My Garage

My Account

Cart

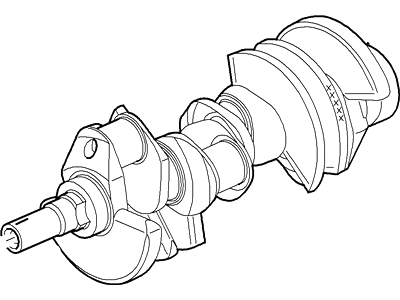

Genuine Mercury Grand Marquis Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Crankshafts found

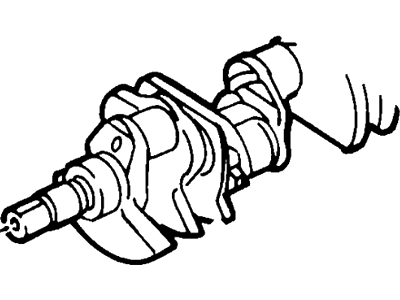

Mercury Grand Marquis Crankshaft Assembly

Part Number: 2C5Z-6303-BA$292.11 MSRP: $430.83You Save: $138.72 (33%)Mercury Grand Marquis Crankshaft Assembly

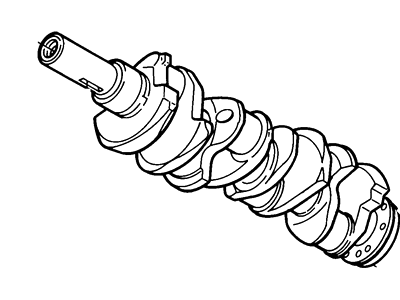

Part Number: 2C5Z-6303-AA$292.11 MSRP: $430.83You Save: $138.72 (33%)

Mercury Grand Marquis Crankshaft

We provide a wide range of Mercury Grand Marquis Crankshaft at the best prices possible. If you need Mercury Grand Marquis Crankshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Grand Marquis Crankshaft Parts Questions & Experts Answers

- Q: How to remove the crankshaft on Mercury Grand Marquis?A:It is impossible to remove the crankshaft until the engine is removed from the car, knowing that the flywheel or driveplate and the vibration damper are attached, the timing chains or gears, oil pan, oil pump, and piston/connecting rod assemblies are other features that have to be removed. Crankshaft endplay should be checked before starting the crankshaft removal operation; first, install a dial indicator as shown in figure 3 so that it can touch the end of the crankshaft. Stand the crankshaft rearward and set the dial indicator to zero, prostrate the crankshaft forward and read the dial indicator; endplay is defined by the movement. If the stationary geometry is distorted beyond the limit, the thrust surfaces of the worn wheel should be inspected For that there is no worn wheel the problem must be solved by new main bearings. In the absence of a dial indicator, feeler gauges can also be used where the crank shaft is hammered or pried towards the front and the clearance is noted with the feeler gauges. Make sure that the main bearing caps are stamped to show their positions; these should be sequentially stamped from the front; if there are no such markings apply them yourself. On 5.0L engines, the thrust bearing is to be found at the number three main bearing cap and having upper and lower thrust bearing shells. Turn the main bearing cap bolts in a clockwise direction in stages, to allow them to be easily unscrewed to get a loose fit, and make sure the stud bolts are replaced back in their respective positions on when re-tightening. The 4.6L motors have considerably higher amounts of bolts that hold the main caps, which demands elaborate procedures for affixation and detachment. Take out all side bolts, snug the jacking screws on the main bearing cap at least, and then remove the main bearing cap bolts in the reverse order that is used in tightening and these bolts are not to be used again. Using a soft face hammer tap on the caps to loosen them, using bolts as a pry-bar, lift the crankshaft out very carefully as it is very heavy, it is best done with another person. Put back the lower caps to their respective positions and loosely fasten the bolts of the bearing inserts.

Related Mercury Grand Marquis Parts

Browse by Year

2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1996 Crankshaft 1995 Crankshaft 1994 Crankshaft 1993 Crankshaft 1991 Crankshaft 1990 Crankshaft 1989 Crankshaft 1988 Crankshaft 1987 Crankshaft 1986 Crankshaft 1985 Crankshaft 1984 Crankshaft 1983 Crankshaft