My Garage

My Account

Cart

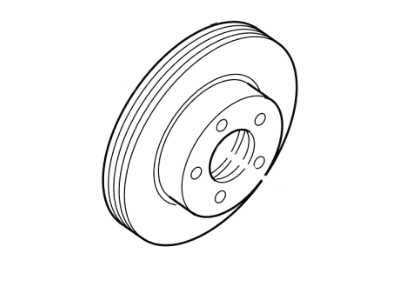

Genuine Ford Ranger Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Brake Discs found

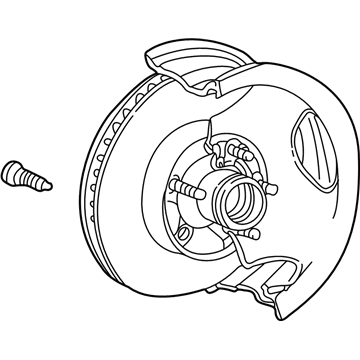

Ford Ranger Hub Assembly - Wheel

Part Number: 4L5Z-1102-BA$79.79 MSRP: $116.65You Save: $36.86 (32%)Ford Ranger Rotor Assembly

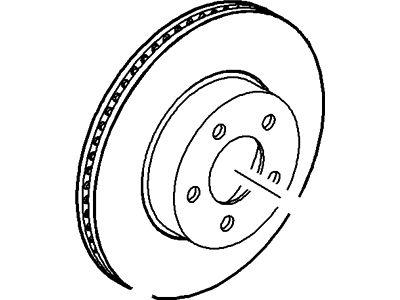

Part Number: 3L5Z-1125-AA$86.23 MSRP: $133.32You Save: $47.09 (36%)Ships in 1 Business DayFord Ranger Hub And Disc Assembly

Part Number: YL5Z-1V102-EA$75.45 MSRP: $116.65You Save: $41.20 (36%)Ford Ranger Hub And Disc Assembly

Part Number: YL5Z-1V102-FA$75.45 MSRP: $116.65You Save: $41.20 (36%)Ford Ranger Rotor Assembly

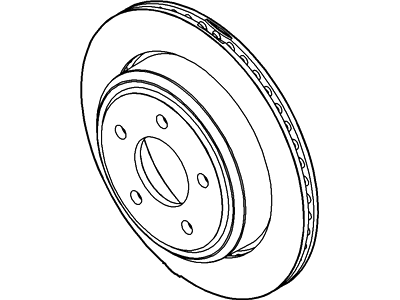

Part Number: 2U2Z-1V125-FA$74.54 MSRP: $116.65You Save: $42.11 (37%)Ships in 1 Business DayFord Ranger Brake Rotor Assembly

Part Number: AL5Z-2C026-A$86.23 MSRP: $133.32You Save: $47.09 (36%)Ships in 1 Business DayFord Ranger Brake Rotor Assembly

Part Number: KB3Z-1125-A$109.78 MSRP: $166.33You Save: $56.55 (34%)Ships in 1-3 Business DaysFord Ranger Hub And Disc Assembly

Part Number: YL2Z-1V102-AA$64.03 MSRP: $87.48You Save: $23.45 (27%)Ford Ranger Brake Rotor Assembly

Part Number: KB3Z-2C026-B$87.99 MSRP: $133.32You Save: $45.33 (34%)Ships in 1-3 Business DaysFord Ranger Hub And Disc Assembly

Part Number: YL2Z-1V102-CA$76.99 MSRP: $116.65You Save: $39.66 (34%)Ford Ranger Hub And Disc Assembly

Part Number: YL5Z-1V102-BA$64.03 MSRP: $87.48You Save: $23.45 (27%)Ford Ranger Hub And Disc Assembly

Part Number: G2MZ-1V102-LA$38.32 MSRP: $52.36You Save: $14.04 (27%)Ford Ranger Hub And Disc Assembly

Part Number: YL5Z-1V102-AA$36.59 MSRP: $49.99You Save: $13.40 (27%)

| Page 1 of 2 |Next >

1-20 of 22 Results

Ford Ranger Brake Disc

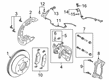

The Brake Disc is an integral part of the disc brake system in Ford Ranger Trucks where it gets to exert the required friction on the disc to enable the stopping power of the truck when the brake pedal is pressed. These rotors are usually created from gray iron although they can be made from other types of metals, some of them have features like fins or vanes that help in cooling since cooling is vital in sustaining the efficiency of the brake system. Different models of Brake Disc have been used in Ford Ranger for years now, and such types include the drilled and the slotted types that provide proper space for heat clearance and Brake Disc noise. Such weight and thermal optimized features are the use of two-piece rotors the includes a separable center section and a friction ring. It is also important to have periodic checks on the Brake Disc because it may sometimes warp, crack or rust which will affect its capability to provide the needed braking force. Regular check-ups on the brake system and replacement of pads to exactly the right time can enable customers to keep on trusting Ford Ranger.

We provide a wide range of Ford Ranger Brake Disc at the best prices possible. If you need Ford Ranger Brake Disc, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Ranger Brake Disc Parts Questions & Experts Answers

- Q: How to remove and install Brake Disc on 2000-2011 Ford Ranger?A:To access front and rear disc brake assemblies, remove the wheel lug nuts, then raise then support the car on jackstands and subsequently remove the wheel. Further on, to release the disc for access lift off the brake caliper without disconnecting the brake hose and secure this part provising the hose in loop wire, do not twist this hose. Looking the disc surface for score marks and damage; minor grooves are normally present but deep score marks that are in excess of 0.015 inch will require disc removal and refinishing by an automotive machine shop. Check the top and bottom of the disc and if pulsating occur during this braking assume disc runout. For runout control, on a disc, fix a dial indicator about half an inch of from the outer edge and rotate it, the zero pistol should not exceed the allowable limit of runout; if it does, refinish the disc. If can want a smooth flat disc to avoid brake pedal pulsations then it is recommended to resurface brake discs and if not then de-glaze the surfaces by rubbing with emery cloth or sandpaper in circular or swirling fashion. Make sure that the disc has not been machined below the minimum refinish thickness that is embossed on the inside of the disc and is measured with a micrometer at three or four positions one half inch from the edge. If it is tight to remove the disc from the hub then place a wooden block on the rotor and give light blow through the hammer so that the disc become free from the stickiness. For installation the steps are to reverse the removal process and fix the caliper, followed by the wheel with the nuts tightened. Bring the vehicle down to the ground then apply handbrakes, further tighten the lugs nuts to the required torque then pedal the brake several time so that the Brake Pads make contact with the disc. Bleeding is only needed if the brake hose was disconnected from the caliper; to make sure the brakes are working properly before returning to normal use.

Related Ford Ranger Parts

Browse by Year

2023 Brake Disc 2022 Brake Disc 2021 Brake Disc 2020 Brake Disc 2019 Brake Disc 2011 Brake Disc 2010 Brake Disc 2009 Brake Disc 2008 Brake Disc 2007 Brake Disc 2006 Brake Disc 2005 Brake Disc 2004 Brake Disc 2003 Brake Disc 2002 Brake Disc 2001 Brake Disc 2000 Brake Disc 1999 Brake Disc 1998 Brake Disc 1997 Brake Disc 1996 Brake Disc 1995 Brake Disc 1994 Brake Disc 1993 Brake Disc 1992 Brake Disc 1991 Brake Disc 1990 Brake Disc