My Garage

My Account

Cart

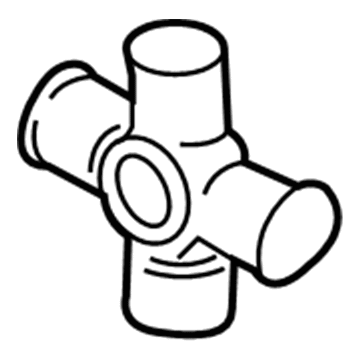

Genuine Ford Mustang Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Universal Joints found

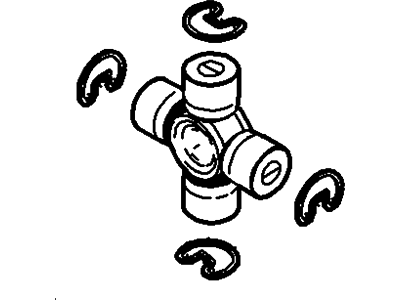

Ford Mustang Universal Joint Repair Kit

Part Number: 7L1Z-4635-B$46.63 MSRP: $60.67You Save: $14.04 (24%)Ford Mustang Universal Joint Repair Kit

Part Number: FL3Z-4635-B$46.28 MSRP: $66.50You Save: $20.22 (31%)Ships in 1-2 Business DaysFord Mustang U-Joint Repair Kit

Part Number: FL3Z-4635-A$46.28 MSRP: $66.50You Save: $20.22 (31%)Ships in 1-2 Business DaysFord Mustang U-Joint Kit

Part Number: F5TZ-4635-A$42.22 MSRP: $60.67You Save: $18.45 (31%)Ships in 1-2 Business DaysFord Mustang U-Joint Repair Kit

Part Number: F2AZ-4635-C$33.35 MSRP: $47.50You Save: $14.15 (30%)Ships in 1-2 Business DaysFord Mustang U-Joint Repair Kit

Part Number: F2AZ-4635-A$42.13 MSRP: $61.60You Save: $19.47 (32%)Ships in 1-3 Business DaysFord Mustang KIT - UNIVERSAL JOINT REPAIR

Part Number: ML3Z-4635-AA$155.50 MSRP: $227.33You Save: $71.83 (32%)Ships in 1-2 Business Days

Ford Mustang Universal Joint

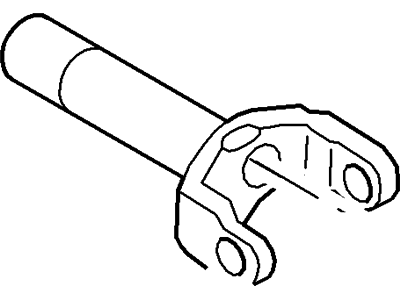

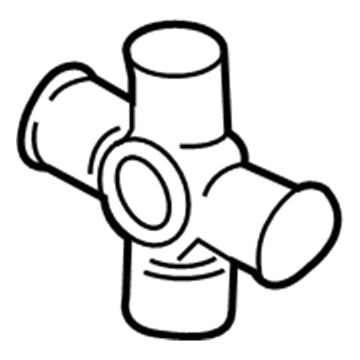

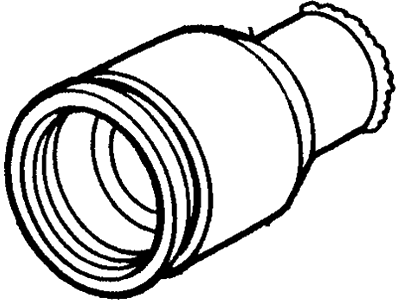

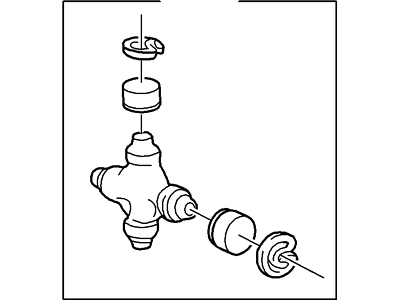

The inevitable movement coupled by the suspension leads to the need of Universal Joint in Ford Mustang cars to link the driveshaft to the differential. This one allows the driveshaft to rotate so as to allow changes in the angles, usually between its transmission and differential. In most cases, Ford Mustang incorporates a Universal Joint at the Transmissions slip yoke as well as at the rear end of the driveshaft at the differential yoke or flange. Features of this Universal Joint are, It is made of hardened steel cups that contain cross and needle bearings. Factory Universal Joints are supplied with lubricant while the ones may include a grease zerk for re-greasing. There have been several Universal Joint style used in the Ford Mustang models over the years and the differences have only been in the type of lubrication offered as well as the possibility of servicing the Universal Joints or not. Our research shows that as Worn Universal Joints causes noticeable problems which include clunking noises and vibrations, so as to fix the above problems it is necessary to regularly inspect and replace the Worn Universal Joints to enhance vehicle performance as required.

We provide a wide range of Ford Mustang Universal Joint at the best prices possible. If you need Ford Mustang Universal Joint, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Universal Joint Parts Questions & Experts Answers

- Q: How to replace a universal joint in a driveshaft on Ford Mustang?A:A press or large vise will be called for in this procedure and unless you have special access to heavy duty equipment, it may be well to take the driveshaft to a local dealer service department, service station or machinist if a universal joint is broken, generally at a moderate cost. Procedures start by eliminating the driveshaft. When the U-joints have external snap-rings, it is necessary to take out the snap-rings from the spider by means of a small pair of pliers. Place support blocks under the Drive Shaft and set the same on a flat working platform fitted with a vise. You can take a piece of pipe or a big socket where the inside diameter is a little greater than the outside diameter of the bearing cap; then align on it a socket of an outside diameter a little less than the outside diameter of the other bearing cap. Push the bearing cap out as far as you are able, use a vise or press and then use the vise or large pliers to finish it out. Slide the sockets to the other side and similar to the above process, push the bearing cap out. Apply grease to the new universal joint bearings and do it according to the instructions in the servicing kit that were given. Place the spider into the yoke and screw in one bearing cap to halfway, then turn the spider to start it into the second bearing cap and screw that in also to halfway. Synchronise the spider and fix the bearing caps in place but do not risk deforming the dust seals in the process. Fit the snap-rings, and if there is a problem in gripping, then use a hammer to strike on the driveshaft yoke to help the snap-rings to settle in the groove. Many a time, the joint is overfilled with grease when installing the grease fitting and this can blow out the grease seals. Finally, install the driveshaft.

Related Ford Mustang Parts

Browse by Year

2024 Universal Joint 2023 Universal Joint 2022 Universal Joint 2021 Universal Joint 2020 Universal Joint 2019 Universal Joint 2018 Universal Joint 2017 Universal Joint 2016 Universal Joint 2015 Universal Joint 2014 Universal Joint 2013 Universal Joint 2012 Universal Joint 2011 Universal Joint 2010 Universal Joint 2009 Universal Joint 2008 Universal Joint 2007 Universal Joint 2006 Universal Joint 2005 Universal Joint 2004 Universal Joint 2003 Universal Joint 2002 Universal Joint 2001 Universal Joint 2000 Universal Joint 1999 Universal Joint 1998 Universal Joint 1997 Universal Joint 1996 Universal Joint 1995 Universal Joint 1994 Universal Joint 1993 Universal Joint 1992 Universal Joint 1991 Universal Joint 1990 Universal Joint 1989 Universal Joint 1988 Universal Joint 1987 Universal Joint 1986 Universal Joint 1985 Universal Joint 1984 Universal Joint 1983 Universal Joint 1982 Universal Joint 1981 Universal Joint 1980 Universal Joint