My Garage

My Account

Cart

Genuine Ford Explorer Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

39 Drive Belts found

Ford Explorer V-Belt

Part Number: BB5Z-8620-A$54.86 MSRP: $92.36You Save: $37.50 (41%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: GB5Z-8620-A$27.84 MSRP: $45.09You Save: $17.25 (39%)Ships in 1-2 Business DaysFord Explorer Belt

Part Number: DA8Z-8620-A$23.35 MSRP: $37.82You Save: $14.47 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: GB5Z-8620-B$24.91 MSRP: $40.36You Save: $15.45 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: 9L2Z-8620-A$29.07 MSRP: $47.09You Save: $18.02 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: 4L2Z-8620-EA$46.14 MSRP: $74.75You Save: $28.61 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: 4L2Z-8620-FA$46.80 MSRP: $75.82You Save: $29.02 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: 6L2Z-8620-CA$45.24 MSRP: $73.27You Save: $28.03 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: 1L2Z-8620-AB$46.14 MSRP: $74.75You Save: $28.61 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: FB5Z-8620-A$24.91 MSRP: $40.36You Save: $15.45 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: 1L2Z-8620-DA$46.80 MSRP: $75.82You Save: $29.02 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: F5TZ-8620-D$42.76 MSRP: $69.27You Save: $26.51 (39%)Ships in 1-2 Business Days

Ford Explorer V-Belt

Part Number: L1MZ-8620-B$27.05 MSRP: $43.82You Save: $16.77 (39%)Ships in 1-3 Business DaysFord Explorer V-Belt

Part Number: L1MZ-8620-F$37.10 MSRP: $51.64You Save: $14.54 (29%)Ships in 1-3 Business DaysFord Explorer V-Belt

Part Number: BL3Z-8620-H$38.16 MSRP: $61.82You Save: $23.66 (39%)Ships in 1-2 Business DaysFord Explorer V-Belt

Part Number: L1MZ-8620-H$35.36 MSRP: $57.27You Save: $21.91 (39%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 39 Results

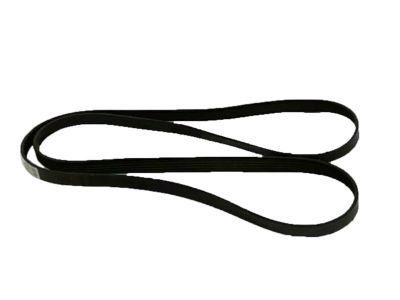

Ford Explorer Drive Belt

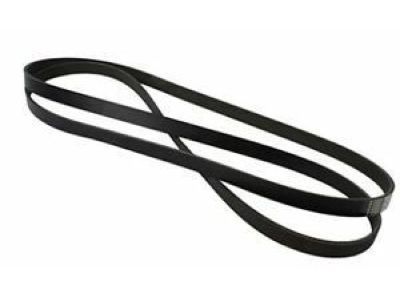

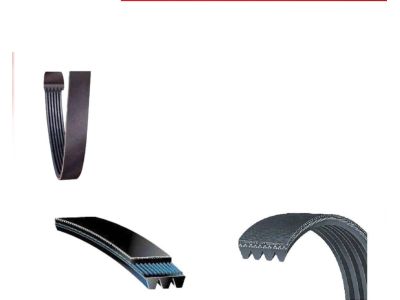

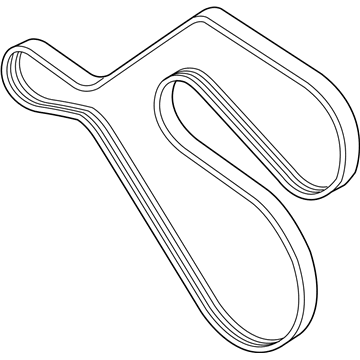

The drive belt in Ford Explorer is very important because it helps connect the engine to other driven parts including the alternator among others. Generally, a serpentine belt is used, which goes round these parts and connects them with the crankshaft pulley. Such a design provides for the power delivery to the parts where the engine can simultaneously power several parts. The Ford Explorer models over the years have incorporated various types of Drive Belts, the V-belts and the multi-groove belts. Compared to conventional belts, standard V-belts have very good grip and rating for strength while multi V-belts can be more flexible and efficient to cater for intricate transfer routes. Maintenance is required frequently, as Drive Belts typically need to be replaced after 100,000 miles but if they get rusty or have some frays or cracks, they have to be replaced sooner. A bad Drive Belt may result in a myriad of complications concerning the parts as well as the engine in Ford Explorer automobiles, so it is advisable to change it when it is worn out.

We provide a wide range of Ford Explorer Drive Belt at the best prices possible. If you need Ford Explorer Drive Belt, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Drive Belt Parts Questions & Experts Answers

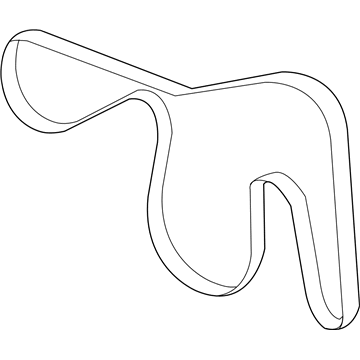

- Q: What is the importance of the accessory drive belt in engine operation on Ford Explorer?A:The front belt is one accessory belt responsible for turning the water pump, the alternator, the power steering pump and the air conditioning compressor. For the proper engine operation, its condition and tension are crucial; high tension results in bearing abrasion, low tension in slippage and belt noise vibration, and possible failure. Drive belts are made up of multiple layers of material woven together and therefore always under high tension but this tension as well as the heat takes its toll on the belts and they have to be regularly inspect. Belt also incorporates a serpentine tensioner that does not need being adjusting throughout the use of the belt. These vehicles employ a single v-ribbed serpentine belt and this belt goes round in a complicated way round different pulleys. To examine the belt, switch off the engine and take off the hood: flash light should be used in this case to look for signs of possible rubber plies separation, severed cores, rib separation, fraying and glazing of the belt. Admissible imperfections are slight diagonal crack runs and small portions missing from the ribs and, if more than ½ inch chunks are missing from two neighboring ribs, or if noise is produced, substitution is required. Though quite simple in design, the belt sides must be checked, and in order to inspect the bottom side of it, one will have to twist it. To remove the serpentine belt, turn the tensioner anti-clockwise in order to loosen the tension so as to remove the belt from the pulleys. To replace a belt, more often than not, the tensioner has to be in the released position; further, a new belt should be correctly placed and ensure that the ribs hook on the pulley ribs before releasing the tensioner.

Related Ford Explorer Parts

Browse by Year

2025 Drive Belt 2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1992 Drive Belt 1991 Drive Belt