My Garage

My Account

Cart

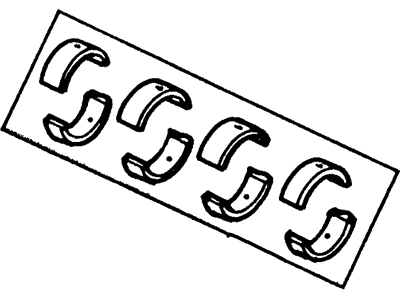

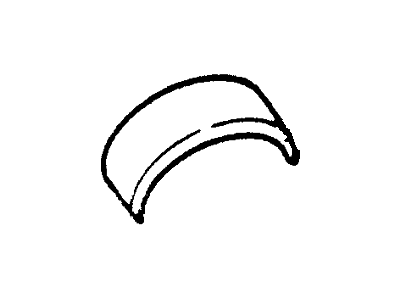

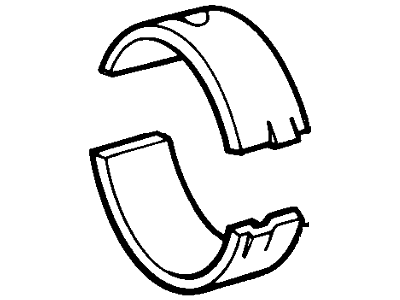

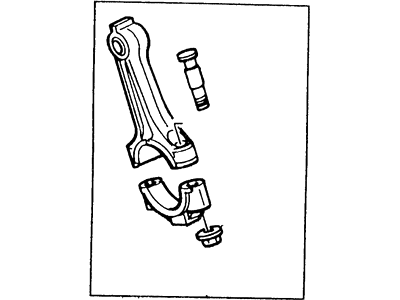

Genuine Ford Thunderbird Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Rod Bearings found

Ford Thunderbird Connecting Rod Bearing

Part Number: D2RY-6211-C$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business DayFord Thunderbird Connecting Rod Bearing

Part Number: XL2Z-6211-FA$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business DayFord Thunderbird Connecting Rod Bearing

Part Number: F4SZ-6211-A$13.73 MSRP: $18.75You Save: $5.02 (27%)

Ford Thunderbird Rod Bearing

In Ford Thunderbird cars the Rod Bearing plays an important function as it provides support to crankshaft and connecting rods to rotate freely with less friction. Such bearings are normally plain bearings and they may be bi-metal, tri-metal or bi-emerald in design. Bi-metal Rod Bearings come with an aluminum alloy lining usually backed by silicone for the purpose of increasing its hardness while the tri-metal Rod Bearings have copper alloy layer along with lead-tin-copper overlay to bring high strength and fatigue characteristics to this bearing. Through the years, Ford Thunderbird Rod Bearings have been upgraded, while performance models on road cars typically feature bearings with three metals, with a high technology metal plus coating to minimize stick-slip and to boost service life. These performance Rod Bearings are designed for high revving engines, and has certain changes like oil-journal clearance and lubrication channels. get the optimal Ford Thunderbird Rod Bearings especially its installation and maintenance for better performance and durability of the engine.

We provide a wide range of Ford Thunderbird Rod Bearing at the best prices possible. If you need Ford Thunderbird Rod Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Thunderbird Rod Bearing Parts Questions & Experts Answers

- Q: What are the key factors contributing to bearing failure on Ford Thunderbird?A:To say the least, when reconditioning an engine, it is required to use new main and connecting rod bearings although the old ones should be retained for serious examination as these will give a clue on the engine. Causes of bearing failure include lack of lubrication, contaminants such as dirt or particles, overworking the engine, and corrosion and such problems must not be overlooked while disassembling but fixed to avoid being repeated. When inspecting the bearings, they should be pulled out of the engine block and spread on a flat surface in their original position in order that problems be matched with the crankshaft journal. Foreign particles can be got into the engine during assembly, in passing through the filter or through the PCV system or from tramp metals and abrasive from the machining or after reconditioning. Contaminants can be incorporated into the bearing metal matrix, while undergone material resulting in scoring or gouging can result from the large size particles. Thus, to avoid such failures, cleaning of all parts and routine engine oil and filter should be done. Failure of greasing can be consequent of high temperatures, overloading, leaking or choked oil channels which may cause serious damage such as extrusion of bearing surface material right from its metal jacket. Other dynamic considerations also greatly influence bearing life; when a vehicle is raced at low speeds, high loads are obtainable that can push out the oil film whereas short distance travel can cause corrosion because of inadequate heat build up. Also, wrong orientation of bearings can lead to oil starvation because they may be pressed in tightly or because of dirt, debris and gunk trapped behind inserts leading to high spot fatigue failure.

Related Ford Thunderbird Parts

Browse by Year

1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing 1986 Rod Bearing 1985 Rod Bearing 1984 Rod Bearing 1983 Rod Bearing 1982 Rod Bearing 1981 Rod Bearing 1980 Rod Bearing