My Garage

My Account

Cart

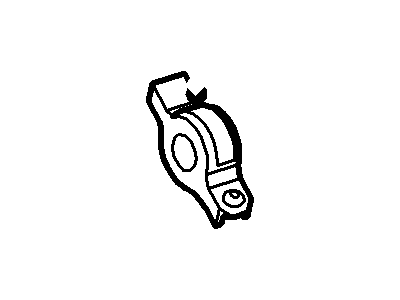

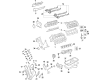

Genuine Ford Mustang Rocker Arm

Engine Rocker Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Rocker Arms found

Ford Mustang Valve Rocker Arm Assembly

Part Number: E9SZ-6564-A$23.33 MSRP: $31.87You Save: $8.54 (27%)Ships in 1-2 Business DaysFord Mustang Valve Rocker Arm Assembly

Part Number: E43Z-6564-A$13.73 MSRP: $18.75You Save: $5.02 (27%)Ships in 1-2 Business DaysFord Mustang Valve Rocker Arm Assembly

Part Number: E1FZ-6564-A$16.25 MSRP: $22.20You Save: $5.95 (27%)Ford Mustang Valve Rocker Arm Assembly

Part Number: F8AZ-6564-AA$22.21 MSRP: $32.47You Save: $10.26 (32%)Ships in 1 Business DayFord Mustang Valve Rocker Arm Assembly

Part Number: YL2Z-6564-AA$20.82 MSRP: $30.43You Save: $9.61 (32%)Ford Mustang Valve Rocker Arm Assembly

Part Number: 4G7Z-6564-AA$30.10 MSRP: $44.00You Save: $13.90 (32%)Ships in 1-2 Business DaysFord Mustang Valve Rocker Arm Assembly

Part Number: F6AZ-6564-AA$22.21 MSRP: $32.47You Save: $10.26 (32%)Ships in 1 Business DayFord Mustang Valve Rocker Arm Assembly

Part Number: 3L3Z-6564-BA$23.37 MSRP: $34.17You Save: $10.80 (32%)Ships in 1 Business DayFord Mustang Valve Rocker Arm Assembly

Part Number: BR3Z-6564-A$18.81 MSRP: $27.50You Save: $8.69 (32%)Ships in 1-2 Business Days

Ford Mustang ARM ASY - VALVE ROCKER

Part Number: ML3Z-6564-A$17.32 MSRP: $24.67You Save: $7.35 (30%)Ships in 1-2 Business DaysFord Mustang Valve Rocker Arm Assembly

Part Number: EOAZ-6564-B$16.30 MSRP: $23.83You Save: $7.53 (32%)Ships in 1-3 Business DaysFord Mustang Valve Rocker Arm Assembly

Part Number: F2AZ-6564-A$22.21 MSRP: $32.47You Save: $10.26 (32%)Ships in 1 Business DayFord Mustang Valve Rocker Arm Assembly

Part Number: GR3Z-6564-BA$30.42 MSRP: $45.47You Save: $15.05 (34%)Ford Mustang Valve Rocker Arm Assembly

Part Number: GR3Z-6564-A$30.42 MSRP: $45.47You Save: $15.05 (34%)Ford Mustang Valve Rocker Arm Assembly

Part Number: HL3Z-6564-D$29.60 MSRP: $42.17You Save: $12.57 (30%)Ships in 1-3 Business Days

Ford Mustang Rocker Arm

Ford Mustang automobiles have the Rocker Arm as part of the valvetrain system whose primary function is to relay motion from the pushrod to the intake and the exhaust valves. Usually made of stamped steel or aluminum, the Rocker Arm changes the attitude of the pushrod and applies the required amount of force to the valves. In high RPM applications aluminum is more common for its lightweight nature whereas cast iron or forged carbon steel is more common in diesel engines. Various types of Rocker Arms, as the roller rockers incorporate needle bearings intending to decrease friction and general wear as opposed to a conventional Rocker Arm design. The rocker ratio is found in today's Ford Mustang engines with varying between 1.5:1 and 1.8:1, amplifies the camshaft lift to increase performance. The revised fulcrum bearings are also used to handle stresses and prolong durability in high RPM Mustangs, another evolution of the Rocker Arm in these legendary vehicles.

We provide a wide range of Ford Mustang Rocker Arm at the best prices possible. If you need Ford Mustang Rocker Arm, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Rocker Arm Parts Questions & Experts Answers

- Q: What are the methods for removing rocker arms and lash adjusters in V6 engine on Ford Mustang?A:There are two techniques of dismantling the rocker arms and lash adjusters of this engine however the manufacturer prefers the technique that allows removal of the rocker arms and lash adjusters together without having to remove the Camshaft(s) and this they can be done by using the special valve spring compressor meant for the engine. This proceeds from the camshaft, and accompanied with a ratchet or a breaker bar, it depresses the valve spring so that tension on the rocker arm is removed. The other method of its measurement entails the withdrawal of the camshaft for measurements to be made on it. First, remove the valve cover(s) and place the valve spring compressor tool in position and compress the spring only to take the rocker arm loose. Before proceeding the camshaft rocker arms and hydraulic lash adjusters have to be refitted in the positions they were removed from, so do not forget to label all the parts before storing them. Subsequently, disconnect the hydraulic lash adjuster and make sure you set aside things that will need to be reassemble. If the vehicle has very high trip settings, the adjusters might be built to last longer and rather stubborn to come out; use of penetrating oil will be helpful. Visual check each adjuster for wear and possible damage, such as pitting or discoloration, and consider to replace it in case doubts concerning it or in case of existence of the noise in the valve train are presupposed. An ordinary hair-pin or a twig of a paperclip can be used to touch the plunger to feel whether it has a restricted movement of not more than 1.5mm. Recommended for adjustment when one of the carriers requires replacement, it is better to replace the entire set and then avoid using more cash for repair. Also be sure also to check the conditions of the rocker arms by applying pressure to them to see signs of wear or damage. Prior to the installation of the lash adjusters, purge them of air as follows: stand the lash adjusters vertically in the oil and with the help of a thin wire or paper clip work the plunger. Coat the tip of stem, the rocker arm, the lash adjuster bore with clean engine oil; place the lash adjusters and the rocker arms with the aid of compressed valve spring. This is a process of removal and hence the steps followed here are the reverse of the steps that were highlighted during installation process. Modified lash adjusters will make some noise when starting until the air is cleared off; to reduce the noise on start up, change the engine speed from idle position to 3,000 rpm for one minute after the engine is warm.

Related Ford Mustang Parts

Browse by Year

2023 Rocker Arm 2022 Rocker Arm 2021 Rocker Arm 2020 Rocker Arm 2019 Rocker Arm 2018 Rocker Arm 2017 Rocker Arm 2016 Rocker Arm 2015 Rocker Arm 2014 Rocker Arm 2013 Rocker Arm 2012 Rocker Arm 2011 Rocker Arm 2010 Rocker Arm 2009 Rocker Arm 2008 Rocker Arm 2007 Rocker Arm 2006 Rocker Arm 2005 Rocker Arm 2004 Rocker Arm 2003 Rocker Arm 2002 Rocker Arm 2001 Rocker Arm 2000 Rocker Arm 1999 Rocker Arm 1998 Rocker Arm 1997 Rocker Arm 1996 Rocker Arm 1995 Rocker Arm 1994 Rocker Arm 1993 Rocker Arm 1992 Rocker Arm 1991 Rocker Arm 1990 Rocker Arm 1989 Rocker Arm 1988 Rocker Arm 1987 Rocker Arm 1986 Rocker Arm 1985 Rocker Arm 1984 Rocker Arm 1983 Rocker Arm 1982 Rocker Arm 1981 Rocker Arm 1980 Rocker Arm