My Garage

My Account

Cart

Genuine Mercury Capri Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Oil Pumps found

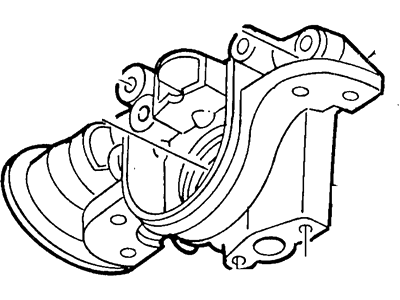

Mercury Capri Oil Pump

Part Number: E63Z6600A$10.39 MSRP: $14.44You Save: $4.05 (29%)Ships in 1-2 Business Days

Mercury Capri Oil Pump

The Mercury Capri Oil Pump assumes a vital function as it delivers pressurized oil throughout the system to supply lubrication and cooling functions to bearings and pistons of the engine. Multiple components such as gears and springs unite in this device to carry out this operational procedure. The oiling system obtains oil from the sump after filtering before distributing it through the engine while sustaining required oil pressure that supports performance. The Capri has utilized three different types of Oil Pump known as direct drive and gear drive and chain drive units for its oil circulation system. The unique mounting positions of these Mercury Oil Pump types differ because direct drive pumps surround the crankshaft whereas gear and chain drive pumps position on the side. Regular inspection coupled with maintenance activities for the Mercury Capri Oil Pump matter many during engine rebuilds because they preserve optimum performance while avoiding damage to engine parts.

We provide a wide range of Mercury Capri Oil Pump at the best prices possible. If you need Mercury Capri Oil Pump, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Capri Oil Pump Parts Questions & Experts Answers

- Q: How do you remove and install the oil pump and ensure proper oil pressure in four cylinder engine on Mercury Capri?A:Remove the Oil Pan. Next, take off the nut securing the pick-up tube to the engine, followed by the bolts securing the pump to the engine. Remove the pump and pick-up tube as an assembly, then separate them once they are off the engine. The pump intermediate shaft should drop out of the bottom of the distributor shaft during this process. If there is any possibility that the pump is faulty or if an engine overhaul is being performed, replace the pump, as a faulty pump can ruin an otherwise good engine. Before installation, prime the pump by holding it with the pick-up tube up and pouring a few ounces of clean oil into the inlet screen. Turn the pump driveshaft by hand until oil comes out the outlet. Install the pump intermediate shaft with the collar end in the engine block, ensuring the shaft seats in the distributor. Hold the shaft in place and install the pump and oil pan, making sure to tighten the bolts to the specified torque. Add oil to the engine, then start it and ensure the oil pressure comes up. If it doesn't come up within 10 or 15 seconds, shut off the engine immediately and investigate the cause of the problem, as continued running without oil pressure can severely damage the moving parts. Finally, check for oil leaks.