My Garage

My Account

Cart

Genuine Mercury Mariner EGR Valve

Emissions EGR Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 EGR Valves found

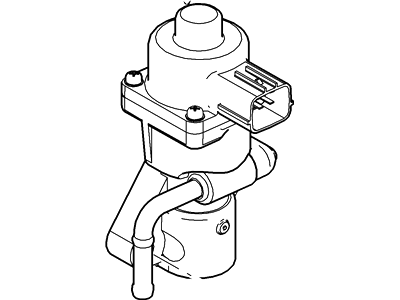

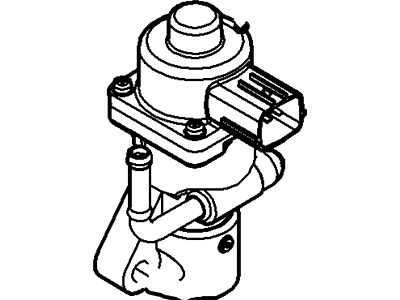

Mercury Mariner Exhaust Gas Recirculation Valve

Part Number: 7L8Z-9D475-AA$195.96 MSRP: $334.55You Save: $138.59 (42%)Ships in 1-2 Business DaysMercury Mariner Valve Assembly

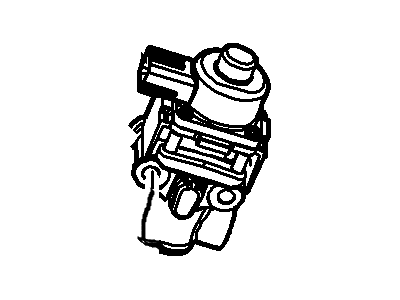

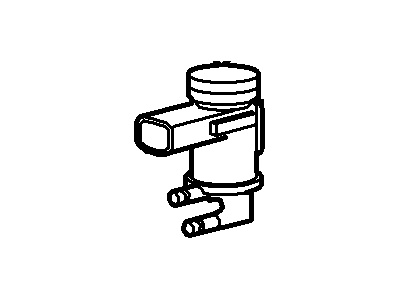

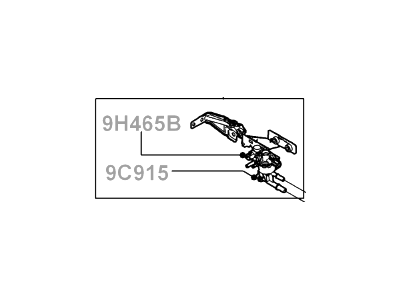

Part Number: E8AZ-9H465-A$26.51 MSRP: $37.77You Save: $11.26 (30%)Ships in 1-3 Business DaysMercury Mariner Exhaust Gas Valve

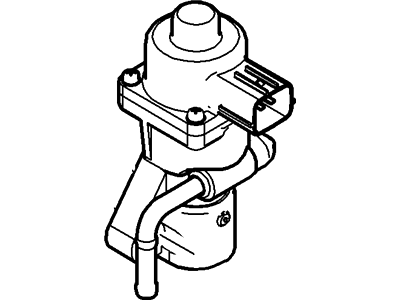

Part Number: 9L8Z-9D475-A$93.83 MSRP: $155.09You Save: $61.26 (40%)Ships in 1-2 Business DaysMercury Mariner Exhaust Gas Valve

Part Number: 1S7Z-9D475-AA$75.13 MSRP: $124.18You Save: $49.05 (40%)Ships in 1-2 Business DaysMercury Mariner Valve Assembly

Part Number: E8AZ-9H465-B$29.00 MSRP: $41.32You Save: $12.32 (30%)Ships in 1-2 Business DaysMercury Mariner Exhaust Gas Recirculation Valve

Part Number: 9E5Z-9D475-A$187.44 MSRP: $320.00You Save: $132.56 (42%)Ships in 1-3 Business DaysMercury Mariner Exhaust Gas Recirculation Valve

Part Number: XR1Z-9D475-AB$79.69 MSRP: $127.09You Save: $47.40 (38%)

Mercury Mariner EGR Valve

We provide a wide range of Mercury Mariner EGR Valve at the best prices possible. If you need Mercury Mariner EGR Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Mariner EGR Valve Parts Questions & Experts Answers

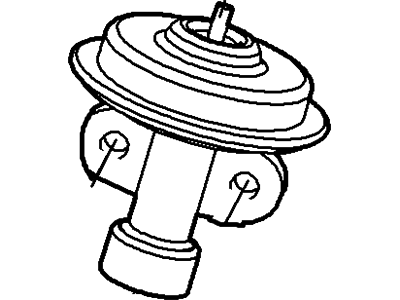

- Q: What is the general description and component replacement process for Exhaust Gas Recirculation systems and EGR Valve on Mercury Mariner?A:Exhaust gas recirculation (EGR) systems in late-model vehicles serve two key purposes, lowering oxides of nitrogen (NOx) emissions and preventing significant engine knock or detonation. Again, by injecting into the intake manifold a low proportion of the exhaust, combustion temperatures are reduced since exhaust contains gases which do not burn. These combustion temperatures are higher than 2500 F and result in high NOx formation; they, in conjunction with HC and sunlight, cause photochemical smog. EGR systems are generally claimed to run with minimal problems and the failures are reported to occur when the EGR valve is closed or fully open. There may not be visible sign of a closed valve but it may cause engine detonation or overheating whenever it is under load and on the other hand, an open valve may cause rough engine operation and stalling. In component replacement, the procedure include lifting of the vehicle and removing of some connecting part such as EGR pipe and the valve in addition, the identities of all old gasket and deposits before fitting. One has to be extremely careful whenever the EGR pipe is removed from the valve, and always ensure that the pipe is changed together with the threads with any sign of deterioration. After reassembly there is need to make sure that the PCM relearns for its idle as well as for the fuel trim strategy.