My Garage

My Account

Cart

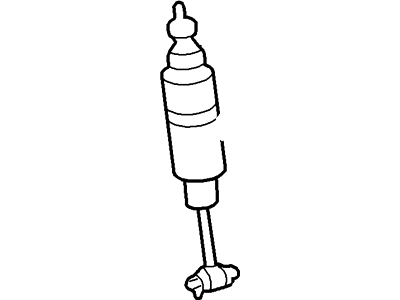

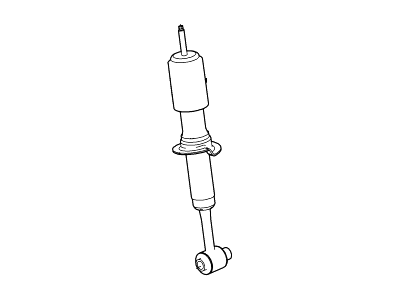

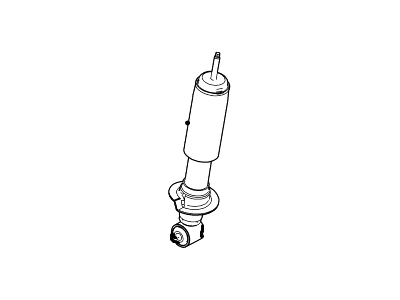

Genuine Ford Explorer Sport Trac Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Shock Absorbers found

Ford Explorer Sport Trac Shock Absorber Kit

Part Number: 5U2Z-18V124-MA$51.73 MSRP: $87.09You Save: $35.36 (41%)Ford Explorer Sport Trac Shock Absorber Assembly

Part Number: 1L5Z-18125-AA$54.97 MSRP: $92.55You Save: $37.58 (41%)Ships in 1-2 Business DaysFord Explorer Sport Trac Shock Absorber Assembly

Part Number: 1L5Z-18125-KA$54.97 MSRP: $92.55You Save: $37.58 (41%)Ford Explorer Sport Trac Shock Absorber Assembly

Part Number: 4L2Z-18125-DA$54.97 MSRP: $92.55You Save: $37.58 (41%)

| Page 1 of 2 |Next >

1-20 of 21 Results

Ford Explorer Sport Trac Shock Absorber

The Shock Absorber in Ford Explorer Sport Trac is an important part of the vehicle's suspension system, which aims at reducing the bouncing effect and providing comfortable riding experience. via hydraulic actions of the shock absorber, kinetic energy is transformed into heat to counteract the force of shock impulses thus provides better handling on loose surfaces. Since the manufacturing of the Ford Explorer Sport Trac, the manufacturers incorporate the following Shock Absorbers, Twin Tube and Mono Tube. Twin-tube shocks are quite often used and the design of the shock that can be either a twin-tube or a straight-tube is relatively uncomplicated and can be gas charged. On the other hand, mono-tube shocks provide a better heat exchange and also performance, with capability of being mounted in various installation patterns. Some of the high end features include the Position Sensitive Damping (PSD) as well as the Acceleration Sensitive Damping (ASD) to further enhance the driving experience of the Ford Explorer Sport Trac and the improvement of its suspension system.

We provide a wide range of Ford Explorer Sport Trac Shock Absorber at the best prices possible. If you need Ford Explorer Sport Trac Shock Absorber, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Sport Trac Shock Absorber Parts Questions & Experts Answers

- Q: How to inspect and remove front shock absorbers on Ford Explorer Sport Trac?A:There even is a simple test to determine the effectiveness of shock damping, vigorously shake the ends of the vehicle until it stops bouncing after you release it; one to two slight rebounds and then settling are normal, excessive bouncing means that the shocks need to be changed. If the shock absorbers pass this test then there is a check of the shock body to look for weeping or damage, or deep denting, if any damaged or weeping shock absorbers need to be changed even if they passed the bounce test. Once the shock absorber has been changed, the piston rod should be pulled out and pushed back in a number of times in order to be sure that it was working smoothly; if there are some slews in the piston movement-you should replace the shock absorber immediately. Automobile shock absorbers should be pumped fully in and out several times before fitting new shock absorbers with piston rod to wet the seals and hydraulic sections. Warning is given that low pressure gas shock absorbers are charged with nitrogen gas typically to 135 PSI and should not be opened punctured or exposed to heat. The lug nuts on the side of the front wheel to be dismantled should be loosened, the car then raised and well supported on jack stands and the front wheel should be detached. For vehicles equipped with Automatic Ride Control (ARC) the depressing air suspension switch shall be switched off prior to actuating the air suspension switch, to avoid damage. The electrical connectors of the shocks and the airline should be disconnected, the airline can be removed by pinching the plastic ring and pulling the airline out. The upper nut can be loosened by use of deep socket accompanied by use of open-end wrench to hold the shaft, lifting or unscrewing the washer. Regarding ARC systems, the height sensor at the front left should be detached from the upper bracket; the bolt and, depending on the model, the nut through which the shock absorber is fixed to the radius arm for the 1991-1994 models, nuts at the lower Control Arm for the 1995 models and thereafter. The shock absorber is to be slightly compressed in order to fully detach it from the major brackets. The process of installation is the reverse of that of removal and during the process new nuts and bolts should be use and the nuts tighten to the right torque in order to install the wheel and use the lug nuts to lower the vehicle while tightening the lug nuts in the proper torque.