My Garage

My Account

Cart

Genuine Mercury Capri Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Clutch Discs found

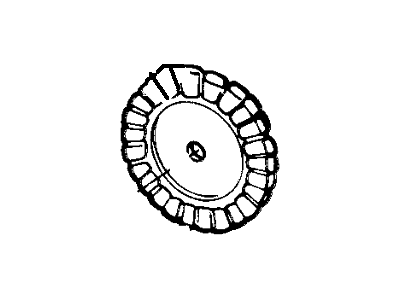

Mercury Capri Clutch Disc Assembly

Part Number: FOZZ-7550-A$177.38 MSRP: $253.85You Save: $76.47 (31%)Ships in 1-3 Business Days

Mercury Capri Clutch Disc

The Clutch Disc in Mercury Capri vehicles bridges the engine with the transmission's input shaft to provide smooth gear transmission. The two sides of this component contain friction material that interacts with the flywheel and pressure plate for engine power transmission. Gear changes become possible for the vehicle when drivers press the clutch pedal because the pressure plate disengages from the Mercury Clutch Disc. Several forms of Mercury Capri Clutch Disc exist in the market which include organic material while ceramic material and advanced compounds such as kevlar and sintered iron make up the high-performance section. The primary use of organic Capri Clutch Disc is standard driving but ceramic and kevlar materials provide specialized performance enhancement through durable mechanisms that resist high temperatures. The system features either sprung or rigid hubs among its design elements where sprung hubs work to minimize operational shocks. The system requires proper maintenance because excessive wear causes the clutch to malfunction through slippage problems.

We provide a wide range of Mercury Capri Clutch Disc at the best prices possible. If you need Mercury Capri Clutch Disc, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Capri Clutch Disc Parts Questions & Experts Answers

- Q: How to inspect and replace Clutch Disc and Pressure Plate on Mercury Capri?A:The real estates of the clutch components are gotten via the stripping off of the transmission while the engine remains in the automobile. In cases where the engine has to be pulled as has been discussed in the process of a major overhaul, it is prudent to inspect the clutch for possible wear and carry out a replacement of all worn out parts. First, lay the transmission on a transmission jack or other lifting device and support the engine by having the engine hoisted from above or you can just use a jack with a piece of wood between the jack, and oil pan. In models containing a mechanical release system, void the clutch release cable while in the models containing hydraulic release system, eliminate the slave cylinder but do not disconnect the hydraulic line. Then, it is necessary to uninstall the bellhousing-to-engine bolts and take the housing off, which can be done by applying some twisting forces, lightly. It is possible to leave the clutch fork and Release Bearing joined for the time being. During the clutch disc withdrawal process, there is a need to support the clutch disc and one of the ways of doing this is by introducing clutch alignment tool through the clutch disc hub. Look for indexing marks on the flywheel and pressure plate and if there are none then draw your own, so as to align every time you want to reinstall. Remove the pressure plate-to-flywheel bolts rather loosely in a diagonal sequence to ease pressure in the spring then remove the pressure plate and the clutch disc. Make the following checks on the flywheel and clutch: for cracks, and other defects: the clutch disc lining should be at least 1/16-inch above the rivet heads, if not replace the clutch. The release bearing is usually changed simultaneously with the clutch disc and the pressure plate must be inspected for signs of wear and damage and refinished or replaced if possible. In general, before the installation, the two similar surfaces, namely the flywheel surface and pressure plate surface, must be made clean to eliminate contaminants interferements. Align the clutch disc and pressure plate by inserting the alignment tool in the pressure plate indicating the correct orientation and tighten the pressure plate to flywheel bolts to the extent that it could be done only by the fingers. Align the clutch disc using the alignment tool and fasten all the bolts in a crosswise fashion and then finally tighten to the recommended torque and then remove the alignment tool. Grease high temperature the release bearing and the contact surfaces of the release lever and then fit the release bearing loosely and then fit the bell housing which should be tightened to a standard torque setting. Last but not the least, replace the transmission, slave cylinder or release cable, during reinstalling make sure all fasteners have been tightened appropriately and to the factory torque setting if required.