My Garage

My Account

Cart

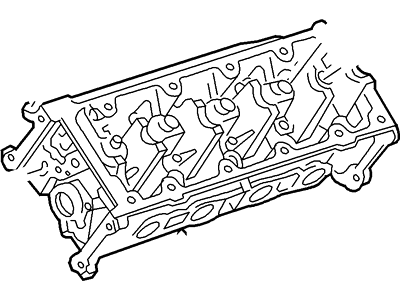

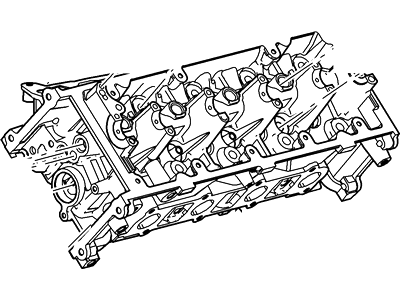

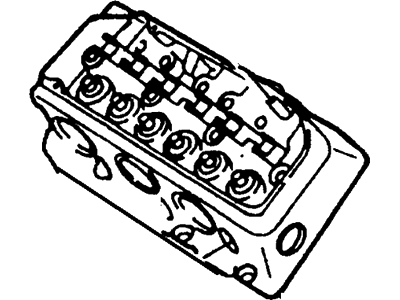

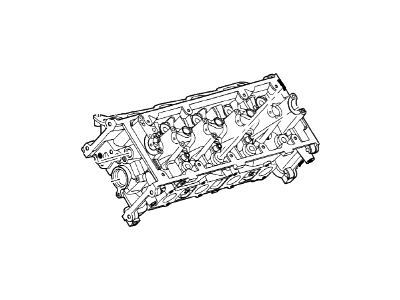

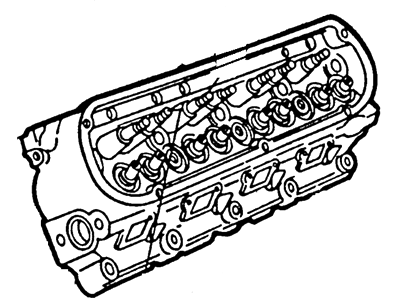

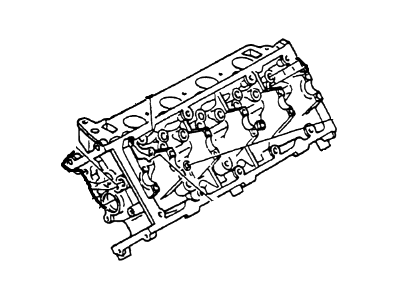

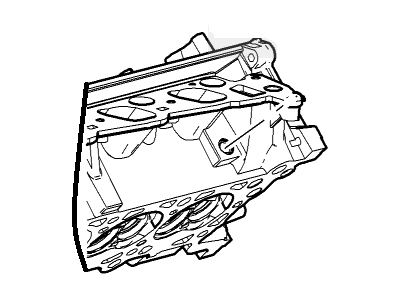

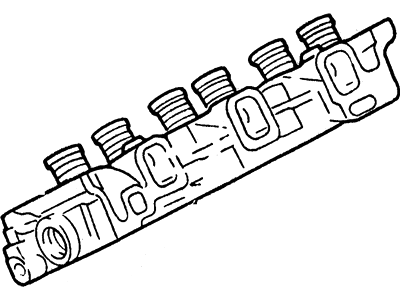

Genuine Mercury Grand Marquis Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Cylinder Heads found

Mercury Grand Marquis Cylinder Head Assembly

Part Number: 4L3Z-6049-AA$605.57 MSRP: $824.62You Save: $219.05 (27%)Ships in 1-2 Business DaysMercury Grand Marquis Head Assembly - Cylinder

Part Number: 1L2Z-6049-LA$517.14 MSRP: $696.92You Save: $179.78 (26%)Ships in 1-3 Business DaysMercury Grand Marquis Cylinder Head Assembly

Part Number: 1W7Z-6049-AARH$605.57 MSRP: $824.62You Save: $219.05 (27%)Ships in 1-2 Business DaysMercury Grand Marquis Cylinder Head Assembly

Part Number: 6W7Z-6049-AA$517.14 MSRP: $696.92You Save: $179.78 (26%)Ships in 1-3 Business DaysMercury Grand Marquis Cylinder Head Assembly

Part Number: F4AZ-6049-A$6.90 MSRP: $10.31You Save: $3.41 (34%)Ships in 1-3 Business DaysMercury Grand Marquis Cylinder Head Assembly

Part Number: 2C5Z-6049-AA$60.05 MSRP: $82.05You Save: $22.00 (27%)

Mercury Grand Marquis Cylinder Head

We provide a wide range of Mercury Grand Marquis Cylinder Head at the best prices possible. If you need Mercury Grand Marquis Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Grand Marquis Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and install cylinder heads in 4.6L V8 engine on Mercury Grand Marquis?A:Bend back the clamp on the cable and disconnect it from the negative battery terminal, take off the valve cover(s) as well. Next, set the intake manifold and the Timing Chain cover aside, and then take out the timing chains, make sure to make use of the camshaft holding fixture so as to lock the camshafts during the entire procedure of reassembly. Disconnect the Exhaust Manifold from the exhaust pipe(s) and remove the positive battery cable bracket mounted at the rear of the cylinder head and remove the bolt at the back of the right cylinder head. unscrew the positive battery cable and remove the bracket from the stud at the top right of the cylinder head so as to retrieve it when removing the cylinder head. At the rear of the right cylinder head, remove the ground strap and disconnect the heater hose at the pipe which is fixed at the rear of the right side cylinder head but retained at the head during removal. If necessary one can remove the exhaust manifold(s) although it may be easier to leave the manifold connected to the head during removal due to restricted access. To remove the head bolts, turn them back by a quarter turn at a time with a breaker bar and a deep socket if necessary and use the reverse of the tightening pattern which should be easily done by hand. The lower rear head bolt on the right cylinder head cannot be reached because of the position of the heater/air conditioning case, and the bolt is to be held in place with a rubber band during cylinder head removal, and must be discarded as the new bolts have to be used when reinstalling both the heads. Take off the head(s) above the engine, if it is necessary tear gasket, put a wood between the head and put a hammer to drive it, do not pry between a head and the cylinder block, it can be damaged. Place the heads in wood blocks to protect the gasket sealing areas and then remove the old head gasket(s); there are right hand and left hand heads and the gaskets are different and should not be interchanged. It is necessary to clean the mating surfaces of the cylinder heads and block before their installation and, for this, a gasket scraper should be used, and the cleaned areas should be washed with lacquer thinner or acetone in order to remove oil that weakens the seal. Examine the block and head mating surfaces for flaws, using file for minor roughness and if it is severe, then it might require machining. The taps should be used to clean the threads in the head bolt holes because they cause variation in torque readings due to presence of dirt and corrosion. Place the new gaskets upon the appropriate cylinder banks over the alignment dowels with attention to their interchangeability. Finally before replacing the cylinder heads back on the block rotate the crankshaft counter clockwise about 9 O'clock in order to prevent such damages like the pistons rods or the valve train parts. Place the head(s) on the block without interfering with the gaskets as a new head bolt will be needed and follow the recommended torque sequence tightened with three steps where each bolt to be given additional turns have to be marked with stripe. Tightening procedure to 90 degrees, then to 2 extra turns using specified angle so as to be in the range of the bolt stretch to obtain the right load on the head gasket. The other installation procedures are the opposite of the removal processes and upon completion of the installation change the engine oil and filter, start the engine and look for any oil and coolant leaks respectively.

Related Mercury Grand Marquis Parts

Browse by Year

2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head