My Garage

My Account

Cart

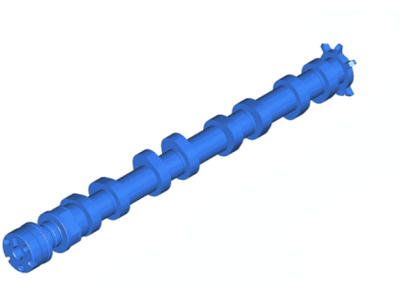

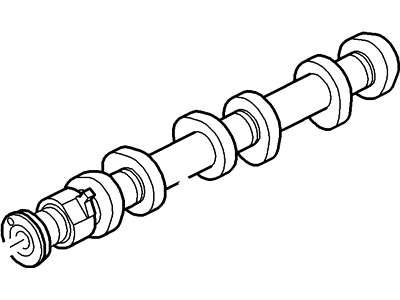

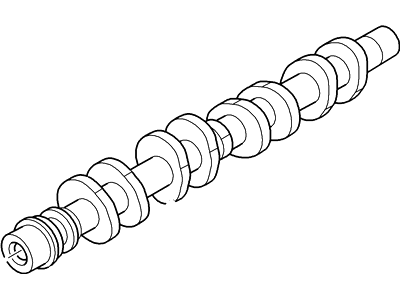

Genuine Ford Mustang Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

59 Camshafts found

Ford Mustang Camshaft

Part Number: BR3Z-6250-F$731.81 MSRP: $1089.00You Save: $357.19 (33%)Ships in 1-3 Business DaysFord Mustang Camshaft

Part Number: GR3Z-6250-B$191.86 MSRP: $280.50You Save: $88.64 (32%)Ships in 1-2 Business DaysFord Mustang Camshaft

Part Number: 5L1Z-6250-AA$185.59 MSRP: $271.33You Save: $85.74 (32%)Ships in 1-3 Business DaysFord Mustang Camshaft

Part Number: BR3Z-6250-E$731.81 MSRP: $1089.00You Save: $357.19 (33%)Ships in 1-3 Business DaysFord Mustang Camshaft

Part Number: FR3Z-6250-C$403.41 MSRP: $595.00You Save: $191.59 (33%)Ships in 1-3 Business DaysFord Mustang Camshaft

Part Number: BR3Z-6250-H$747.82 MSRP: $1112.83You Save: $365.01 (33%)Ships in 1-2 Business DaysFord Mustang Camshaft

Part Number: BB5Z-6250-B$66.71 MSRP: $97.53You Save: $30.82 (32%)Ships in 1-3 Business DaysFord Mustang Camshaft

Part Number: BR3Z-6250-G$749.06 MSRP: $1114.67You Save: $365.61 (33%)Ships in 1-2 Business DaysFord Mustang Camshaft

Part Number: 7L2Z-6250-A$180.58 MSRP: $264.00You Save: $83.42 (32%)Ships in 1-3 Business DaysFord Mustang Camshaft

Part Number: YF3Z-6250-AA$577.89 MSRP: $921.67You Save: $343.78 (38%)Ships in 1-2 Business DaysFord Mustang Camshaft

Part Number: F3LY-6250-C$577.89 MSRP: $921.67You Save: $343.78 (38%)Ships in 1-2 Business DaysFord Mustang Camshaft

Part Number: BR3Z-6250-B$731.81 MSRP: $1089.00You Save: $357.19 (33%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 59 Results

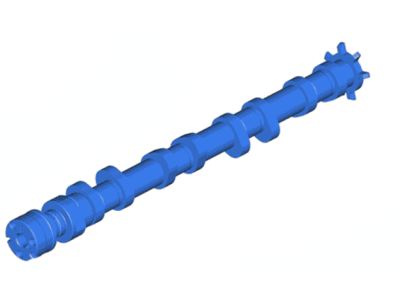

Ford Mustang Camshaft

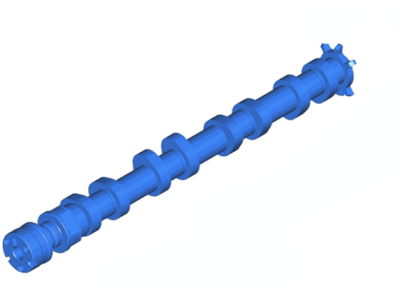

Crucial in the motion of the car, the camshaft of the Ford Mustang is an important part of the car's engine which regulates the timing of the engine and the phases of the cylinder strokes synchronously. This one rotates with the help of a timing belt or a chain and works at a speed half as that of the crankshaft. It contains cams which presses on the intake and exhaust values to open them while the springs help to close them. Different camshaft techniques have also been applied to the Ford Mustang models over time such as the SOHC and DOHC systems depending on the type of engine model and the desired goals and objectives. The material that is often used for making camshafts of the car such as the Ford Mustang includes the cast iron and billet steel where the billet steel is only used here in the high performer and special edition models. When deciding between SOHC and DOHC options in the Ford Mustang, the engine performance varies, and DOHC is known to have more precise control of the valve timing. These accuracies increase power and efficiency in performance, necessary in the high-performance Ford Mustang engines requirement. In general, the camshaft in the Ford Mustang has dimensions and is made of material that should be chosen in order to achieve maximum performance and power from the engine. This is in a bid to reduce mechanical loss on the camshaft and retain the characteristic power that is associated with the ford mustang brand.

We provide a wide range of Ford Mustang Camshaft at the best prices possible. If you need Ford Mustang Camshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Camshaft Parts Questions & Experts Answers

- Q: How to remove and install Camshaft in V6 engine on Ford Mustang?A:It is a very complex structure to work with and in particularly with the Timing Chains, only special tools designed for working on the 3.7L engine will suffice to undertake the task in order not to damage the engine. As an interference engine the timing chain if snapped this can lead to valve and possibly piston damage, it requires Cylinder Head removal. Due to the complexity of the timing system, a slight mistake can cause a lot of damage to the engine, thus, they should only be done by highly qualified personnel, and it is always good to cross check all the repairs done before starting the engine. Two special camshaft holding tools (manufacturer tool no. 303-1248) are required for the operations described). Before camshafts can be taken out, the valve clearance should be checked, at the same time the primary timing chain and camshaft VCT unit is to be taken out. To examine hydraulic lifters, one has to first remove camshaft caps while paying attention to their arrangement; after this, camshafts can be pulled out of the cylinder head. Lifters should be removed with magnet and the same placed in a container marked for assembly after the end of the test. After camshaft removal they should be cleaned and checked for wear or damage before Guage dimensions are taken to determine if they meet their specifications. If one finds the camshaft lobes intact and in good condition then it is possible to reuse them. Proper alignment of the crankshaft before application of lubricants on the lifters and camshafts as well as re-fixing the seals that go well with lifters and camshafts. This is done by tightening the camshaft bearing caps in the correct order and also by further adjustments of the valve clearance. Before going ahead with the VCT units and the primary timing chain, the camshaft holding tools must be fitted. The same is true for the 4.0L engine procedure which is quite elaborate and involves the use of special tools and engine pull out. It entails such tasks as, dismantling involving taking off of valve covers, measuring of camshaft end play, loosening of bearing cap screws, and making sure all parts are replaced in their respective positions. During inspection, horn and camshaft journals and lobes are inspected for signs of wear and when this is done, camshaft journals and lobes are measured in relation to their specified measurements and replaced if not as required. Oil clearance checks are made with the use of Plastigage, and should the clearances be large, then the cylinder head has to be replaced. If any had been taken out, they had to be replaced on the same position and then lubricated before having the camshaft caps tightened to the recommended torque setting.

Related Ford Mustang Parts

Browse by Year

2023 Camshaft 2022 Camshaft 2021 Camshaft 2020 Camshaft 2019 Camshaft 2018 Camshaft 2017 Camshaft 2016 Camshaft 2015 Camshaft 2014 Camshaft 2013 Camshaft 2012 Camshaft 2011 Camshaft 2010 Camshaft 2009 Camshaft 2008 Camshaft 2007 Camshaft 2006 Camshaft 2005 Camshaft 2004 Camshaft 2003 Camshaft 2002 Camshaft 2001 Camshaft 2000 Camshaft 1999 Camshaft 1998 Camshaft 1997 Camshaft 1996 Camshaft 1995 Camshaft 1994 Camshaft