My Garage

My Account

Cart

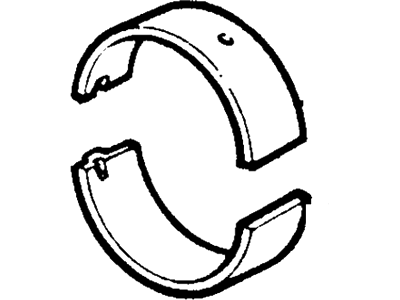

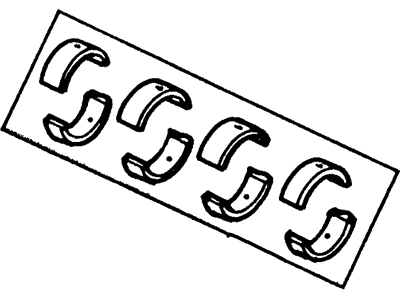

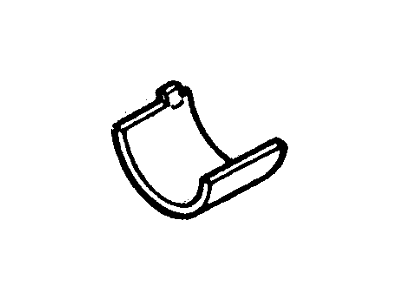

Genuine Ford F-250 Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Rod Bearings found

Ford F-250 Connecting Rod Bearing

Part Number: 1C3Z-6211-AA$49.56 MSRP: $73.86You Save: $24.30 (33%)Ships in 1-2 Business DaysFord F-250 Connecting Rod Bearing

Part Number: 5C3Z-6211-AB$4.59 MSRP: $6.53You Save: $1.94 (30%)Ships in 1-3 Business DaysFord F-250 Connecting Rod Bearing

Part Number: F65Z-6211-EA$4.59 MSRP: $6.53You Save: $1.94 (30%)Ships in 1-3 Business DaysFord F-250 Connecting Rod Bearing

Part Number: F4TZ-6211-A$49.56 MSRP: $73.86You Save: $24.30 (33%)Ships in 1-2 Business DaysFord F-250 Connecting Rod Bearing

Part Number: F65Z-6211-FA$19.12 MSRP: $27.23You Save: $8.11 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

Ford F-250 Rod Bearing

In Ford F-250, the particular component called Rod Bearing has important function of bearing the crankshaft and connecting rods meaning that it supports the crankshaft while also reducing its rotation friction. Such bearings are normally plain bearings that can be made from bi-metal or tri-metal. Selflubricating bi-metal Rod bearings use an aluminium base metal with silicone incorporated commonly used for increase in hardness and seizure. On the other hand, those which are classified as tri-metal Rod Bearings is made of layers of copper alloy and lead-tin-copper overlay for added strength and fatigue. Like any other automotive vehicles, different Ford F-250 models through the years have followed different types of Rod Bearing, while those with performance characteristics have seen the use of special materials and coatings that would ultimately prove for dimension and friction. These performance Rod Bearings come with certain specified eccentricities for the purpose of sustaining the oil clearance and can also have enhanced oil holes. Want proper performance of the Rod Bearing on Ford F-250, it is highly advisable to ensure that the installation details of the Rod Bearing and the clearance measurement are well adopted.

We provide a wide range of Ford F-250 Rod Bearing at the best prices possible. If you need Ford F-250 Rod Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford F-250 Rod Bearing Parts Questions & Experts Answers

- Q: What should be done with old bearings during an engine overhaul, and why is it important to examine them on Ford F-250?A:When doing an engine overhaul it is common to remove the main and connecting rod bearings and replace them with new ones while the old ones are used for analysis. Some of the causes of bearing failure include; inadequate lubrication, dirt accumulation, overloading, and corrosion, any one of which has to be treated before reassembling the engine, otherwise, it will recur. On the latter, bearings should be taken out of their positions and arranged on a flat surface to align any defects that may be on the crankshaft journal. Contaminants may be introduced to the engine during: assembly, filter, PCV system and; often may be metal chips and abrasives that are used during machining or reconditioning of the engine. Larger Foreign Particles can get lodged in the bearing material surface, and huge particles may cause scoring or gouging of the bearing material surface. That is why proper washing of all components and oil and filter replacement are so important in order to avoid such failures. Where no lubricant is available the reasons may include: high temperatures, overloading, leakage of oil, blocked oil supplies,where bearing metal is removed and the backing gets to overheat. Common traversing behaviors are also very influential in bearing duration; for example, low-speed racing generates high loads that expel the oil while short excursions are eradicative because the heat cannot expunge moisture and gases. Also, when bearings are wrongly positioned, it can lead to oil starvation or there tends to be formation of high spots which lead to failure.

Related Ford F-250 Parts

Browse by Year

1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing 1986 Rod Bearing 1985 Rod Bearing 1984 Rod Bearing 1983 Rod Bearing 1982 Rod Bearing 1981 Rod Bearing 1980 Rod Bearing