My Garage

My Account

Cart

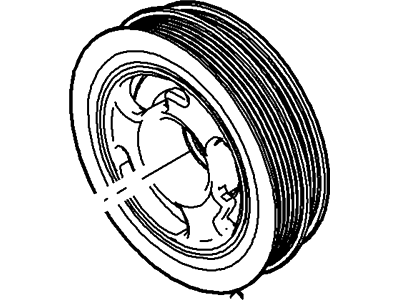

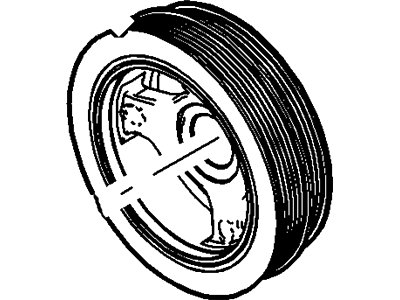

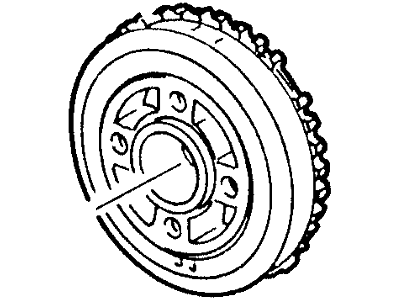

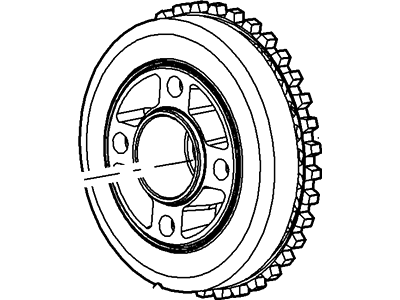

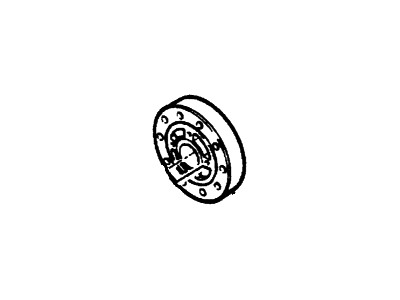

Genuine Ford Taurus Crankshaft Pulley

Crankshaft Pulley Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Crankshaft Pulleys found

Ford Taurus Crankshaft Pulley

The Performance Crankshaft Pulley is an important part in the Ford Taurus vehicles, as it transfers the power from the engine to other products like the power, A/C compressor and the alternation. The Performance Crankshaft Pulley operates through getting torque directly from the crankshaft of the engine and as such, increases efficiency and performance. Moreover it acts as a harmonic balancer which reduces vibrations experienced by the engine in its operation process. Different Ford Taurus models have incorporated different types of Performance Crankshaft Pulley throughout the years with each aimed at enhancing performance in unique manner. These deviations could be in weight, material or design and hence influence on the balance and response of the engine.

We provide a wide range of Ford Taurus Crankshaft Pulley at the best prices possible. If you need Ford Taurus Crankshaft Pulley, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Taurus Crankshaft Pulley Parts Questions & Experts Answers

- Q: How to remove and install the crankshaft pulley and ensuring correct engine timing in four cylinder engine on Ford Taurus?A:Take off the drivebelt, and the brake vacuum pump. Remove the valve cover off. Disconnect the rear intake camshaft bearing cap by undoing the bolts and cap; in order to freeze movement of the camshaft, place a wrench on the flats of the camshaft, then, unscrew and remove the brake vacuum pump adapter from the end of the camshaft. Undo the bolts shown in Fig. 6.1 and withdrawal the right driveaxle intermediate shaft bracket. With the help of the camshaft and crankshaft position indicator set the engine at the top dead center. The crankshaft essentially has to be immobilized to check free rotation while the bolt of the crankshaft pulley is loosened; to this effect, a preferable method is to position a strap around the crankshaft pulley and tighten it to grip the crankshaft, then go ahead and use a 1/2 inch drive air or electric impact wrench to remove the crankshaft bolt. Lack of firmly securing the crankshaft pulley can cause the crankshaft to move and the cranking bolt to break leading to the damages of the engine. It is especially important not to lock the crankshaft using timing pin or camshaft alignment tool as these are calibration tools. Loosen the pulley bolt after which the pulley and the back diamond washer can be disconnected. Get a 'new' pulley bolt and a diamond washer. For assembly, replace the existing diamond washer with a new one on the nose of the crankshaft, apply a thin layer of clean engine oil on the crankshaft front seal and finally put on the crankshaft pulley. You should replace the seal if it has been found to show signs of leakage, prior to fitting the crankshaft pulley. Let the intake end of the camshaft be aligned with the help of special tool #303-1565 that should be installed in the mentioned part of the camshaft ; Put the Crankshaft Position (CKP) sensor alignment tool(#303-1521) on the sensor, then put a new crankshaft pulley bolt and washer on hand tighten only and then remove the tool. After that while still using the strap wrench to hold the pulley, tighten the crankshaft pulley bolt in stages reaching the torque required. It is not allowed to tighten the crankshaft pulley bolt with an impact gun. Take out the timing pin from the cylinder block as well as camshaft alignment tool. Depress the spring-loaded brake that holds the crankshaft pulley by placing the fingers between the pulley and the brake and turn the engine clockwise two full turns while observing how the tool interacts with the spark plugs. Should there be any resistance, then this should be investigated immediately, as this may imply wrong timing and an interference between the valves and the pistons. The engine should then be rotated again until it reaches TDC and the rotation should only be made in clockwise direction. After that, screw the timing pin into the cylinder block. Place the crankshaft at TDC and engage the tooth on the crankshaft pulley with the CKP sensor center line, and then fit the camshaft aligning tool to check the camshafts position. If for some reasons the tool cannot be installed it is necessary to correct the engine timing through the TDC. This is done when the camshaft alignment tool is in place, the timing pin is properly in place and also when the crankshaft pulley TDC tooth is aligned with the CKP sensor center line at the same time. After getting the right engine timing, you can then take out every tool used in aligning, the bolts and the timing pin plug. The rest of installation is, therefore, the antithesis of removal.

Related Ford Taurus Parts

Browse by Year

2019 Crankshaft Pulley 2018 Crankshaft Pulley 2017 Crankshaft Pulley 2016 Crankshaft Pulley 2015 Crankshaft Pulley 2014 Crankshaft Pulley 2013 Crankshaft Pulley 2012 Crankshaft Pulley 2011 Crankshaft Pulley 2010 Crankshaft Pulley 2009 Crankshaft Pulley 2008 Crankshaft Pulley 2007 Crankshaft Pulley 2006 Crankshaft Pulley 2005 Crankshaft Pulley 2004 Crankshaft Pulley 2003 Crankshaft Pulley 2002 Crankshaft Pulley 2001 Crankshaft Pulley 2000 Crankshaft Pulley 1999 Crankshaft Pulley 1998 Crankshaft Pulley 1997 Crankshaft Pulley 1996 Crankshaft Pulley 1995 Crankshaft Pulley 1994 Crankshaft Pulley 1993 Crankshaft Pulley 1992 Crankshaft Pulley 1991 Crankshaft Pulley 1990 Crankshaft Pulley 1989 Crankshaft Pulley