My Garage

My Account

Cart

Genuine Ford Taurus Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Turbochargers found

Ford Taurus Turbocharger Assembly

Part Number: AA5Z-6K682-D$791.14 MSRP: $1310.91You Save: $519.77 (40%)Ships in 1-3 Business DaysFord Taurus Turbocharger Assembly

Part Number: AA5Z-6K682-CA$761.27 MSRP: $1261.09You Save: $499.82 (40%)Ships in 1-3 Business DaysFord Taurus Turbocharger Assembly

Part Number: CJ5Z-6K682-E$753.47 MSRP: $1301.82You Save: $548.35 (43%)Ships in 1-2 Business DaysFord Taurus Turbocharger Assembly

Part Number: AA5Z-6K682-B$791.14 MSRP: $1310.91You Save: $519.77 (40%)Ships in 1-3 Business DaysFord Taurus Turbocharger Assembly

Part Number: AA5Z-6K682-A$761.27 MSRP: $1261.09You Save: $499.82 (40%)Ships in 1-3 Business DaysFord Taurus Turbocharger Assembly

Part Number: AA5Z-6K682-C$761.27 MSRP: $1261.09You Save: $499.82 (40%)Ships in 1-3 Business Days

Ford Taurus Turbocharger

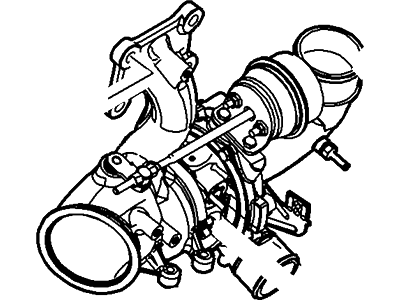

Turbocharger in Ford Taurus Automobile is aimed to boost the performance of its engine by utilizing the power of exhaust gases that turns a turbine to compress air and supply it to engine. This procedure is popularly referred to as boosting which enhances on the powers of Ford Taurus on fuel efficiency than the normal air intake methods. For the Ford Taurus, there has been an active use of Turbochargers over the years and the latest technologies, which include twin-scroll as well as variable-geometry turbos. These new techniques are aimed at minimising the lag problem and improve the throttle response, some of the historic drawbacks of turbocharging. Thus, the application of turbochargers enhances the performance of the Ford Taurus but ahs limitations, which include higher exhaust temperatures and failures.

We provide a wide range of Ford Taurus Turbocharger at the best prices possible. If you need Ford Taurus Turbocharger, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Taurus Turbocharger Parts Questions & Experts Answers

- Q: What precautions should be taken when handling the turbocharger and How to its remove and install on Ford Taurus?A:The wastegate actuator should not be adjusted and the turbocharger should not be taken apart, because this can cause damage to either the turbocharger or the engine. When removing the turbocharger, charge air cooler or cooler tubes always ensure that all openings are masked off to minimise the entry of dirt and have all openings cleaned thoroughly while re-assembly. If you want to remove the turbocharger then lift the automobile and then support it using jack stands safely. Third, eliminate the 'cattie', next is the charge air cooler inlet tube and then the turbocharger inlet pipe. Withdraw the nuts and bolts holding the cold air duct and remove the turbocharger heat shield then dump all the water in the coolant system. Moving upwards, retract the hose clamps on the coolant line and, from below, undo the coolant outlet line banjo bolt and disconnect the line from both the turbocharger and engine block, don't forget to change the linked sealing washers. Loosen the oil supply line banjo bolts and extract the sealing washers and then the in line oil supply filter which should be replaced. Remove the electrical connectors from the turbocharger, undo the vacuum lines and the coolant lines coming from the right part of the turbocharger, also unscrew the mounting bolts of the oil drain tube and the tube itself, again there should be a gasket, it should be discarded. The oil drain tube has to be replaced if it has been removed in any case. Take off and dispense with the turbocharger mounting nuts; subsequently, the turbocharger ought to be gently drawn out of the said vehicle. Remove the studded by using the stud removal tool; discharging the turbocharger studs with the cylinder head. For installation; four new studs must be installed in the cylinder head after which the turbocharger must be installed and the nuts tightened to the recommended torque. New oil drain tube and gasket to be fitted and while tightening bolts to the torque of 25 ft-lbs., the new sealing washers for the oil feed line as well as the coolant lines to be fitted by tightening the banjo bolts to the torque of 17 ft-lbs. All the rest of the installation is done inversely to its removal. And, last, add more fluids to the cooling system and replace the engine oil with a fresh one and the filter too.