My Garage

My Account

Cart

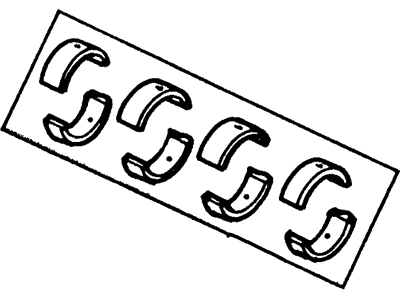

Genuine Mercury Capri Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Rod Bearings found

Mercury Capri Rod Bearing

Rod Bearing of Mercury Capri cars function as vital components that enable linkage rotation between the connecting rod and crankshaft thus minimizing friction alongside wear effects. The reduction of engine friction stands as critical to protect moving metal components which extends both performance quality and lifespan. Mercury Capri vehicles use Rod Bearing that exist in two versions known as bi-metal and tri-metal and demonstrate different properties through their material composition. Bi-metal bearings consist of aluminum alloy linings and tri-metal bearings incorporate copper in between two layers of aluminum alloy and lead-tin-copper alloy which improves both strength and fatigue resistance. When selecting Rod Bearing for engine applications proper sizing stands as the fundamental factor to preserve engine performance because incorrect fitments bring about clearance issues that might harm components. Engine Rod Bearing identification tags help find the precise substitution pieces while a measurement of the bearing cavity serves as an alternative solution for identification purposes. Regular inspections must be performed to identify worn Rod Bearing so vehicle owners should replace them in a timely manner to maintain the smooth operation of Mercury Capri engines.

We provide a wide range of Mercury Capri Rod Bearing at the best prices possible. If you need Mercury Capri Rod Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Capri Rod Bearing Parts Questions & Experts Answers

- Q: What should be done with old bearings during an engine overhaul, and why is it important to examine them on Mercury Capri?A:At anytime an engine is overhauled it becomes necessary to replace main and connecting rod bearings while retaining the old ones as they can tell a lot about the engine. General causes of bearing failure include inadequate lubrication, polluted lubricants, overloading, and corrosion and all these must be corrected before the bearings can be reused. When examining the bearings, they need to be unloaded from their place and placed on a clean surface so that it may be easy to match the defects with the crankshaft journal. These particles can get into the engine when the engine is being assembled, with the filter or during the course of machining for they can penetrate deep into the bearing material and remain therein, while the larger ones cause scoring. It is from such failures that one can chose to emphasize the need for cleaning every part of the vehicle and following recommended times for oil change and filter replacement. The main causes include excess temperature, overcharge, oil loss, or blocked oil supply passages, with severe effect in that the bearing material is scraped off. Some driving behavior also affect bearing years; for example, maneuvering at slow speeds puts full throttle which can generate loads that expel oil and short trips result to corrosion. Also, improper installation like backlash of tight-fitting bearing or foreign objects trapped within can lead to oil starvation, and therefore failure.