My Garage

My Account

Cart

Genuine Ford Ranger Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

37 Axle Shafts found

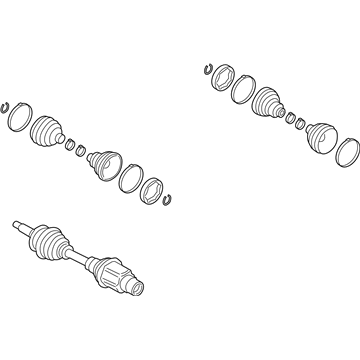

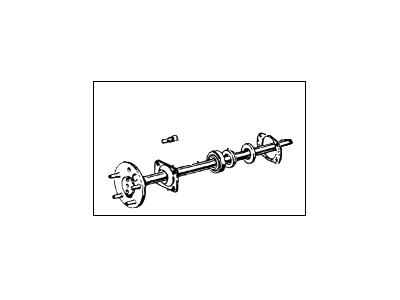

Ford Ranger Front Axle Shaft

Part Number: KB3Z-3A427-D$284.08 MSRP: $464.00You Save: $179.92 (39%)Ships in 1-3 Business DaysFord Ranger Front Axle Shaft

Part Number: 6L5Z-3A427-AA$167.20 MSRP: $276.36You Save: $109.16 (40%)Ships in 1-2 Business DaysFord Ranger Front Axle Shaft

Part Number: 2L2Z-3B437-AA$167.20 MSRP: $276.36You Save: $109.16 (40%)Ships in 1-2 Business DaysFord Ranger Rear Axle Shaft Assembly

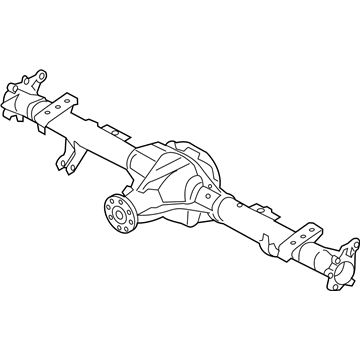

Part Number: KB3Z-4234-C$505.11 MSRP: $745.00You Save: $239.89 (33%)Ships in 1-3 Business Days

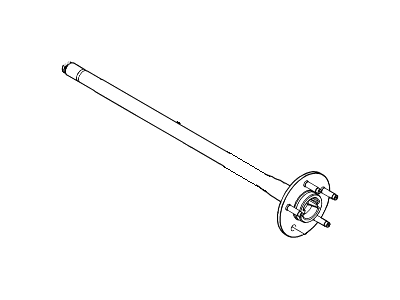

Ford Ranger Front Axle Shaft

Part Number: KB3Z-3A428-E$171.73 MSRP: $278.18You Save: $106.45 (39%)Ships in 1-3 Business DaysFord Ranger Rear Axle Shaft Assembly

Part Number: KB3Z-4234-A$259.90 MSRP: $383.33You Save: $123.43 (33%)

Ford Ranger Front Axle Shaft

Part Number: KB3Z-3A428-B$340.08 MSRP: $567.27You Save: $227.19 (41%)Ships in 1-3 Business DaysFord Ranger Shaft

Part Number: F87Z-4234-BA$282.64 MSRP: $456.50You Save: $173.86 (39%)Ships in 1-2 Business DaysFord Ranger Rear Axle Shaft Assembly

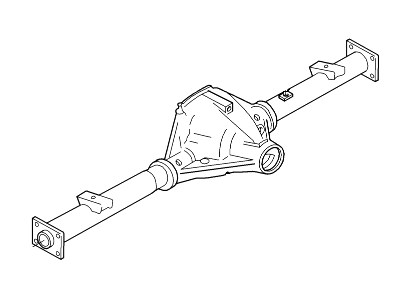

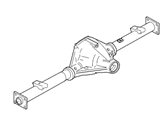

Part Number: KB3Z-4234-D$259.90 MSRP: $383.33You Save: $123.43 (33%)Ford Ranger Rear Axle Housing

Part Number: KB3Z-4010-B$1094.69 MSRP: $1673.83You Save: $579.14 (35%)Ships in 1-3 Business DaysFord Ranger Rear Axle Shaft Assembly

Part Number: KB3Z-4234-B$505.90 MSRP: $746.17You Save: $240.27 (33%)Ford Ranger Rear Axle Shaft Assembly

Part Number: E3TZ-4234-C$176.80 MSRP: $245.60You Save: $68.80 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 37 Results

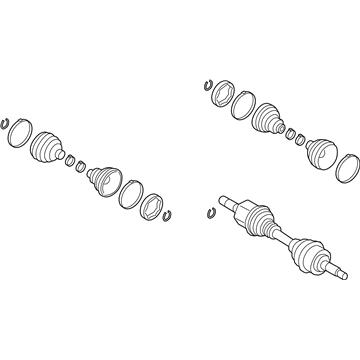

Ford Ranger Axle Shaft

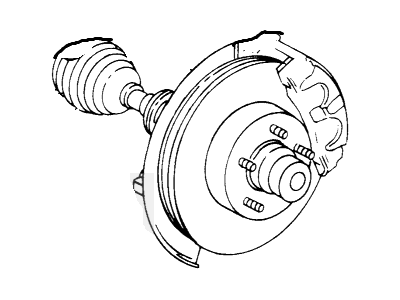

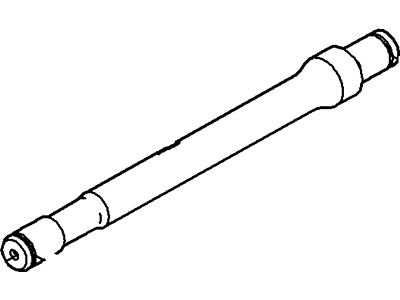

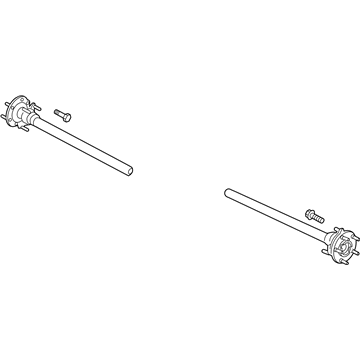

The Axle Shaft is an important component of Ford Ranger vehicles which is responsible for the transmission of power from the differential to the drive wheels that allows for independent rotation of the wheels in order to enhance the capability of the vehicle to stick to the ground during cornering. The Ford Ranger models have both the solid axles and half shafts as a part of their driveshaft assembly based on the suspension system installed. The solid axles are mostly seen in the older models of vehicles and help in providing strength and also in the transfer of torque while half shafts are used in the vehicles which have independent suspension system and connects the transaxle to the wheel. Through the years, the Ford Ranger has used a number of Axle Shafts: live axles for weight and power transfer and split axles for better riding comfort. The distinguishing factor between these two types is in the design as well as in their functionality; the solid axles are more rigid thus suitable for use in vehicles that are to experience heavy usage while the halfshafts are flexible as well as able to offer a smoother ride. In conclusion, it can be said that the Axle Shaft plays a crucial role in providing better performance and handling of the Ford Ranger.

We provide a wide range of Ford Ranger Axle Shaft at the best prices possible. If you need Ford Ranger Axle Shaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Ranger Axle Shaft Parts Questions & Experts Answers

- Q: What is the function and structure of the rear axle assembly, and what are the common issues and diagnostic procedures associated with it on 2000-2011 Ford Ranger?A:The rear axle assembly is a hypoid semi-floating type, featuring a differential carrier made from casting with a pressed steel cover, while the axle tubes are constructed from steel, pressed and welded into the carrier. An optional Traction-Lok limited slip rear axle is available, which operates normally until one wheel loses traction, utilizing multi-disc clutch packs and a speed-sensitive engagement mechanism to lock both axleshafts together, providing equal rotational power to both wheels. Knowing the axle identification number, located on a small metal tag near one of the cover bolts, is crucial for certain operations, especially when replacing the axleshafts. Often, issues suspected in the rear axle area may actually originate elsewhere, so a thorough check is advisable before concluding a rear axle problem. Common noises associated with rear axle diagnosis include road noise, which can be mistaken for mechanical faults and remains consistent regardless of vehicle power; tire noise, which can arise from worn or under-inflated tires and remains constant during various driving conditions; and engine and transmission noise, which can mislead diagnostics as it travels along the driveline. To isolate such noises, noting the engine speed at which the noise is most pronounced and then running the engine in Neutral at the same speed can help determine if the rear axle is at fault. Overhaul and general repair of the rear axle require special tools and critical measurements, making it beyond the scope of the home mechanic, with procedures involving axleshaft removal and installation, oil seal replacement, bearing replacement, and complete unit removal for repair or replacement.

Related Ford Ranger Parts

Browse by Year

2023 Axle Shaft 2022 Axle Shaft 2021 Axle Shaft 2020 Axle Shaft 2019 Axle Shaft 2011 Axle Shaft 2010 Axle Shaft 2009 Axle Shaft 2008 Axle Shaft 2007 Axle Shaft 2006 Axle Shaft 2005 Axle Shaft 2004 Axle Shaft 2003 Axle Shaft 2002 Axle Shaft 2001 Axle Shaft 2000 Axle Shaft 1999 Axle Shaft 1998 Axle Shaft 1989 Axle Shaft 1988 Axle Shaft 1987 Axle Shaft 1986 Axle Shaft 1985 Axle Shaft 1984 Axle Shaft 1983 Axle Shaft