My Garage

My Account

Cart

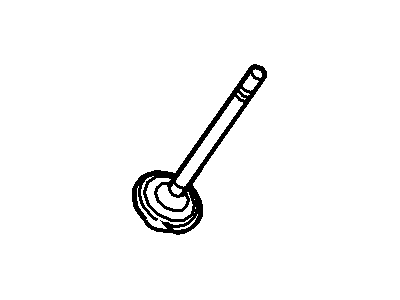

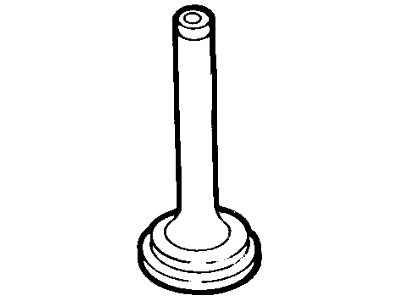

Genuine Mercury Grand Marquis Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Exhaust Valves found

Mercury Grand Marquis Exhaust Valve

Part Number: XL3Z-6505-AA$65.54 MSRP: $96.67You Save: $31.13 (33%)Mercury Grand Marquis Exhaust Valve

Part Number: 6W7Z-6505-BA$55.48 MSRP: $81.83You Save: $26.35 (33%)Ships in 1-2 Business DaysMercury Grand Marquis Exhaust Valve

Part Number: F1AZ-6505-A$16.71 MSRP: $22.84You Save: $6.13 (27%)Mercury Grand Marquis Valve Exhaust

Part Number: E9SZ6505A$18.13 MSRP: $24.77You Save: $6.64 (27%)Ships in 1-2 Business DaysMercury Grand Marquis Exhaust Valve

Part Number: F6AZ-6505-AB$31.92 MSRP: $43.61You Save: $11.69 (27%)Ships in 1-2 Business DaysMercury Grand Marquis Exhaust Valve

Part Number: F3LY-6505-A$30.54 MSRP: $43.50You Save: $12.96 (30%)Mercury Grand Marquis Exhaust Valve

Part Number: E43Z-6505-A$48.37 MSRP: $69.50You Save: $21.13 (31%)

Mercury Grand Marquis Exhaust Valve

We provide a wide range of Mercury Grand Marquis Exhaust Valve at the best prices possible. If you need Mercury Grand Marquis Exhaust Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Grand Marquis Exhaust Valve Parts Questions & Experts Answers

- Q: Should servicing of valves, valve seats, and valve guides be done by a professional on Mercury Grand Marquis?A:Because of the nature of the position and the specific instruments and equipment needed, performing the valve job as it takes to service the valves, valve seats, and valve guides should be handled by an expert. An amateur can unbolt the head, open it to inspection and semi-cleaning before delivering the assembly to a dealership or an automotive machine where the actual work will be done. It makes it possible to determine the state of components of heads and valve trains, know what work is still required, what new parts may be needed when cooperating with an automotive machine shop. The dealer service department or automotive machine shop is retained for the relief of valves and springs, valve face necessary reconditioning or new, reconditioning of valve guides, checking and replacing of valve springs, spring retainers, rotators and keepers if necessary, valve seal replacement, assembly of valve components, and correct installed spring height check also. Also, if its surface has warping, the cylinder head gasket surface will be resurfaced. After the valve job is done by a professional the head will be almost as new as it was when it first came out the factory. On its arrival, the head must also be washed to reduce the amount of metal particles and abrasive grit that might still be present after serving the valves or resurfacing, and compressed air if available should be used to blow out all the oil holes and passages before fitting on the engine.

Related Mercury Grand Marquis Parts

Browse by Year

2011 Exhaust Valve 2010 Exhaust Valve 2009 Exhaust Valve 2008 Exhaust Valve 2007 Exhaust Valve 2006 Exhaust Valve 2005 Exhaust Valve 2004 Exhaust Valve 2003 Exhaust Valve 2002 Exhaust Valve 2001 Exhaust Valve 2000 Exhaust Valve 1999 Exhaust Valve 1998 Exhaust Valve 1997 Exhaust Valve 1996 Exhaust Valve 1995 Exhaust Valve 1994 Exhaust Valve 1993 Exhaust Valve 1992 Exhaust Valve 1989 Exhaust Valve 1988 Exhaust Valve 1987 Exhaust Valve 1986 Exhaust Valve 1985 Exhaust Valve 1984 Exhaust Valve 1983 Exhaust Valve 1982 Exhaust Valve 1981 Exhaust Valve 1980 Exhaust Valve