My Garage

My Account

Cart

Genuine Ford Excursion Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Headlights found

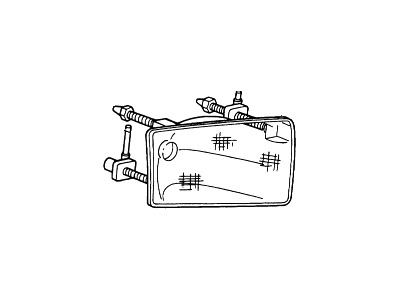

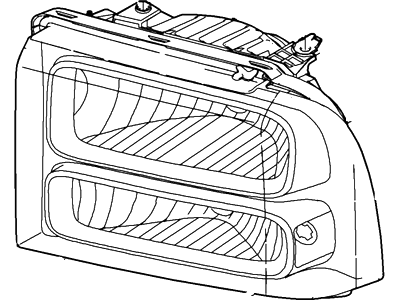

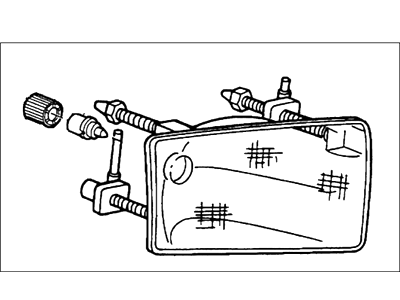

Ford Excursion Headlamp Assembly

Part Number: XC3Z-13008-BA$59.90 MSRP: $87.57You Save: $27.67 (32%)Ships in 1-2 Business DaysFord Excursion Headlamp Assembly

Part Number: XC3Z-13008-AA$66.31 MSRP: $96.95You Save: $30.64 (32%)Ships in 1-2 Business DaysFord Excursion Headlamp Assembly

Part Number: 1C3Z-13008-BA$59.90 MSRP: $87.57You Save: $27.67 (32%)

Ford Excursion Headlight

The Headlight of Ford Excursion models performs two vital functions which provide lighting for ahead traffic and enhance night driving safety by illuminating the path as well as giving visibility to approaching cars. The present-day composite Headlight combine advanced form and reduced air drag to embed turn signals together with parking lights and running lights into the Headlight's structure. Through time Ford Excursion Headlight have introduced three different types of illumination systems which include halogen Headlight alongside LED illumination and xenon (HID) lighting solutions. Halogen Headlight remain the leading choice because of their budget-friendly cost but supply users with a shorter lamp duration. The many current models use LED replacement units because they deliver both extended operating duration and energy-saving capabilities and xenon Ford Excursion replacement parts operate without metal filaments while giving off a distinct blue light. The selection of lights among vehicle owners depends on the combination of brightness capabilities and material longevity which each light source provides.

We provide a wide range of Ford Excursion Headlight at the best prices possible. If you need Ford Excursion Headlight, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Excursion Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure safety and visibility on Ford Excursion?A:The headlights need to be aligned in the correct manner to avoid blinding other road users; an act, which, may cause accidents of high severity, or hinder vision. The aim should be checked at least yearly or when either a new headlight is fitted or when there is some front-end body work. Some vehicles have adjustment screws at the top of the halogen bulb style headlights; for sealed beam headlights there are in board and upper adjustment screws only externally visible. One of the most basic ways of making the adjustment is with the help of masking-tape, 'blank' wall and 'level ' floor. Taping work should begin at the desired position on the wall and was fixed to draw a vertical line corresponding to a center line of the vehicle when used with the center line of both headlights, as well as a horizontal tape line. The vehicle must be parked 25 feet from the wall, not tilted, containing half a tank capacity of gasoline and should not be carrying any overloading. For low beam adjustment position the high-intensity zone 2 inches under a horizontal line drawn through the centre of the headlamp and 2 inches to the side of a vertical line drawn through the centre of the motor vehicle away from traffic moving in the opposite direction, and then tighten the screws. With the high beam on the high intensity zone should ideally be just below the horizontal line at night. If you have to negotiate, retain low beams on the grounds of safety and then seek to get the headlights calibrated by a professional as soon as possible.