My Garage

My Account

Cart

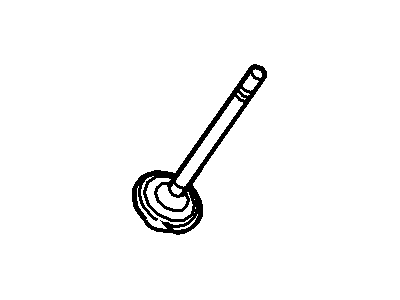

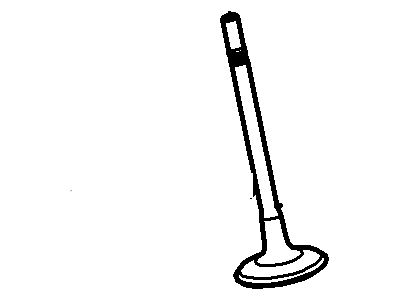

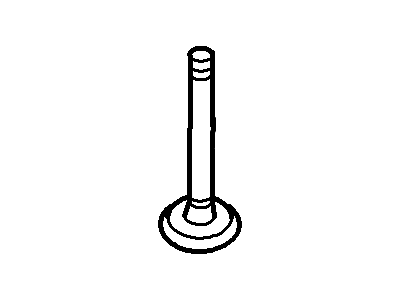

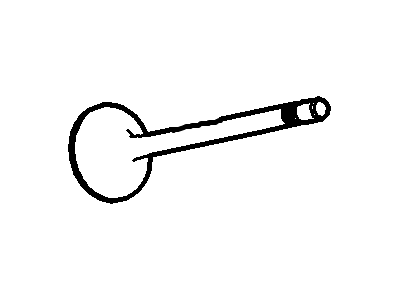

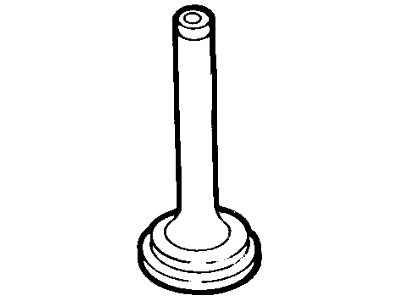

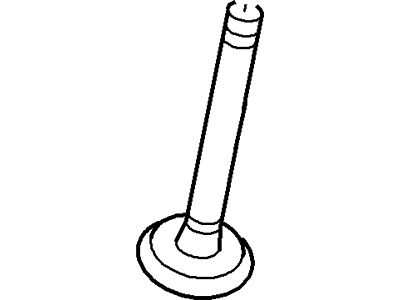

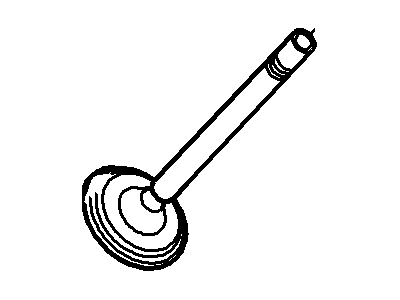

Genuine Ford Mustang Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Exhaust Valves found

Ford Mustang Exhaust Valve

Part Number: 4C3Z-6505-A$69.60 MSRP: $101.75You Save: $32.15 (32%)Ships in 1-2 Business DaysFord Mustang Exhaust Valve

Part Number: 4C3Z-6505-AA$69.60 MSRP: $101.75You Save: $32.15 (32%)Ships in 1-2 Business DaysFord Mustang Exhaust Valve

Part Number: EJ7Z-6505-A$25.58 MSRP: $37.40You Save: $11.82 (32%)Ships in 1-2 Business DaysFord Mustang Exhaust Valve

Part Number: BR3Z-6505-A$13.54 MSRP: $19.62You Save: $6.08 (31%)Ships in 1-3 Business DaysFord Mustang Exhaust Valve

Part Number: FR3Z-6505-A$21.49 MSRP: $30.62You Save: $9.13 (30%)Ships in 1-3 Business DaysFord Mustang Exhaust Valve

Part Number: 4G7Z-6505-AA$83.27 MSRP: $121.73You Save: $38.46 (32%)Ships in 1-3 Business DaysFord Mustang Exhaust Valve

Part Number: CR3Z-6505-A$34.56 MSRP: $48.01You Save: $13.45 (29%)Ships in 1-2 Business DaysFord Mustang Valve Exhaust

Part Number: E9SZ6505A$18.13 MSRP: $24.77You Save: $6.64 (27%)Ships in 1-2 Business DaysFord Mustang Exhaust Valve

Part Number: F6ZZ-6505-A$79.69 MSRP: $116.50You Save: $36.81 (32%)Ships in 1-3 Business DaysFord Mustang Exhaust Valve

Part Number: GR3Z-6505-A$35.35 MSRP: $53.17You Save: $17.82 (34%)Ships in 1-3 Business DaysFord Mustang Exhaust Valve

Part Number: GR3Z-6505-B$35.35 MSRP: $53.17You Save: $17.82 (34%)Ships in 1-3 Business DaysFord Mustang Exhaust Valve

Part Number: F3LY-6505-A$30.54 MSRP: $43.50You Save: $12.96 (30%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 25 Results

Ford Mustang Exhaust Valve

Exhaust Valve in the Ford Mustang vehicles is useful for the internal combustion engine because it helps in the releasing of burnt exhaust gases from its cylinders. This process is very important especially in maintaining the performance of the engine because any problem with the Exhaust Valve can lead to problems like, low power, misfires, rough idle, poor fuel economy. Different kinds of Exhaust Valves have been used in Ford Mustang over the years, and every of them was meant to optimize the quality of the car's engine. While specific styles may differ, the primary function remains consistent: in order to allow the smooth expulsion of exhaust gases without hassle whatsoever. It is essential to understand the working principles and the kinds of Exhaust Valves applied in Ford Mustang vehicles to prolong their service life as well as their efficient functioning.

We provide a wide range of Ford Mustang Exhaust Valve at the best prices possible. If you need Ford Mustang Exhaust Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Exhaust Valve Parts Questions & Experts Answers

- Q: How to check and adjust valve clearances after replace camshafts or valve-related parts on Ford Mustang?A:It is important to check the valve clearances with the help of a cold engine. It is recommended that the valve clearances be checked and altered only after the Camshaft(s) or any other related valve parts have been replaced, or when there is much rumbling noise in the valve-train. Start from disconnecting the cable that is connected to the negative terminal of the battery next is remove the spark plugs and the valve covers. Position the engine with the Crankshaft Pulley center bolt on the cylinder to be checked until cam lobes are out of the lifters as possible using socket and breaker bar. Gauge the clearance of each valve with a feeler gauge of the specified thickness; slight drag on the feeler gauge will tell that the clearance is correct. Record any valve which is out of specification as this will form part of the analysis when estimating the number of required replacement lifters. Again we shall repeat the same process for all the valves. Any of the clearance that exist must be adjusted by replacing the lifter with a new lifter whose thickness head is of a different measure. Stoke the lifters to be replaced and record their assorted valves. Head thickness of each lifter is to be measured using the micrometer on the center projection on the underside for accuracy. To calculate the correct thickness for a replacement lifter that will achieve the specified valve clearance, use the formula: A new lifter thickness would therefore be calculated as: N equal R + (M1-M2) These lifters are stamped on the bottom to show their size such a code 3.310 means the thickness is 3.31mm or 0.13 inch. This lifters are then marked according to their installation location, then applied with engine assembly lube and finally installed. To rectify the problem replace the lifters, reset the camshafts and Timing Chains and after that adjust the valve clearances.

Related Ford Mustang Parts

Browse by Year

2023 Exhaust Valve 2022 Exhaust Valve 2021 Exhaust Valve 2020 Exhaust Valve 2019 Exhaust Valve 2018 Exhaust Valve 2017 Exhaust Valve 2016 Exhaust Valve 2015 Exhaust Valve 2014 Exhaust Valve 2013 Exhaust Valve 2012 Exhaust Valve 2011 Exhaust Valve 2010 Exhaust Valve 2009 Exhaust Valve 2008 Exhaust Valve 2007 Exhaust Valve 2006 Exhaust Valve 2005 Exhaust Valve 2004 Exhaust Valve 2003 Exhaust Valve 2002 Exhaust Valve 2001 Exhaust Valve 2000 Exhaust Valve 1999 Exhaust Valve 1998 Exhaust Valve 1997 Exhaust Valve 1996 Exhaust Valve 1995 Exhaust Valve 1994 Exhaust Valve 1993 Exhaust Valve 1992 Exhaust Valve 1991 Exhaust Valve 1990 Exhaust Valve 1989 Exhaust Valve 1988 Exhaust Valve 1987 Exhaust Valve 1986 Exhaust Valve 1985 Exhaust Valve 1984 Exhaust Valve 1983 Exhaust Valve 1982 Exhaust Valve 1981 Exhaust Valve 1980 Exhaust Valve