My Garage

My Account

Cart

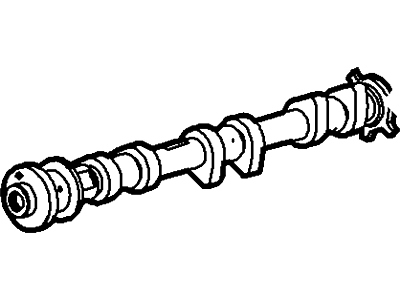

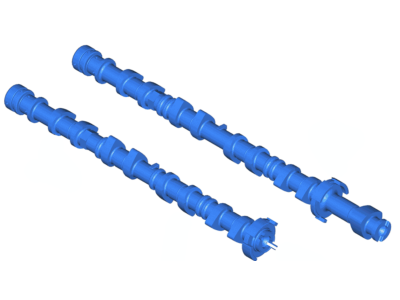

Genuine Lincoln MKX Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Camshafts found

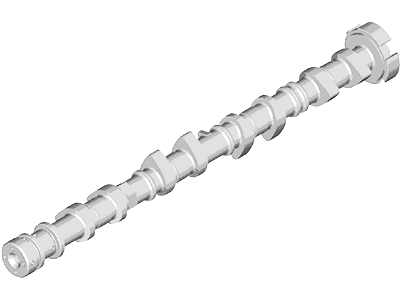

Lincoln MKX Camshaft

Part Number: BB5Z-6250-A$66.71 MSRP: $97.53You Save: $30.82 (32%)Ships in 1-3 Business DaysLincoln MKX Camshaft

Part Number: FT4Z-6250-C$134.81 MSRP: $209.00You Save: $74.19 (36%)Ships in 1-3 Business DaysLincoln MKX Camshaft

Part Number: FT4Z-6250-B$98.66 MSRP: $152.53You Save: $53.87 (36%)Ships in 1-3 Business DaysLincoln MKX Camshaft

Part Number: 9T4Z-6250-A$89.80 MSRP: $124.74You Save: $34.94 (29%)Ships in 1-2 Business DaysLincoln MKX Camshaft

Part Number: 7T4Z-6250-D$179.32 MSRP: $262.17You Save: $82.85 (32%)Ships in 1-3 Business DaysLincoln MKX Camshaft

Part Number: FT4Z-6250-D$92.08 MSRP: $139.52You Save: $47.44 (34%)Ships in 1-2 Business DaysLincoln MKX Camshaft

Part Number: AT4Z-6250-D$111.98 MSRP: $163.72You Save: $51.74 (32%)Ships in 1-3 Business Days

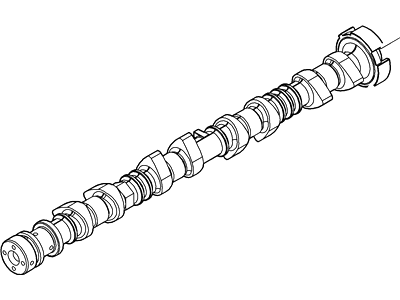

Lincoln MKX Camshaft

Camshaft located in Lincoln MKX vehicle helps in controlling the opening and closing of intake and exhaust valves for letting in of the air/fuel mixture and outflow of exhaust gases respectively. Dominantly made of iron or steel, the Lincoln MKX camshaft works through the following designs, Over Head Valve (OHV), Single Over Head Cam (SOHC) and Double Over Head Cam (DOHC). All these affect the engine performance uniquely, DOHC arrangement enables a precise control of both intake as well as exhaust valves. The Lincoln MKX has its camshaft driven by the crankshaft to maintain the correct timing of the valves to enhance the functioning of the engine. There exists the possibility of achieving performance variability through the intake camshafts since these are normally available in the with higher lift and longer durations that would result in increased airflow as well as power. Other important features like Lobe Separation Angle (LSA) which influences torque and idle definitely offers different driving feel in response to certain requirements.

We provide a wide range of Lincoln MKX Camshaft at the best prices possible. If you need Lincoln MKX Camshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln MKX Camshaft Parts Questions & Experts Answers

- Q: What should be checked before removing the camshafts for a procedure in four cylinder engine on Lincoln MKX?A:If the camshafts have to be removed for any procedure, it is better to check the valve clearances prior to disassembly in order to order new lifters, if needed, from a dealership. Start with the Timing Chain removal-pay attention to the shape of the cam lobes of the no. 1 cylinder and slots in the ends of the camshafts. Disassemble the camshaft phaser and the sprockets that accompanies it with the help of an Allen wrench, and mark the parts that are to be reattached, with indelible ink. While holding the cam shaft in position, suspend the camshaft sprocket bolt just as much as necessary to allow loosening. Secondly there is need to, unsurprisingly, remove the Variable Camshaft Timing (VCT) solenoid fasteners and the front camshaft bearing cap bolts which lifts the cap off the two camshafts. Identify and indicate the bearing caps so that the right ones will be placed back in the correct position and with the correct orientation. Some of the camshaft bearing cap bolts may be extremely tight due to the pressure of the valve springs; as such, they can be removed progressively while loosening the tension of the springs, then remove the caps and take out the camshafts, noting that the exhaust camshaft has a reference lobe. It is important only to store each of the lifters in a clean container without swapping any of them. Look for worn out camshafts and lifters, check on the diameters of the lifters, and also look for signs of damages. If the engine contains loud noise at the valve components, setting the valve clearances could be called for. ScrollView the camshaft lobes and bearings for flatness and wear and measure the diameters of the journal. Measuring the bearing journal running clearance by Plastigage and if any clearance is beyond the service means, replace the camshaft or Cylinder Head. To get an indicator mark, clean those bearing surfaces and then to measure the camshaft endplay use a dial indicator. When installing ensure that the crankshaft is at the T DC; oil the lifter bores and the lifters and then place them back in their positions. Lubricate the camshaft bearing surfaces and then fit camshafts are to be in proper alignment. Remove all the dirt on the surfaces that are to be mated this is followed by application of RTV sealant on to the exhaust camshaft rear bearing cap. Place the camshaft bearing caps as indicated by the marked positions and then fasten them in the manner that was described above. Last, attach the variable camshaft timing solenoids, the phasers, the sprockets after which follows the reassembly of the timing chain, phaser and the re-timing of the valves, before fitting the valve cover the valve clearances should also be checked.