My Garage

My Account

Cart

Genuine Ford Ranger Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

34 Pistons found

Ford Ranger Piston

Part Number: E9TZ-6108-DB$19.28 MSRP: $26.34You Save: $7.06 (27%)Ships in 1 Business DayFord Ranger Piston

Part Number: 5M8Z-6108-A$145.46 MSRP: $212.67You Save: $67.21 (32%)Ships in 1-3 Business DaysFord Ranger Piston

Part Number: 4U7Z-6108-A$61.21 MSRP: $85.03You Save: $23.82 (29%)Ships in 1-2 Business DaysFord Ranger Piston

Part Number: LB5Z-6108-A$433.81 MSRP: $639.83You Save: $206.02 (33%)Ships in 1-3 Business DaysFord Ranger Piston And Pin Assembly

Part Number: 2F1Z-6108-CA$32.60 MSRP: $45.29You Save: $12.69 (29%)Ships in 1-2 Business DaysFord Ranger Piston

Part Number: 5M8Z-6108-B$132.24 MSRP: $193.33You Save: $61.09 (32%)Ships in 1-3 Business DaysFord Ranger Piston

Part Number: 5M8Z-6108-C$119.70 MSRP: $175.00You Save: $55.30 (32%)Ships in 1-3 Business DaysFord Ranger Piston And Pin Assembly

Part Number: 2F1Z-6108-FA$17.34 MSRP: $24.09You Save: $6.75 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 34 Results

Ford Ranger Piston

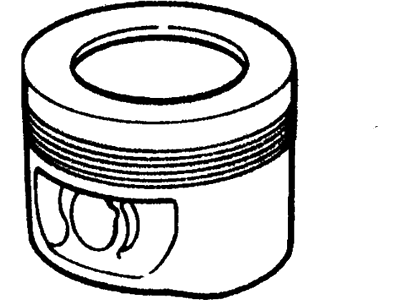

Piston in Ford Ranger vehicles is the internal combustion engine part that transforms combustion power to the energy needed in the movement of the car. To achieve this it translates pressures created from a gases expansion process to the crankshaft to ensure optimum engine performance. When it comes to the Ford Ranger pistons, they are customarily made of alloy materials for their light weight and high rigidity, high-performance pistons may even use forged or billet pistons. Many kinds of pistons have been used over the years for Ford Ranger models including trunk pistions for both petrol and diesel engines, the latter of which takes side forces and has oil rings for its lubrication use. Also, racing pistons are different in their great lightweight and their strong material, which is ideal for high RPM used in racing engine.

We provide a wide range of Ford Ranger Piston at the best prices possible. If you need Ford Ranger Piston, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Ranger Piston Parts Questions & Experts Answers

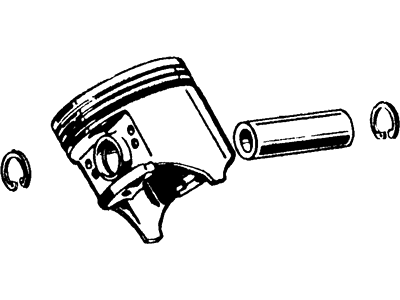

- Q: How to install piston/connecting rod assemblies and check oil clearance on 1993-2011 Ford Ranger?A:Be certain that cylinder walls in each of the pistons are immaculate and top edge of each cylinder is slightly beveled before fixing the piston and connecting rod assemblies and make sure that Crankshaft has been fitted. Take off the cap of the number one connecting rod, and remember the marks made while removing the cap, and clean the bearing surface with a clean cloth. In the connecting rod bearing oil clearance check, clean the back side of the new upper bearing insert and place it in the connecting rod, the tab should fit into the recess, without hammering insert it. Do this for the lower bearing insert in the rod cap and ensure that all mating surfaces are clean and oil free. Align each of the gaps in the piston ring on the piston, apply clean engine oil on the piston and on the rings, then place the piston ring compressor in a manner that the skirt of the piston is slightly outside. Turn the crankshaft till the number one connecting rod journal is at BDC while apply some oil on the cylinder walls. Place the piston/connecting rod assembly into the cylinder bore with the arrow pointed towards the front of the engine, where the oil squirt hole on each of the connecting rod is to point to the middle of the engine. Rub your fingers across the ring compressor to ensure that it abuts the block and do the same to the piston while sliding the connecting rod over the crankshaft journal, if you feel any resistance at this stage, do not force the connecting rod onto the journal, nuts and bolts may be in the way. After the installation, check the oil clearance of connecting rod bearing using Plastigage, by making the width of the crushed material to follow the specifications. If the clearance is incorrect then ensure that no dirt or oil impacted on the clearance measurement as well as check on the journal diameter. Remove the plastigage from the rod journal and bearing face and apply a fresh layer of moly-base grease or engine assembly lube it to its respective areas and replace the connect rod and cap tighten the nuts to the specified torque value in a three step manner. Follow the same process for rest of the pistons and connecting rods that include cleaning the bearing inserts and the connecting rods, orientating the connecting rods correctly, lubricating the cylinder walls, and testing for binding with the help of rotating the Crank shaft. Last, but not the least is to check the connecting rod endplay and measure it with reference to the specifications written for it, if there is any variation, it will be advisable to resize the rods.

Related Ford Ranger Parts

Browse by Year

2023 Piston 2022 Piston 2021 Piston 2020 Piston 2019 Piston 2011 Piston 2010 Piston 2009 Piston 2008 Piston 2007 Piston 2006 Piston 2005 Piston 2004 Piston 2003 Piston 2002 Piston 2001 Piston 2000 Piston 1999 Piston 1998 Piston 1997 Piston 1996 Piston 1995 Piston 1994 Piston 1993 Piston 1992 Piston 1991 Piston 1990 Piston 1989 Piston 1988 Piston 1986 Piston 1985 Piston 1984 Piston 1983 Piston