My Garage

My Account

Cart

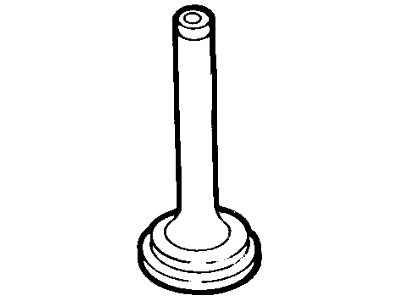

Genuine Mercury Capri Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Exhaust Valves found

Mercury Capri Valve Exhaust

Part Number: E9SZ6505A$18.13 MSRP: $24.77You Save: $6.64 (27%)Ships in 1-2 Business Days

Mercury Capri Exhaust Valve

We provide a wide range of Mercury Capri Exhaust Valve at the best prices possible. If you need Mercury Capri Exhaust Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Capri Exhaust Valve Parts Questions & Experts Answers

- Q: Should servicing of valves, valve seats, and valve guides be done by a professional on Mercury Capri?A:As seen, because of the nature of the job and the tools that needs to be used, the process of working on the valve, valve seats and the valve guides that is often referred to as valve job, should only be done by a professional. With the head removed and dismantled, a home mechanic is in a position to provide initial washing and inspection of the part before reassembling it for delivering to a dealer service department or an automotive machine shop for the actual work to be done on the head. Carrying out the inspection makes it possible to get an understanding of the state of head and valve train parts thus; knowing the work required and new parts when dealing with an automotive machine shops. For the specific services described below, responsibility will lie with the dealer service department or automotive machine shop: valve removal, valve or spring reconditioning or replacement, checking and replacing valve guides, valve spring, spring retainer, rotator or keepers as necessary, replacing valve seals, reassembling valves, and verifying the accuracy of the installed spring height, among others. Also, if the surface of the cylinder head gasket is uneven, this will also be machined. After the valve job is done the head will be smooth as new, after this another washing may be done to remove the remaining metal particles and abrasive grit that may be remaining following the head machining or the valve service. It is also blown through all oil holes and passages using compressed air.