Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-A$10.93 MSRP: $15.57You Save: $4.64 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-B$11.03 MSRP: $15.72You Save: $4.69 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-C$10.93 MSRP: $15.57You Save: $4.64 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: 3S7Z-6211-CA$7.66 MSRP: $10.91You Save: $3.25 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: AG9Z-6211-C$10.81 MSRP: $15.40You Save: $4.59 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: CM5Z-6211-C$11.89 MSRP: $16.93You Save: $5.04 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: 3S7Z-6211-AA$5.38 MSRP: $7.66You Save: $2.28 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: CM5Z-6211-A$11.33 MSRP: $16.93You Save: $5.60 (34%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: AG9Z-6211-A$10.81 MSRP: $15.40You Save: $4.59 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: AG9Z-6211-D$10.94 MSRP: $15.59You Save: $4.65 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: 3S7Z-6211-BA$7.59 MSRP: $10.82You Save: $3.23 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: F8CZ-6211-AA$14.99 MSRP: $20.82You Save: $5.83 (28%)Ships in 1-2 Business DaysFord Focus Connecting Rod Bearing

Part Number: AG9Z-6211-B$10.81 MSRP: $15.40You Save: $4.59 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: XS4Z-6211-AA$13.73 MSRP: $18.75You Save: $5.02 (27%)Ships in 1-2 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-G$11.04 MSRP: $15.73You Save: $4.69 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-H$10.96 MSRP: $15.62You Save: $4.66 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-D$11.04 MSRP: $15.73You Save: $4.69 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-F$11.04 MSRP: $15.73You Save: $4.69 (30%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: K2GZ-6211-A$86.15 MSRP: $125.95You Save: $39.80 (32%)Ships in 1-3 Business DaysFord Focus Connecting Rod Bearing

Part Number: EJ7Z-6211-E$10.96 MSRP: $15.62You Save: $4.66 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 27 Results

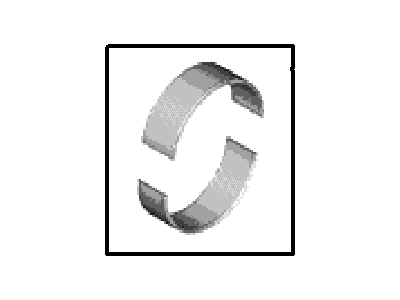

Ford Focus Rod Bearing

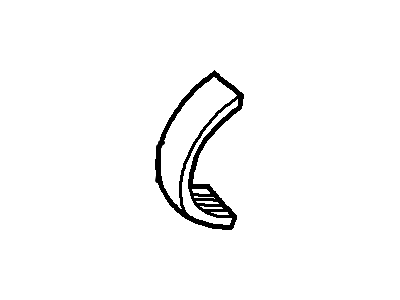

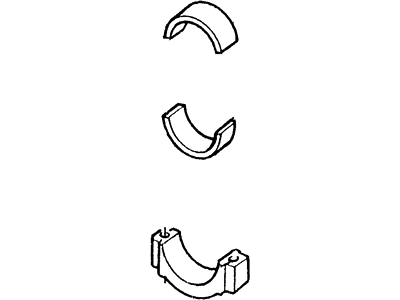

The Rod Bearing is an important part in Ford Focus vehicles since it bear the crankshaft and connecting rods to enable smooth rotation that requires low friction. Of these bearings, the most common type are the plain bearings, which usual come as bi-metal or tri-metal. grubbi Bearing of the Bi-metal Rod is composed of aluminum alloy, which is sometimes reinforced with silicone to increase its hardness and the tendency of seizing. However, the tri-metal Rod Bearings have a copper metal layer and the third layer has a composition of lead-tin-copper so it has more capacity than other ones. Many years, the Ford Focus used different types of Rod Bearing, and the use of sports modifications containing pieces of more sophisticated carbon and metal with special coating to increase elements of wear-resisting and anti-friction performance. These performance Rod Bearings come with particularity of eccentricities and can incorporate enlarged oil ways to feed the high-output engines. Ford Focus Rod Bearings are usually kept between 0.001" and 0.0035" and accurate oil clearance is vital that they last longer.

We provide a wide range of Ford Focus Rod Bearing at the best prices possible. If you need Ford Focus Rod Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Focus Rod Bearing Parts Questions & Experts Answers

- Q: What should be considered when examining and replacing Rod Bearing during an engine overhaul on Ford Focus?A:The main and connecting rod bearing shells should also be replaced during the engine overhaul when possible but if the old ones are kept it can be very informative on the condition of the engine. The stresses, which lead to bearing failure include lacks of lubricants, presence of dirt or any other foreign particle, engine overloading, and corrosion. This must be done irrespective of the reason before the unit is reassembled so that it does not recur. While comparing the bearing shells, take them out of their positions and place them on a flat surface so that any defects are aligned with the corresponding crankshaft journal while handling avoid touching the bearing surface in order not to introduce marks on it. Contamination may occur in the assembly line, by filters, and the crankcase ventilation system may contain machining metal chips, or abrasive material left during reconditioning. The former can become lodged in the soft bearing material while the latter scratch or gouge the shell and journal. Prevention is the key in this situation; that includes thorough cleaning of all parts and oil and filter changes. Common causes of lack of lubrication include overheating, overloading, leakage of oil, or obstruction of oil-feed passages so that the bearings heat up and wipe bearing material from the shell's backing. Driving also affects bearing life, acceleration, and deceleration at low speeds put a lot of pressure on the bearings thus causing the oil to be squeezed out; short trips also put a lot of stress to the bearings by not heating up at adequate levels. During assembly incorrect fitting leads to problems such as; the clearing between shells is reduced due to tight fitting shells and trapped dirt results to formation of high spots. One has to be very keen when reassembling bearing surfaces in order not to scratch or contaminate them.