My Garage

My Account

Cart

Genuine Ford Mustang Oxygen Sensors

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

65 Oxygen Sensors found

Ford Mustang Exhaust Gas Oxygen Sensor

Part Number: FR3Z-9G444-A$48.30 MSRP: $68.55You Save: $20.25 (30%)Ships in 1 Business DayFord Mustang Exhaust Gas Oxygen Sensor

Part Number: JR3Z-9G444-C$60.98 MSRP: $100.80You Save: $39.82 (40%)Ships in 1-3 Business DaysFord Mustang Sensor - Hego

Part Number: 8F9Z-9F472-H$96.25 MSRP: $159.09You Save: $62.84 (40%)Ships in 1 Business DayFord Mustang Sensor - Hego

Part Number: BL3Z-9F472-A$133.10 MSRP: $220.00You Save: $86.90 (40%)Ships in 1-2 Business DaysFord Mustang Sensor - Hego

Part Number: FB5Z-9F472-A$66.08 MSRP: $111.45You Save: $45.37 (41%)Ships in 1 Business DayFord Mustang Sensor - Hego

Part Number: FR3Z-9F472-A$101.42 MSRP: $167.64You Save: $66.22 (40%)Ships in 1 Business DayFord Mustang Exhaust Gas Oxygen Sensor

Part Number: FL3Z-9G444-A$56.16 MSRP: $94.55You Save: $38.39 (41%)Ships in 1 Business DayFord Mustang Sensor - Hego

Part Number: FL3Z-9F472-A$58.85 MSRP: $97.27You Save: $38.42 (40%)Ships in 1 Business DayFord Mustang Exhaust Gas Oxygen Sensor

Part Number: FL3Z-9G444-C$77.44 MSRP: $128.00You Save: $50.56 (40%)Ships in 1 Business DayFord Mustang Exhaust Gas Oxygen Sensor

Part Number: BR3Z-9G444-A$73.70 MSRP: $121.82You Save: $48.12 (40%)Ships in 1-2 Business DaysFord Mustang Sensor - Hego

Part Number: 9E5Z-9F472-D$107.03 MSRP: $176.91You Save: $69.88 (40%)Ships in 1-2 Business DaysFord Mustang Sensor - Hego

Part Number: 8F9Z-9F472-D$132.00 MSRP: $218.18You Save: $86.18 (40%)Ships in 1 Business DayFord Mustang Sensor - Hego

Part Number: 5C5Z-9F472-AA$55.77 MSRP: $92.18You Save: $36.41 (40%)Ships in 1 Business DayFord Mustang Sensor - Hego

Part Number: XC2Z-9F472-AA$55.77 MSRP: $92.18You Save: $36.41 (40%)Ships in 1 Business DayFord Mustang Exhaust Gas Oxygen Sensor

Part Number: FL3Z-9G444-B$53.02 MSRP: $87.64You Save: $34.62 (40%)Ford Mustang Sensor - Hego

Part Number: FR3Z-9F472-E$55.55 MSRP: $91.82You Save: $36.27 (40%)Ships in 1-2 Business DaysFord Mustang Exhaust Gas Oxygen Sensor

Part Number: ML3Z-9G444-A$113.19 MSRP: $190.91You Save: $77.72 (41%)Ships in 1-2 Business DaysFord Mustang Sensor - Hego

Part Number: F4ZZ-9F472-B$70.46 MSRP: $96.27You Save: $25.81 (27%)Ships in 1-2 Business Days

| Page 1 of 4 |Next >

1-20 of 65 Results

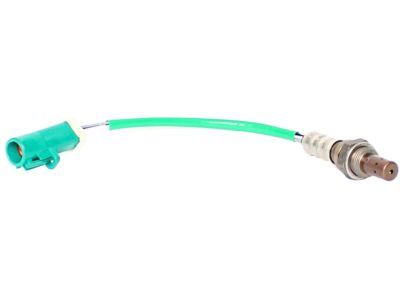

Ford Mustang Oxygen Sensors

Oxygen Sensors is an important component of Ford Mustang car model, that is responsible for analyzing the amount of the unburned oxygen in the exhaust that is vital to adjust the air fuel mixture ratio and reduction of emissions. Since voltage signal is proportional to the concentration of oxygen, the sensor feedbacks the engine control computer to adjust the fuel injector pulse width for effective combustion. Depending on the model of Ford Mustang, different types of Oxygen Sensorss were and are being used, including mainly zirconia Oxygen Sensors which can be divided into narrow-band and wide-band systems. The narrow-band sensors supply only signal for narrow or cone air-fuel mixture, drawing whereas the wide-band sensors supply signal for wide or elliptical air-fuel mixture. The fundamental difference must be sought in mechanisms of work, where wideband sensors offer better data for fuel accounting. As these sensors wear out or when they are contaminated, their efficiency is affected thus contributing to high emissions and in the case of Ford Mustang vehicles reduced fuel efficiency.

We provide a wide range of Ford Mustang Oxygen Sensors at the best prices possible. If you need Ford Mustang Oxygen Sensors, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Oxygen Sensors Parts Questions & Experts Answers

- Q: What general information should be considered when servicing an oxygen sensor on Ford Mustang?A:When servicing an oxygen sensor, special care is essential due to the permanently attached pigtail and electrical connector that cannot be removed; any damage or removal will ruin the sensor. It is important to keep grease, dirt, and other contaminants away from the electrical connector and the louvered end of the sensor, and cleaning solvents should never be used on an oxygen sensor or air/fuel ratio sensor. Avoid dropping or roughly handling the sensor, and ensure the silicone boot is installed correctly to prevent melting and ensure proper operation. Since oxygen sensors are located in the exhaust system, which contracts when cool, they may be difficult to loosen when the engine is cold; starting the engine for a minute or two can help. Begin by disconnecting the cable from the negative terminal of the battery and securely raising the vehicle on jackstands. There are two upstream oxygen sensors on all models, with specific locations depending on the engine type. Locate the desired upstream oxygen sensor, trace the lead to the electrical connector, and disconnect it before using a special oxygen sensor socket to unscrew the sensor. Clean the threads of the sensor bore in the exhaust manifold after removing the old sensor. If reinstalling the old sensor, apply anti-seize compound to the threads; for a new sensor, this is unnecessary as they come pre-coated. Installation follows the reverse order of removal, ensuring the sensor is tightened to the specified torque. For downstream oxygen sensors, which are also present in pairs, disconnect the electrical connector before unscrewing and removing the sensor. Clean the threads of the sensor bore in the Catalytic Converter, apply anti-seize compound if reinstalling the old sensor, and remember that new sensors do not require this. Again, installation is the reverse of removal, with attention to proper torque during tightening.

Related Ford Mustang Parts

Browse by Year

2024 Oxygen Sensors 2023 Oxygen Sensors 2022 Oxygen Sensors 2021 Oxygen Sensors 2020 Oxygen Sensors 2019 Oxygen Sensors 2018 Oxygen Sensors 2017 Oxygen Sensors 2016 Oxygen Sensors 2015 Oxygen Sensors 2014 Oxygen Sensors 2013 Oxygen Sensors 2012 Oxygen Sensors 2011 Oxygen Sensors 2010 Oxygen Sensors 2009 Oxygen Sensors 2008 Oxygen Sensors 2007 Oxygen Sensors 2006 Oxygen Sensors 2005 Oxygen Sensors 2004 Oxygen Sensors 2003 Oxygen Sensors 2002 Oxygen Sensors 2001 Oxygen Sensors 2000 Oxygen Sensors 1999 Oxygen Sensors 1998 Oxygen Sensors 1997 Oxygen Sensors 1996 Oxygen Sensors 1995 Oxygen Sensors 1994 Oxygen Sensors 1993 Oxygen Sensors 1992 Oxygen Sensors 1991 Oxygen Sensors 1990 Oxygen Sensors