My Garage

My Account

Cart

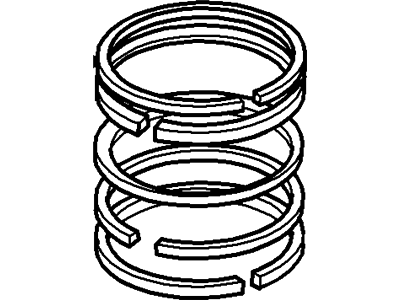

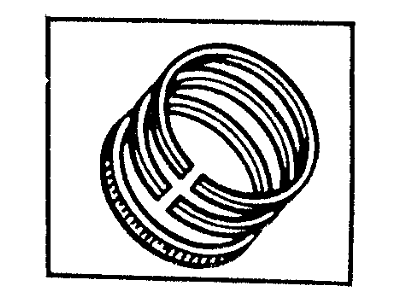

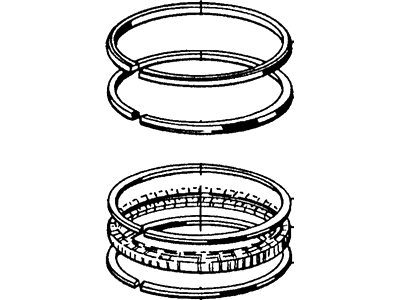

Genuine Ford Ranger Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Piston Ring Sets found

Ford Ranger Piston Ring Kit

Part Number: K2GZ-6148-A$32.18 MSRP: $45.83You Save: $13.65 (30%)Ships in 1-3 Business DaysFord Ranger Piston Ring Kit

Part Number: 2U3Z-6148-AA$43.26 MSRP: $62.15You Save: $18.89 (31%)Ships in 1-3 Business DaysFord Ranger Piston Ring Kit

Part Number: E6TZ6148A$22.89 MSRP: $31.27You Save: $8.38 (27%)Ships in 1-2 Business DaysFord Ranger Piston Ring Kit

Part Number: BL5Z-6148-A$68.93 MSRP: $95.75You Save: $26.82 (29%)Ships in 1-2 Business DaysFord Ranger Piston Ring Kit

Part Number: K2GZ-6148-B$93.44 MSRP: $144.47You Save: $51.03 (36%)Ships in 1-3 Business DaysFord Ranger Piston Ring Kit

Part Number: 4F1Z-6148-CA$67.78 MSRP: $94.15You Save: $26.37 (29%)Ships in 1-2 Business DaysFord Ranger Piston Ring Kit

Part Number: F87Z-6148-AA$46.97 MSRP: $65.25You Save: $18.28 (29%)Ships in 1-2 Business DaysFord Ranger Piston Ring Kit

Part Number: 4F1Z-6148-EA$106.38 MSRP: $147.78You Save: $41.40 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 26 Results

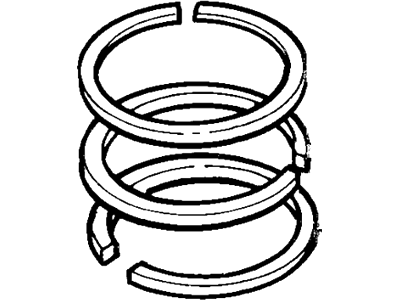

Ford Ranger Piston Ring Set

The Piston Ring Set in Ford Ranger vehicles has the following tasks, among others, to seal the combustion chamber to reduce gases leakage, to facilitate heat transfer and to control oil utilization. These are steel or cast iron bands whose functions are to reduce the friction and to seal, this is an important factor for more efficiency for the engine as well as its durability. These have however changed with time with current designs depending on thinner Piston Ring Sets that have less friction and are able to provide better sealing for the cylinders. The current configurations may comprise of 1mm top and second rings, 2mm oil control rings and these are made of hard materials such as steel or ductile iron. These development enables improvement on the piston design and hence improving its performance, which is helpful in improving the overall efficiency of the engine of the Ford Ranger.

We provide a wide range of Ford Ranger Piston Ring Set at the best prices possible. If you need Ford Ranger Piston Ring Set, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Ranger Piston Ring Set Parts Questions & Experts Answers

- Q: How should the piston ring end gaps be checked and corrected before installation on 1993-2011 Ford Ranger?A:Whatever the position on Piston ring side clearance, before installing the new piston rings, the ring end gaps must be checked, as they should. Make sure that the piston/connecting rod assemblies and the new ring sets are laid out in pairs with same piston and cylinder for the end gap measurement and during the time of final engine assembling. Slip the top ring into the first cylinder with the ring close to the cylinder liner bottom through pushing with the top of the piston. To determine the end gap, one has to fit feeler gauges between the ends of the ring until one is achieved which fits with slight friction. In case the spacing is either of it larger or smaller than the claimed value, check the rings once again. If the gap is too narrow, it has be increased to ensure that it does not close up during the running of the engine since this will cause a lot of damage. This can be done by making a point of filing the ring ends while being very careful not to file in from the inside out. More end gap is not an issue if it is not 0.040-inch and above so ensure the correct rings for the engine are identified. Perform the same on all other rings in the first cylinder and the remaining cylinders with matched rings, pistons, and cylinders. After that, use a finger to examine the end gap of the ring, and if necessary correct on the required dimension, and finally fit the rings on the pistons; the oil control ring has three parts. Insert the spacer/expander into the groove with the anti-rotation tang entering the drilled hole and then install the lower side rail; to prevent the damaging of the piston ring, do not make use of the piston ring installation tool. Align the narrow flat edge of the side rail and insert it in to the groove and then in the same manner insert the upper side rail of the bed. After the installation of the three oil ring components, this must be ensured that both side rails are now able to rotate in this groove. Next, secure the middle ring with the stamped side up, and depending on the ring manufacture the instruction on the package should be followed. One disadvantage when using it is that the top and middle rings are inter-changeable since they are made with different cross-sections. The middle piston ring should be fitted using a piston ring installation tool, with the identification mark uppermost while the ring is put in the middle groove without compressing it fully. Last of all screw on the top ring in the similar way being keen to note the mark facing upwards and do not interchange the top and middle rings then do the same to the other pistons and rings.

Related Ford Ranger Parts

Browse by Year

2023 Piston Ring Set 2022 Piston Ring Set 2021 Piston Ring Set 2020 Piston Ring Set 2019 Piston Ring Set 2011 Piston Ring Set 2010 Piston Ring Set 2009 Piston Ring Set 2008 Piston Ring Set 2007 Piston Ring Set 2006 Piston Ring Set 2005 Piston Ring Set 2004 Piston Ring Set 2003 Piston Ring Set 2002 Piston Ring Set 2001 Piston Ring Set 2000 Piston Ring Set 1999 Piston Ring Set 1998 Piston Ring Set 1997 Piston Ring Set 1996 Piston Ring Set 1995 Piston Ring Set 1994 Piston Ring Set 1993 Piston Ring Set 1992 Piston Ring Set 1991 Piston Ring Set 1989 Piston Ring Set 1988 Piston Ring Set 1987 Piston Ring Set 1986 Piston Ring Set 1985 Piston Ring Set 1984 Piston Ring Set 1983 Piston Ring Set