My Garage

My Account

Cart

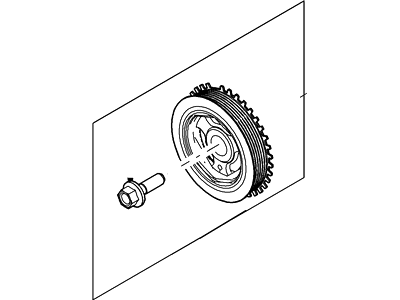

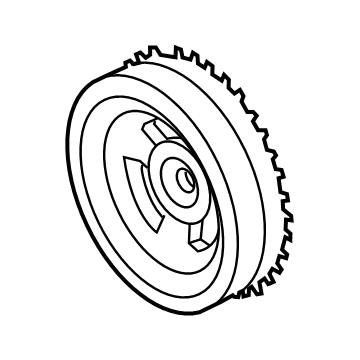

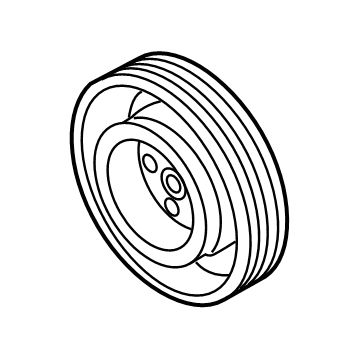

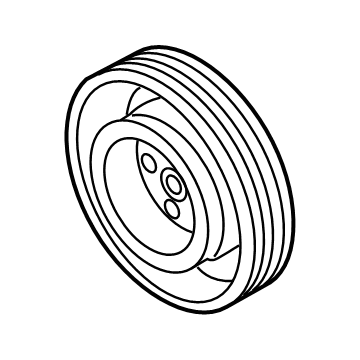

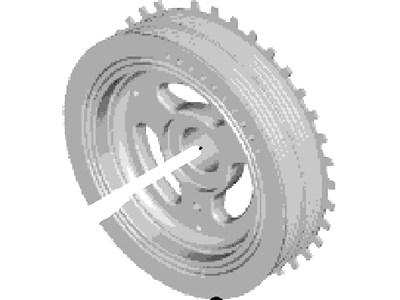

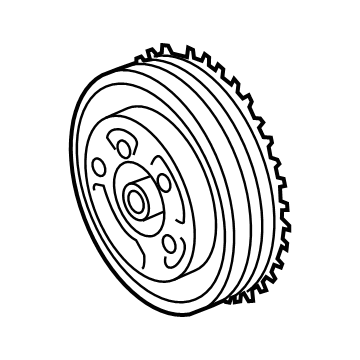

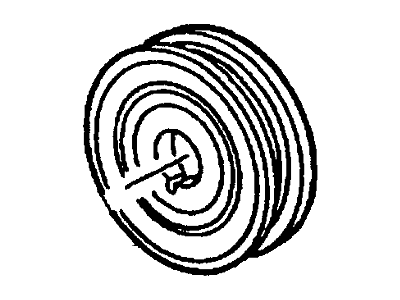

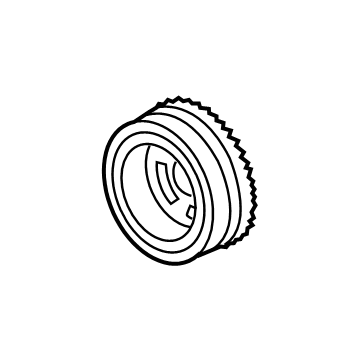

Genuine Ford Escape Crankshaft Pulley

Crankshaft Pulley Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Crankshaft Pulleys found

Ford Escape Damper Pulley

Part Number: 6E5Z-6312-AA$319.68 MSRP: $493.33You Save: $173.65 (36%)Ships in 1-2 Business DaysFord Escape Damper Assembly

Part Number: F7RZ-6316-AA$334.48 MSRP: $493.33You Save: $158.85 (33%)Ships in 1-2 Business DaysFord Escape Crankshaft Pulley

Part Number: BM5Z-6312-A$231.84 MSRP: $345.00You Save: $113.16 (33%)Ships in 1-3 Business DaysFord Escape Crankshaft Pulley

Part Number: 9E5Z-6312-B$102.45 MSRP: $149.78You Save: $47.33 (32%)Ships in 1-3 Business DaysFord Escape Crankshaft Pulley

Part Number: 7U7Z-6312-A$181.26 MSRP: $265.00You Save: $83.74 (32%)Ships in 1-2 Business DaysFord Escape PULLEY - CRANKSHAFT

Part Number: LX6Z-6312-A$103.58 MSRP: $151.43You Save: $47.85 (32%)Ships in 1-2 Business DaysFord Escape Crankshaft Pulley

Part Number: CJ5Z-6312-C$135.66 MSRP: $198.33You Save: $62.67 (32%)Ships in 1-3 Business DaysFord Escape PULLEY - CRANKSHAFT

Part Number: PV4Z-6312-A$73.61 MSRP: $107.62You Save: $34.01 (32%)Ships in 1-2 Business DaysFord Escape Crankshaft Pulley

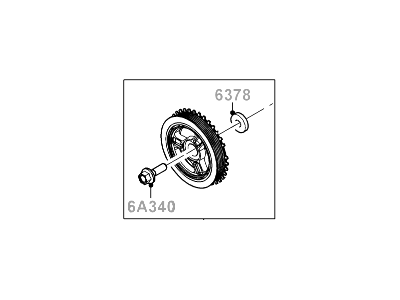

Part Number: HX7Z-6B321-A$91.42 MSRP: $133.65You Save: $42.23 (32%)Ships in 1-3 Business DaysFord Escape Crankshaft Pulley

Part Number: CV6Z-6312-C$103.96 MSRP: $151.98You Save: $48.02 (32%)Ships in 1-3 Business DaysFord Escape PULLEY - CRANKSHAFT

Part Number: P2GZ-6312-A$120.13 MSRP: $175.63You Save: $55.50 (32%)Ships in 1-2 Business Days

Ford Escape Crankshaft Pulley

The Performance Crankshaft Pulley on Ford Escape vehicles plays a very important role of transferring power from the crankshaft to other components including the power steering pump, A/C and the alternator. This part directly coupling with the engine crankshaft, the Performance Crankshaft Pulley offers an efficient torque transmission in addition to dampening the vibrations making it also called the harmonic balance wheel. There are different types of Performance Crankshaft Pulley that have been used in different Ford Escape model and these are meant to improve the performance of the car. These pulleys may be of different types, designs, and construction material and this affects their efficiency in power distribution and vibration control. Thus, the changes in the Performance Crankshaft Pulley are one of the improvements in engineering directed at enhancing the general performance of Ford Escape.

We provide a wide range of Ford Escape Crankshaft Pulley at the best prices possible. If you need Ford Escape Crankshaft Pulley, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Escape Crankshaft Pulley Parts Questions & Experts Answers

- Q: How to remove and install the crankshaft pulley in four cylinder engine on Ford Escape?A:To disassemble it, one has to first retrieve the drive belt to expose the crankshaft pulley from the 2.0L engine. If the pulley is incorporated in another process like the timing belt change procedure fix the engine at TDC before removing the crankshaft bolt for pulley removal While loosening the bolt to remove the crankshaft pulley do not use the timing pin to lock the crankshaft as it may shear off. To avoid turning of the crankshaft during the process of loosening of the pulley bolt, pull it to a halt in this manner; If you are using a chain wrench ensure that it has some protective covering, or else you can lock the Flywheel using a screwdriver. Following the removal of pulley bolt, take off the pulley. For installation, reverse the above procedures and arrange the pulley keyway on the crankshaft with the locating key and tighten the pulley bolt to the recommended torque. For the 2.3L and 2.5L engines, the timing belt will come off as soon as the crankshaft pulley is loosened; thus, use the following instructions when assembling to prevent serious damage. First eliminate the cooling fan and shroud, auxiliary drive belt, and the valve cover; position the engine to the TDC. Make sure that the camshaft alignment plate and crankshaft alignment bolt are fitted right. There is a particular tool for holding the crankshaft pulley to prevent damage when trying to loosen the pulley bolt. Before tightening the new crankshaft pulley, give the crankshaft front seal a light coating of oil after you have taken out the pulley. Tighten a new pulley bolt by hand and place it near the timing chain cover, fasten a crankshaft pulley alignment bolt just in case to provide proper alignment. Screw the pulley bolt to the said torque and then take out the holding tool as well as the alignment bolt. Place the engine at the 'T' mark and provide 2 full clockwise revolutions before setting the engine at the 'T' mark and installing the timing pin. In case of any doubt reposition the crankshaft pulley and ensure that you use the camshaft tool to determine the correct position of the camshaft so that other tools can be placed correctly for timing. Last but not the least; unbolt all the timing pin and tools, fix the timing pin plug back and just reverse the process you have just done.

Related Ford Escape Parts

Browse by Year

2023 Crankshaft Pulley 2022 Crankshaft Pulley 2021 Crankshaft Pulley 2020 Crankshaft Pulley 2019 Crankshaft Pulley 2018 Crankshaft Pulley 2017 Crankshaft Pulley 2016 Crankshaft Pulley 2015 Crankshaft Pulley 2014 Crankshaft Pulley 2013 Crankshaft Pulley 2012 Crankshaft Pulley 2011 Crankshaft Pulley 2010 Crankshaft Pulley 2009 Crankshaft Pulley 2008 Crankshaft Pulley 2007 Crankshaft Pulley 2006 Crankshaft Pulley 2005 Crankshaft Pulley 2004 Crankshaft Pulley 2003 Crankshaft Pulley 2002 Crankshaft Pulley 2001 Crankshaft Pulley