My Garage

My Account

Cart

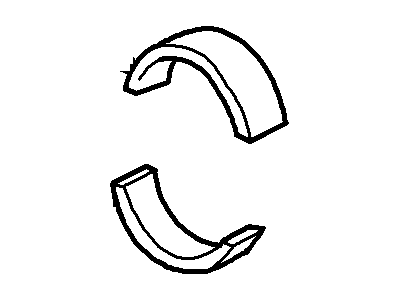

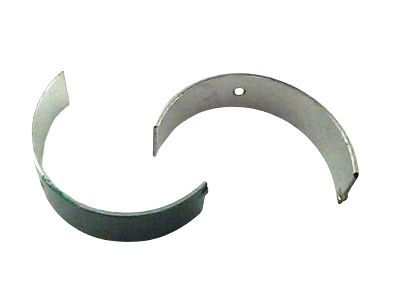

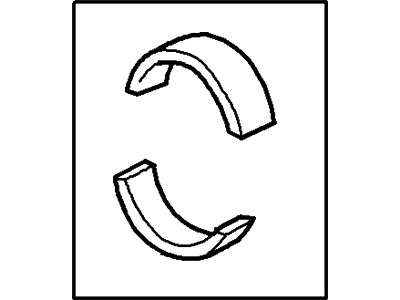

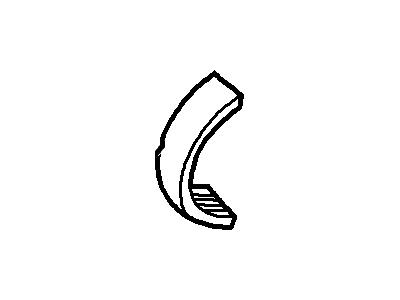

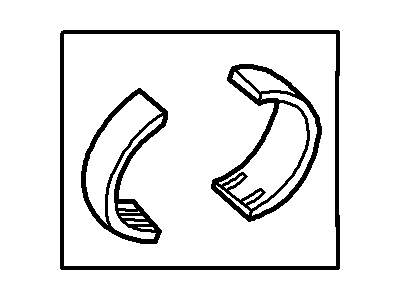

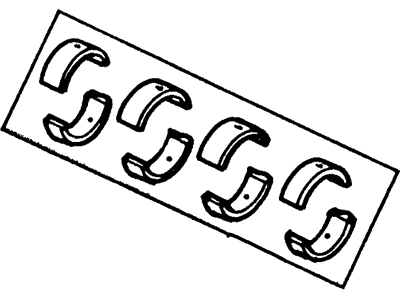

Genuine Ford Ranger Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

35 Rod Bearings found

Ford Ranger Connecting Rod Bearing

Part Number: 6L2Z-6211-C$14.54 MSRP: $20.72You Save: $6.18 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: 6L2Z-6211-D$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business DayFord Ranger Connecting Rod Bearing

Part Number: F8DZ-6211-AA$12.88 MSRP: $19.25You Save: $6.37 (34%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: 6M8Z-6211-B$7.46 MSRP: $10.64You Save: $3.18 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: 6M8Z-6211-C$7.72 MSRP: $11.00You Save: $3.28 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: EJ7Z-6211-G$11.04 MSRP: $15.73You Save: $4.69 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: EJ7Z-6211-H$10.96 MSRP: $15.62You Save: $4.66 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: EJ7Z-6211-J$11.04 MSRP: $15.73You Save: $4.69 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: 6M8Z-6211-A$7.53 MSRP: $10.73You Save: $3.20 (30%)Ships in 1-3 Business DaysFord Ranger Connecting Rod Bearing

Part Number: D2RY-6211-C$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business DayFord Ranger Connecting Rod Bearing

Part Number: XL2Z-6211-FA$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business Day

| Page 1 of 2 |Next >

1-20 of 35 Results

Ford Ranger Rod Bearing

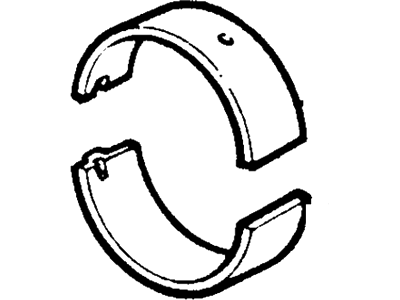

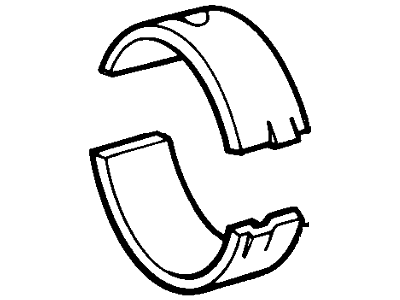

The Rod Bearing used in the Ford Ranger cars is needed for the support of crank shaft and the connecting rods that provides a rotation in the car and reduce friction. These bearings are mainly of plain bearing type and may be of bi-metal or tri-metal construction. Bi-metal Rod Bearings possess a base of aluminum alloy that is sometimes enriched with silicone for improvement of its hardness and seizure coefficient. Tri-metal Rod Bearings on the other hand integrated features such as a copper alloy layer which is coated with a lead-tin-copper overlay which enhance strength and fatigue properties. Over the years, the Ford Ranger Rod Bearings have gone through improvements and thus the high-performance rangers have come with the tri-metal bearings that employ superior materials and finishes to cut on the friction and also offer great strength. Specific design modifications are used in these performance Rod Bearings to keep up high output engines while keeping on with conventional engine oil clearance. They are important because they are part of the Engine and any neglect in installation or maintenance may lead to shortenage of the life span of the Engine.

We provide a wide range of Ford Ranger Rod Bearing at the best prices possible. If you need Ford Ranger Rod Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Ranger Rod Bearing Parts Questions & Experts Answers

- Q: What should be considered when replacing main and connecting rod bearings during an engine overhaul on 1993-2011 Ford Ranger?A:Another procedure which requires changing the main and connecting rod bearings for new ones is the engine overhaul, but the old bearings must be kept as well since they can reveal much information about the state of the engine. Since bearing failure can be attributed to many causes such as inadequate lubrication, foreign particles, excessive loads and corrosion, one has to ensure these causes are erased before the next cycle of use of the bearings by the need to reassemble them. When inspecting the bearings they should be placed out from where they are used and arranged to be clean in order to match any typical flaws with the crankshaft journal. Bearing contaminants may be introduced at assembly or through the filters, and from the machining operation may be partially embedded into the bearing, while larger ones may score the journal. To avoid such failures, cleaning of all the parts and periodic replacing of the oil and filter should be done. Such consequences may arise from insufficient supply of lubricant due to causes such as excessive temperature, excessive loading, loss of oil or obstructions to oil flow and can cause matters such as total removal of the bearing material. Other driving activity also affects bearing or oil, for example, when low RPM is engaged at low speed, this puts crazy loads that force out oil, or alternatively, very short duration trips that do not produce enough heat ending up in corrosion. Also, bearings can fail due to inadequate application of the oil through installation or other surfaces creating high spots.

Related Ford Ranger Parts

Browse by Year

2023 Rod Bearing 2022 Rod Bearing 2021 Rod Bearing 2020 Rod Bearing 2019 Rod Bearing 2011 Rod Bearing 2010 Rod Bearing 2009 Rod Bearing 2008 Rod Bearing 2007 Rod Bearing 2006 Rod Bearing 2005 Rod Bearing 2004 Rod Bearing 2003 Rod Bearing 2002 Rod Bearing 2001 Rod Bearing 2000 Rod Bearing 1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing 1986 Rod Bearing 1985 Rod Bearing 1984 Rod Bearing 1983 Rod Bearing