My Garage

My Account

Cart

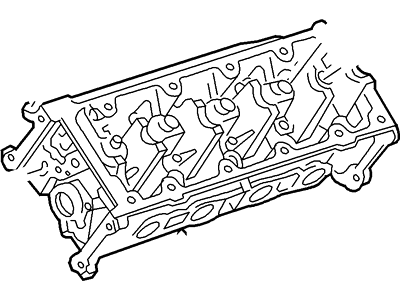

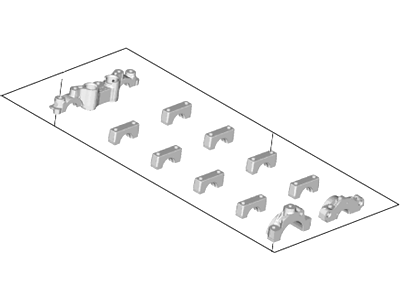

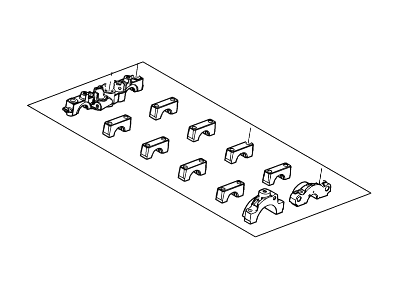

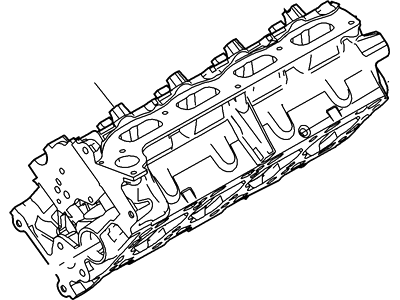

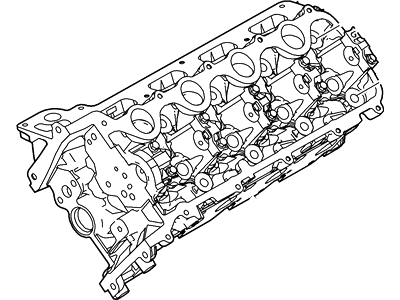

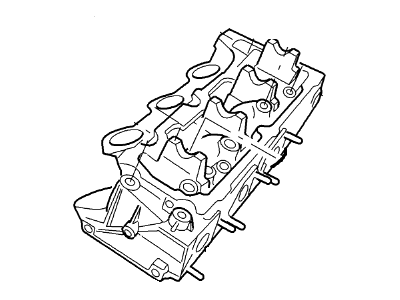

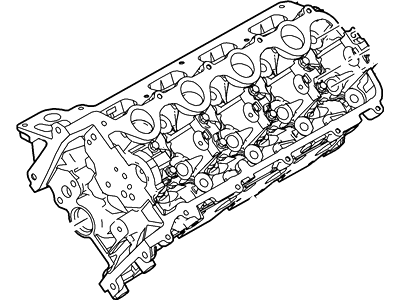

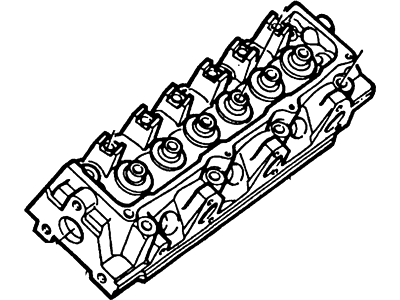

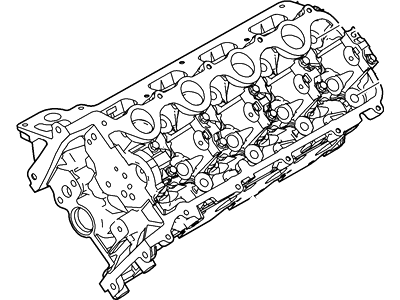

Genuine Ford Explorer Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

64 Cylinder Heads found

Ford Explorer Cylinder Head Assembly

Part Number: 4L3Z-6049-AA$605.57 MSRP: $824.62You Save: $219.05 (27%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: EJ7Z-6049-B$947.73 MSRP: $1294.62You Save: $346.89 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: CJ5Z-6049-C$783.65 MSRP: $1069.23You Save: $285.58 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: CJ5Z-6049-B$783.65 MSRP: $1069.23You Save: $285.58 (27%)Ships in 1-3 Business DaysFord Explorer Head Assembly - Cylinder

Part Number: 1L2Z-6049-LA$517.14 MSRP: $696.92You Save: $179.78 (26%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: DG1Z-6049-C$892.29 MSRP: $1218.46You Save: $326.17 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: K2GZ-6049-A$544.42 MSRP: $736.92You Save: $192.50 (27%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 9L3Z-6049-GB$275.03 MSRP: $371.67You Save: $96.64 (26%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 9L3Z-6049-E$2890.50 MSRP: $4247.69You Save: $1357.19 (32%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: JL3Z-6049-B$851.28 MSRP: $1245.54You Save: $394.26 (32%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 7L2Z-6049-C$647.85 MSRP: $892.68You Save: $244.83 (28%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: AT4Z-6049-D$892.29 MSRP: $1218.46You Save: $326.17 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 8L3Z-6049-B$275.03 MSRP: $371.67You Save: $96.64 (26%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: AA5Z-6049-J$827.33 MSRP: $1129.23You Save: $301.90 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: DG1Z-6049-A$589.46 MSRP: $795.38You Save: $205.92 (26%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 7U7Z-6049-AARH$650.05 MSRP: $903.03You Save: $252.98 (29%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: AA5Z-6049-K$851.97 MSRP: $1163.08You Save: $311.11 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: FG1Z-6049-A$851.97 MSRP: $1163.08You Save: $311.11 (27%)Ships in 1-3 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 9L3Z-6049-C$1930.90 MSRP: $4247.69You Save: $2316.79 (55%)Ships in 1-2 Business DaysFord Explorer Cylinder Head Assembly

Part Number: 7U7Z-6049-A$1528.45 MSRP: $2092.31You Save: $563.86 (27%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 64 Results

Ford Explorer Cylinder Head

We provide a wide range of Ford Explorer Cylinder Head at the best prices possible. If you need Ford Explorer Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Cylinder Head Parts Questions & Experts Answers

- Q: Is it more practical and economical for the home mechanic to purchase replacement cylinder heads rather than disassembling, inspecting, and reconditioning the originals on Ford Explorer?A:An assortment of new and remanufactured cylinder heads are easily procurable for most engine models at dealerships and auto spare parts selling centers. Because specialized tools are required for the procedures of disassembly for inspection and replacement, replacement parts for the heads may not be easily accessible, it would not be very cost effective for the home mechanic to perform the procedures of disassembly, inspection and reconditioning the heads and therefore it may be cheaper to buy replacement heads. They said that deconstruction includes eradication of intake and Exhaust Valves and many related parts. If not already done, then disconnect the rocker arm by using the spanner to loose the nut, the pivot ball and the flat rockers off the cylinder head studs. They can be labeled or placed in small plastic bags with legend to make it easy to refit them in their respective places in the valve train. Press down the springs on the first valve with the aid of a spring compressor then take out the lock on the valve stem using a needle-nose pliers or a magnet. Slowly let-go of the valve spring compressor and take out the retainer, sleeve if there is one, spring, and spring seat if there is one as well. Screw the valve off the head and take out the oil seal from the guide hole. If the valve binds in the guide, push it back into the head and take a fine file or whetstone and smoothen the area around the stem lock groove. Perform the same process for the other valves so it is easy to refurbish the different components belonging to each valve before reinstalling it. All valves and all other related parts that are going to be used later should be removed and stored in the best way possible manner; then, the head should be cleaned very well and it should be examined. In a scenario were an entire engine overhaul is being carried out, it is advisable that the processes of disassembly of the engine should be completed before proceeding to the cleaning as well as inspection of the cylinder heads.

Related Ford Explorer Parts

Browse by Year

2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head