My Garage

My Account

Cart

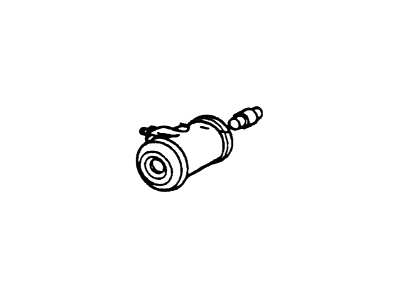

Genuine Mercury Capri Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Wheel Cylinder found

Mercury Capri Wheel Cylinder

Mercury Capri vehicles use the Wheel Cylinder as part of their hydraulic drum brake system to ensure effective stopping by pushing brake shoes against the brake drum. Each brake cylinder expands multiple pistons under hydraulic pressure to send the brake shoes against the brake drum surface. The components of this construction include a cast iron or aluminum body and rubber-sealed pistons together with an expander spring for maintaining seal pressure. Multiple Wheel Cylinder design variations have been introduced throughout history with dual single-piston units forming one of these designs. The current manufacturing of Mercury Wheel Cylinders consists mainly of aluminum materials since cast iron versions have been replaced by rust-resistant components. A Capri Wheel Cylinder's durability does not eliminate its susceptibility to brake fluid moisture corrosion which shows as leaks thus drivers must inspect Mercury Capri Wheel Cylinders and might need either replacement or rebuilding to maintain peak braking functionality.

We provide a wide range of Mercury Capri Wheel Cylinder at the best prices possible. If you need Mercury Capri Wheel Cylinder, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Capri Wheel Cylinder Parts Questions & Experts Answers

- Q: How to overhaul and install a wheel cylinder on Mercury Capri?A:When overhaul may be required, often because of fluid leakage or a sticky lifter, consider all possibilities before starting the work. New wheel cylinders are currently in stock, and as such, this is quite an easy task. If the decision is made to rebuild the wheel cylinder, make certain that there is a rebuild kit prior to starting. The practice is always to replace both wheel cylinders at the same time. First, use the car jack to lift the rear of the vehicle and then use the jackstands to support the car and also lock the front wheels to not move. Loosen the brake shoe assembly and cleaning all round the wheel cylinder to eliminate any dirt or any foreign material. Unfit the Brake Line and free the line by unscrewing the two bolts in the wheel cylinder and by taking out the fitting but you don't have to pull the line up from the cylinder. Third, the wheel cylinder mounting bolts are then withdrawn, the cylinder unmelded from the brake backing plate and set on the bare workbench, then the brake line has to be plugged avertfully to reduce loss and contamination of the fluid. In the overhaul, take out the bleeder screw, cups, pistons, boots as well as the spring assembly from the wheel cylinder body. Soak the cylinder with brake fluid and scrub it with denatured alcohol or brake system cleaner then blow the fluid and the passages with compressed air. Examine the cylinder bore for rust and score marks; mild rust can be rubbed off with crocus paper, if the defects cannot be rubbed off or if the bore is scored, the cylinder has to be replaced. Coat brand new cups in brake fluid and fit the other components of the brake cylinder with the cup lips pointed internally. The procedure for installation includes; firstly, positioning the wheel cylinder and then installing the bolts while the brake line is connected and before re installation of the brake shoe assembly the brake line must be bled.