My Garage

My Account

Cart

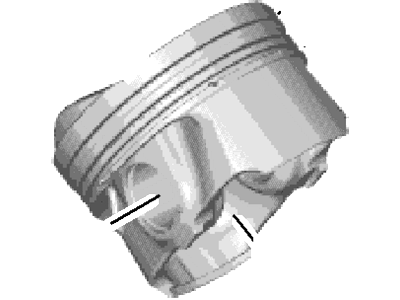

Genuine Lincoln Navigator Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Pistons found

Lincoln Navigator Piston

Part Number: HL7Z-6108-F$193.12 MSRP: $282.33You Save: $89.21 (32%)Ships in 1-2 Business DaysLincoln Navigator Piston

Part Number: 3L3Z-6108-CC$54.49 MSRP: $78.28You Save: $23.79 (31%)Ships in 1-3 Business DaysLincoln Navigator Piston And Pin Assembly

Part Number: 2L3Z-6108-AA$112.36 MSRP: $164.27You Save: $51.91 (32%)Lincoln Navigator Piston And Pin Assembly

Part Number: XL3Z-6108-EA$169.29 MSRP: $247.50You Save: $78.21 (32%)Lincoln Navigator Piston

Part Number: HL7Z-6108-J$152.99 MSRP: $223.67You Save: $70.68 (32%)Ships in 1-3 Business DaysLincoln Navigator Piston And Pin Assembly

Part Number: XL3Z-6108-KA$112.18 MSRP: $173.43You Save: $61.25 (36%)Lincoln Navigator PISTON AND PIN ASY

Part Number: HL7Z-6108-K$193.12 MSRP: $282.33You Save: $89.21 (32%)Lincoln Navigator Piston And Pin Assembly

Part Number: HL7Z-6108-H$133.62 MSRP: $207.17You Save: $73.55 (36%)Ships in 1-3 Business DaysLincoln Navigator Piston And Pin Assembly

Part Number: XL3Z-6108-DA$169.29 MSRP: $247.50You Save: $78.21 (32%)Lincoln Navigator Piston

Part Number: NL3Z-6108-A$173.05 MSRP: $253.00You Save: $79.95 (32%)Ships in 1-2 Business DaysLincoln Navigator Piston

Part Number: 3L3Z-6108-DB$120.64 MSRP: $182.78You Save: $62.14 (34%)Ships in 1-2 Business DaysLincoln Navigator PISTON AND PIN ASY

Part Number: NL3Z-6108-C$173.05 MSRP: $253.00You Save: $79.95 (32%)Ships in 1-2 Business DaysLincoln Navigator Piston

Part Number: HL7Z-6108-G$141.70 MSRP: $207.17You Save: $65.47 (32%)Ships in 1-3 Business DaysLincoln Navigator Piston And Pin Assembly

Part Number: XL7Z-6108-CA$22.10 MSRP: $30.71You Save: $8.61 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 31 Results

Lincoln Navigator Piston

The Piston in Lincoln Navigator automobiles are part and parcel of internal combustion engines since they offer the leverage upon which combustion energy is harnessed to provide energy for the automobiles' movement. Transforming force exerted by expanding gaseous pressures into the direction of crankshaft, the Lincoln Navigator's Piston also holds the primary responsibility of enhancing the engine performance under higher pressures and temperature conditions. In the course of its production various types of Pistons have been used in Lincoln Navigator for instance trunk pistons which provide side forces and have the functionality of oil rings which act as lubricants. Furthermore, special racing pistons may also be used for performance improvements, which gravitates to light weight while at the same time being strong enough to support high RPM's. The kind of Piston that is used has a close relationship with the efficiency and durability of the Lincoln Navigator which is why careful engineering in its creation cannot be overemphasized.

We provide a wide range of Lincoln Navigator Piston at the best prices possible. If you need Lincoln Navigator Piston, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln Navigator Piston Parts Questions & Experts Answers

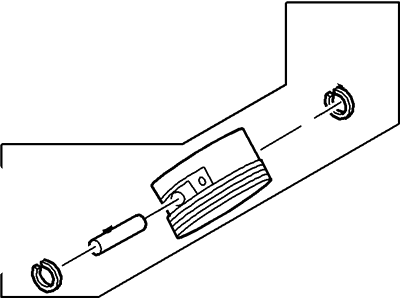

- Q: How to remove the piston and connecting rod assemblies on Lincoln Navigator?A:Before, the piston and connecting rod assemblies can be removed, the cylinder head(s), oil pan and oil pump on 5.4L engines have to be taken off depending on the type of engines being overhauled. A few of those models may include a sheet metal oil baffle plate secured with nuts to the main cap studs that must be removed. Push with the edge of a fingernail along a line 1 / 4 inch below the top of each cylinder where there should be a ring ridge; if the latter is worn or clogged with carbon, it must be machined out with a reamer before trying to extract the piston and its associated connecting rod as the former may break. After that, after the removal of the ridges, flip the engine over with the Crankshaft horizontal. When the connecting rods are ready to be removed, check the end play with dial indicator or feeler gauges; the end play should not be over the service limit; if it is so, it means that a new set of connecting rods may be required. Tag the connecting rods and caps, turn the cap bolts with progressively lesser strength until they can be hand-turned. Both the connecting rod cap and the bearing insert must be taken off, but the latter part should be done carefully, as it is easy to lose it. The V6 and VS engines incorporate a fractured cap process in that the rod cap is matched to the connecting rod so that one cap will not fit another. As it is difficult to avoid scratches on the rod journals when disassembling or assembling, two of the rod cap bolts are to be machined to act as sleeves for the journals to reduce chances of scratching. New torque to yield design bolts will be used during the assembly request while the old ones should be disposed. Force the connecting rod/piston assembly through the top of the engine with a wooden or plastic hammer handle, if there is still some resistance, be sure to knock off all the ridges. Perform the same for the other cylinders as well Continue on this process until all the cylinders have been tested. After removal, reinsert the connecting rod caps and bearing inserts into its corresponding connecting rods ensuring that the cap nuts are only tightened by hand in order not to mar the bearing interfaces. It is for this reason that one has not to disconnect the pistons from the connecting rods.