My Garage

My Account

Cart

Genuine Ford Explorer Sport Trac Oxygen Sensors

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Oxygen Sensors found

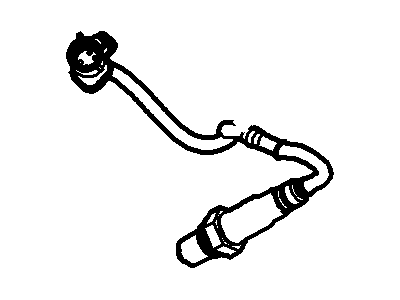

Ford Explorer Sport Trac Sensor - Hego

Part Number: XL3Z-9F472-AA$69.30 MSRP: $114.55You Save: $45.25 (40%)Ford Explorer Sport Trac Sensor Assembly

Part Number: F85Z-9G444-BA$68.72 MSRP: $93.90You Save: $25.18 (27%)Ships in 1 Business DayFord Explorer Sport Trac Exhaust Gas Oxygen Sensor

Part Number: 4L3Z-9G444-AA$56.43 MSRP: $93.27You Save: $36.84 (40%)Ships in 1 Business DayFord Explorer Sport Trac Sensor - Hego

Part Number: XL3Z-9F472-BA$38.30 MSRP: $61.09You Save: $22.79 (38%)Ford Explorer Sport Trac Sensor - Hego

Part Number: F85Z-9G444-AB$55.77 MSRP: $92.18You Save: $36.41 (40%)Ships in 1 Business Day

Ford Explorer Sport Trac Oxygen Sensors

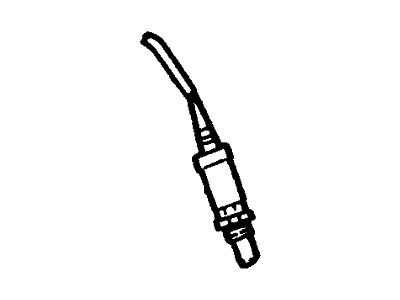

The Oxygen Sensors in Ford explorer sport trac vehicles relate to the monitoring of the air /fuel mixture in the engine exhaust. It is able to measure the amount of unused oxygen and compare it to the surrounding oxygen concentration and then sends a voltage signal to the engine control computer regarding the richness or the leanness of the mixture. This feedback lets the computer control the fuel injector pulse width and keep the catalytic converter working properly while minimizing emission. Ford Explorer Sport Trac automobiles normally have not less than 2 oxygen sensors, a upstream and a downstream of the catalytic converter, with the upstream oxygen sensor normally being the one that feeds again information. These sensors work at high temperatures; they can degrade or be contaminated and hence lead to the production of high emissions and low fuel economy. There are new car models that come with air/fuel ration sensors other than the oxygen sensors with broader air/fuel mixture gauging capacity.

We provide a wide range of Ford Explorer Sport Trac Oxygen Sensors at the best prices possible. If you need Ford Explorer Sport Trac Oxygen Sensors, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Sport Trac Oxygen Sensors Parts Questions & Experts Answers

- Q: What are the guidelines for troubleshooting Oxygen Sensors (O2S) on Ford Explorer Sport Trac?A:Before attributing the oxygen sensor to driveability problems, thorough tests should be carried out. The PCM controls the engine air/fuel ratio through the upstream O2S. The downstream O2S is used in the catalyst monitor system. A working O2S needs good connections, air supply, temperature, and unleaded fuel. HO2S faults are detected by the EEC system through trouble codes. This is done by checking O2S signal voltage with a voltmeter which should range from 100 to 900 millivolts for both sensors. Be careful during sensor removal so as not to damage it, get it dirty, or use cleaning solvents. Install an anti-seize compound on the threads before screwing in the sensor. Lifting the vehicle up is part of the removal process, then comes detaching the electrical connector, unscrewing the old sensor using a specialized socket, applying anti-seize compound, tightening a new sensor safely and finally connecting the electrical connector.