My Garage

My Account

Cart

Genuine Ford Focus Crankshaft Pulley

Crankshaft Pulley Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Crankshaft Pulleys found

Ford Focus Crankshaft Pulley

Part Number: CM5Z-6312-C$25.21 MSRP: $36.85You Save: $11.64 (32%)Ships in 1-2 Business DaysFord Focus Crankshaft Pulley

Part Number: F1FZ-6312-A$60.82 MSRP: $88.92You Save: $28.10 (32%)Ships in 1-3 Business DaysFord Focus Crankshaft Pulley

Part Number: CM5Z-6312-B$104.46 MSRP: $152.72You Save: $48.26 (32%)Ships in 1-3 Business DaysFord Focus Crankshaft Pulley

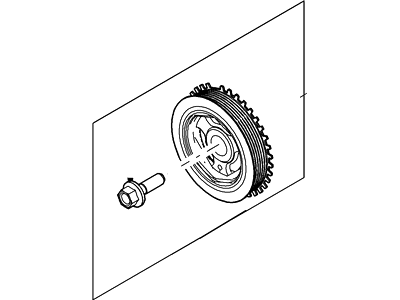

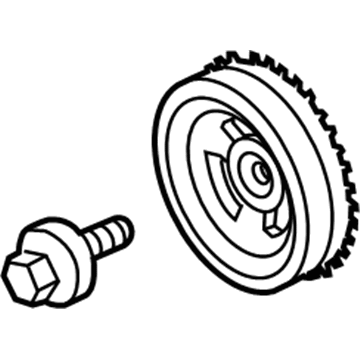

Part Number: 7U7Z-6312-A$181.26 MSRP: $265.00You Save: $83.74 (32%)Ships in 1-2 Business DaysFord Focus Crankshaft Pulley

Part Number: CM5Z-6312-K$60.69 MSRP: $88.73You Save: $28.04 (32%)Ships in 1-3 Business Days

Ford Focus Crankshaft Pulley

We provide a wide range of Ford Focus Crankshaft Pulley at the best prices possible. If you need Ford Focus Crankshaft Pulley, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Focus Crankshaft Pulley Parts Questions & Experts Answers

- Q: How to remove and install the crankshaft pulley in 2.0L zetec-e engine on Ford Focus?A:To have access to the auxiliary drivebelt the following actions should be performed, in case work to be done on the auxiliary drivebelt is not large, then the drivebelt should be removed; if, in turn, work is to be done on the crankshaft pulley, the aux. drivebelt should be disconnected somehow, for example, wound around and fixed firmly in place. It is recommended that if they are other tasks involved; which require the pulley to be off, should get the engine at TDC before proceeding to loosen the crankshaft pulley bolt. During the removal of the bolt of the pulley, the crankshaft must be locked or fixed in such a way that it cannot rotate; in this case, two holes in the face part of the pulley are used with a holding tool that is in the form of a forked piece made from metal strips. , This is done if the engine/transaxle is still in the vehicle Simply engage high gear and have someone step on the brake. If you merely hoist it out but do not unbolt it, prevent starter motor removal and lock the flywheel ring gear by jamming with a screwdriver into the bell housing. If the engine/transaxle has been removed completely, then use the method of flywheel removal is to be followed. This should not be used at any one time to lock the crankshaft as the timing pin is not strong enough to withstand the pressure and most probably will shear off. When you unscrew the pulley bolt, you have to take off the pulley and be keen on the way it is placed. For installation, though a pulley bolt is not necessarily needed to be replaced, however, in view of its resistance requirement to a high torque, it is recommended that the pulley bolt be replaced. The process of installation is the reverse of the removal; make certain the GL key way of the pulley fits to the locating key of the crank shaft; tighten the pulley bolt to rotation torque and lock the crank shaft in the same fashion when loosening it.

Related Ford Focus Parts

Browse by Year

2018 Crankshaft Pulley 2017 Crankshaft Pulley 2016 Crankshaft Pulley 2015 Crankshaft Pulley 2014 Crankshaft Pulley 2013 Crankshaft Pulley 2012 Crankshaft Pulley 2011 Crankshaft Pulley 2010 Crankshaft Pulley 2009 Crankshaft Pulley 2008 Crankshaft Pulley 2007 Crankshaft Pulley 2006 Crankshaft Pulley 2005 Crankshaft Pulley 2004 Crankshaft Pulley 2003 Crankshaft Pulley 2002 Crankshaft Pulley 2001 Crankshaft Pulley 2000 Crankshaft Pulley