My Garage

My Account

Cart

Genuine Ford Fusion PCV Hose

PCV Valve Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 PCV Hoses found

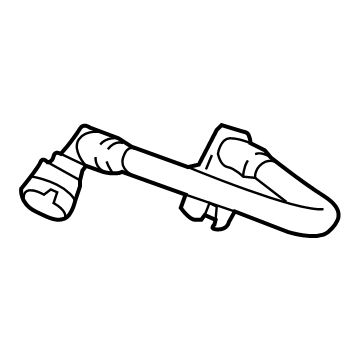

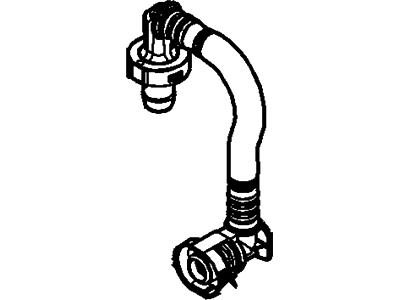

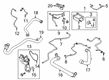

Ford Fusion Vent Hose

Part Number: BM5Z-6A664-H$55.78 MSRP: $82.83You Save: $27.05 (33%)Ships in 1-2 Business DaysFord Fusion Evaporative Emissions System Lines

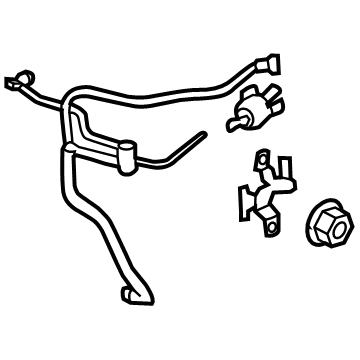

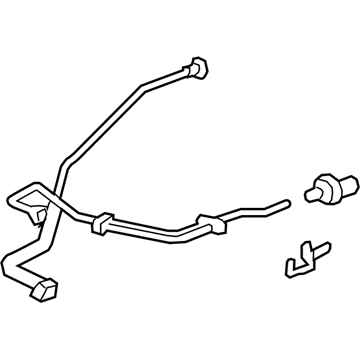

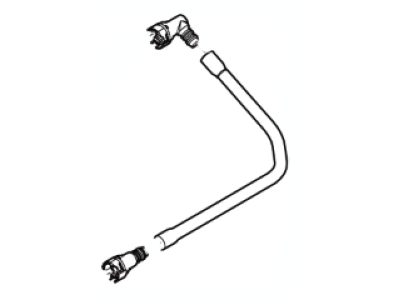

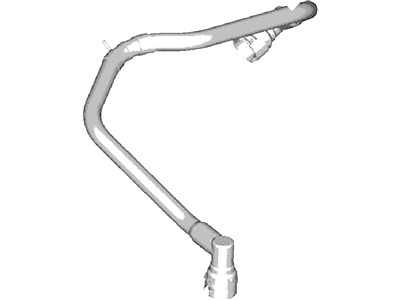

Part Number: EJ7Z-6758-D$85.65 MSRP: $125.22You Save: $39.57 (32%)Ford Fusion Tube Assembly

Part Number: EJ7Z-6758-A$85.65 MSRP: $125.22You Save: $39.57 (32%)Ships in 1-3 Business Days

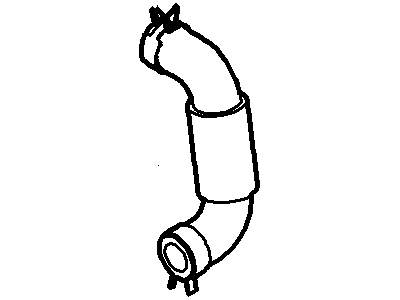

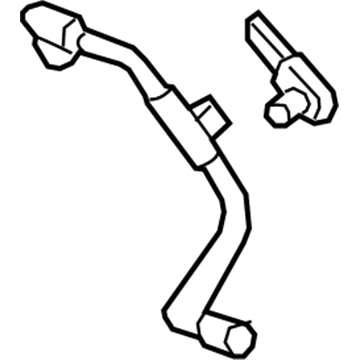

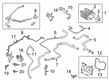

Ford Fusion Breather Tube

Part Number: HS7Z-6A664-C$139.75 MSRP: $216.67You Save: $76.92 (36%)Ships in 1-2 Business DaysFord Fusion Vent Hose

Part Number: BM5Z-6A664-B$54.67 MSRP: $82.83You Save: $28.16 (34%)Ships in 1-2 Business Days

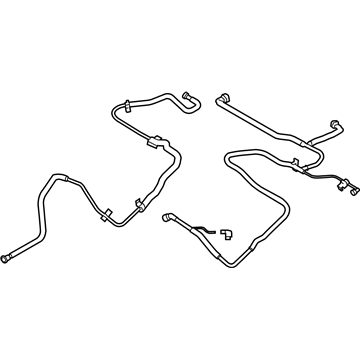

Ford Fusion Tube Assembly Fuel Vapour Separat

Part Number: HG9Z-9D289-F$168.72 MSRP: $246.67You Save: $77.95 (32%)Ships in 1-2 Business Days

Ford Fusion Fuel Vapour Separator Tube Assembly

Part Number: HG9Z-9D289-E$226.23 MSRP: $333.67You Save: $107.44 (33%)Ford Fusion Tube Assembly

Part Number: 3S4Z-6758-AA$31.86 MSRP: $45.38You Save: $13.52 (30%)Ships in 1-3 Business Days

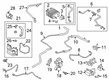

Ford Fusion Connector

Part Number: 8S4Z-6C324-E$52.32 MSRP: $75.17You Save: $22.85 (31%)Ships in 1-3 Business DaysFord Fusion Connector

Part Number: 8S4Z-6C324-C$51.87 MSRP: $75.17You Save: $23.30 (31%)Ships in 1-3 Business DaysFord Fusion Tube Assembly

Part Number: F2GZ-6758-A$67.84 MSRP: $99.18You Save: $31.34 (32%)Ships in 1-3 Business DaysFord Fusion Vent Hose

Part Number: 6E5Z-6A664-AA$16.93 MSRP: $24.75You Save: $7.82 (32%)Ships in 1-3 Business DaysFord Fusion Breather Tube

Part Number: HS7Z-6A664-A$139.75 MSRP: $216.67You Save: $76.92 (36%)Ships in 1-2 Business DaysFord Fusion Breather Tube

Part Number: DS7Z-6A664-BC$189.97 MSRP: $287.83You Save: $97.86 (34%)Ships in 1-3 Business DaysFord Fusion Tube

Part Number: HG9Z-9D661-H$288.96 MSRP: $482.00You Save: $193.04 (41%)Ships in 1-3 Business DaysFord Fusion Tube Assembly

Part Number: DS7Z-6758-J$30.50 MSRP: $43.45You Save: $12.95 (30%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 31 Results

Ford Fusion PCV Hose

We provide a wide range of Ford Fusion PCV Hose at the best prices possible. If you need Ford Fusion PCV Hose, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Fusion PCV Hose Parts Questions & Experts Answers

- Q: How to regularly inspect PCV hoses and other plastic, rubber, and metal pipes on Ford Fusion?A:Because the area beneath the hood of a vehicle overheats, leading to degradation of materials, rubber and plastic hoses must be regularly inspected in the engine, accessory, and emission systems. These hoses should be looked for cracks, loose clamps, hardening and leaks. Check if clamped hoses do not lose their tension that may lead to leakage. Make sure replacement hoses for vacuum are made of the same material. To fully assess hoses they might need to be removed from the vehicle; hence, mark hoses and fittings for proper reinstallation later. Pay attention to the t-fittings made of plastics that can crack easily and when they connect there is distortion on fitting and hose. Detecting vacuum leaks can be done by using a small piece of vacuum hose as stethoscope by feeling sounds produced by a hissing sound while probing with it around fittings and hoses. Be ready to catch spilled fuel while working with fuel hoses since they are usually pressurized. In particular check for deterioration, chafing and cracks especially at bends and near fittings.