My Garage

My Account

Cart

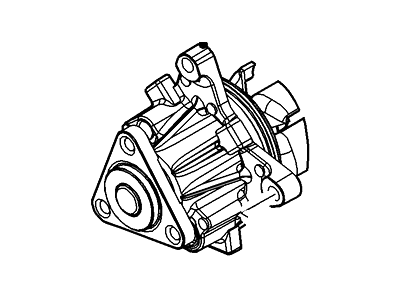

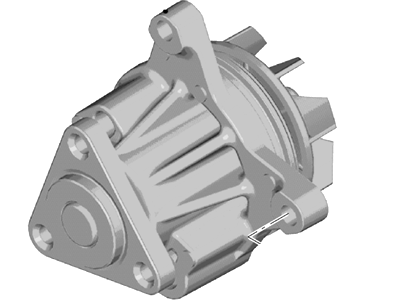

Genuine Ford Focus Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Water Pumps found

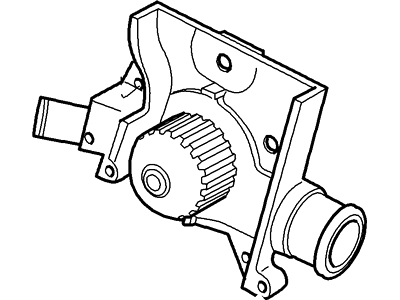

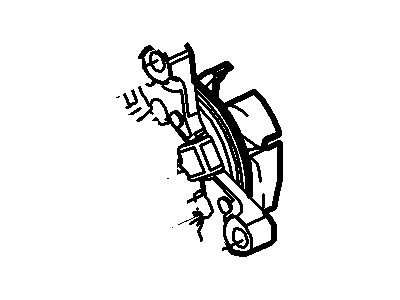

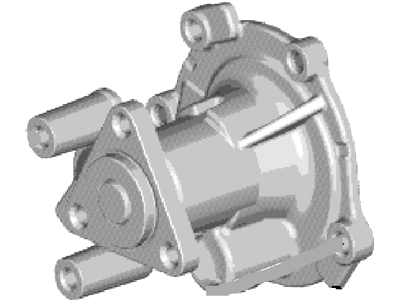

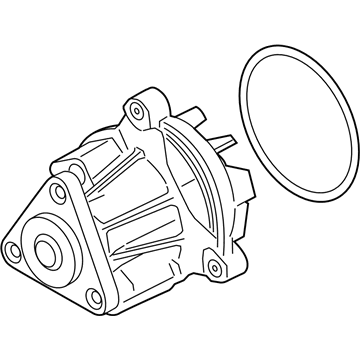

Ford Focus Water Pump Assembly

Part Number: YS4Z-8501-AA$34.57 MSRP: $47.24You Save: $12.67 (27%)Ships in 1-2 Business DaysFord Focus Water Pump Assembly

Part Number: 4S4Z-8501-AA$49.39 MSRP: $81.64You Save: $32.25 (40%)Ships in 1 Business DayFord Focus Water Pump Assembly

Part Number: CM5Z-8501-A$63.25 MSRP: $104.55You Save: $41.30 (40%)Ships in 1-2 Business DaysFord Focus Water Pump Assembly

Part Number: 4S4Z-8501-D$49.39 MSRP: $81.64You Save: $32.25 (40%)Ships in 1 Business DayFord Focus Water Pump Assembly

Part Number: 1S7Z-8501-AK$49.39 MSRP: $81.64You Save: $32.25 (40%)Ships in 1 Business DayFord Focus Water Pump Assembly

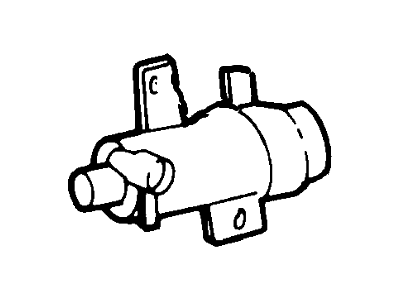

Part Number: EJ7Z-8501-F$47.99 MSRP: $76.55You Save: $28.56 (38%)Ships in 1-3 Business DaysFord Focus Pump Assembly

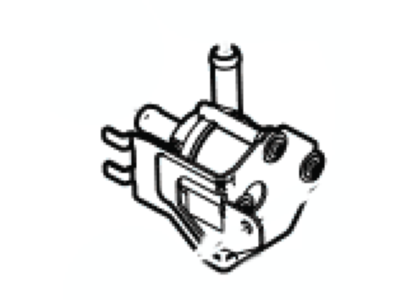

Part Number: CM5Z-8C419-A$60.26 MSRP: $101.64You Save: $41.38 (41%)Ships in 1-3 Business DaysFord Focus Pump Assembly

Part Number: EV6Z-8C419-A$241.98 MSRP: $403.64You Save: $161.66 (41%)Ships in 1-3 Business DaysFord Focus Pump Assembly

Part Number: CV6Z-8C419-A$381.50 MSRP: $636.36You Save: $254.86 (41%)Ships in 1-3 Business DaysFord Focus Water Pump Assembly

Part Number: EJ7Z-8501-C$47.99 MSRP: $76.55You Save: $28.56 (38%)Ships in 1-3 Business Days

Ford Focus Water Pump

The Water Pump in Ford Focus automobiles is a very significant part in making circulating the coolant from the radiator to the engine to allow for heat uptake from the combustion process. A majority of models include a belt-driven pump with an impeller and latter ones can include an electric water pump. These pumps are normally of aluminum with shaft provided with bearings so that coolant would not escape. There is an engine high-performance water pump that allows for enhanced coolant circulation and lesser power drawing from a conventional water pump. Furthermore, the use of electric water pumps has the following benefits like; the coolant circulation is dependant on the engine temperature and the pump runs after the engine has been turned off for cooling.

We provide a wide range of Ford Focus Water Pump at the best prices possible. If you need Ford Focus Water Pump, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Focus Water Pump Parts Questions & Experts Answers

- Q: How to check and replace a water pump on Ford Focus?A:Before starting the work, refer to the warnings given. To check the water pump's operation while it's installed on the engine, there are three methods: while the engine is running at normal operating temperature, squeezing the radiator top hose should result in a pressure surge when released if the water pump is working properly; check for coolant leaks from the weep or vent holes on the water pump, which indicate a failure in the pump seal; and listen for howling sounds at the drivebelt end of the engine while it's running, which could signal water pump shaft bearing failure, and verify shaft wear by rocking the water pump pulley up and down. If the water pump is defective, it should be replaced with a new or rebuilt unit. For removal, disconnect the negative battery cable, drain the cooling system, and loosen the water pump pulley bolts (a strap wrench may be needed to hold the pulley). Remove the auxiliary drivebelt and the water pump pulley, and on SPI engines, remove the timing belt, replacing it if necessary due to coolant contamination or approaching scheduled replacement. On non-SPI engines, the water pump can be removed without removing the timing belt, except for Zetec-E engines where the timing belt must be removed to access the water pump housing bolts if replacement is needed. Disconnect the coolant hose and unbolt the timing belt idler pulley before removing the water pump mounting bolts and, if necessary, the water pump housing. Clean the pump mating surfaces carefully, replace the gasket whenever disturbed, and ensure a new O-ring and clean coolant are used for water pumps with an O-ring seal. For installation, tighten all fittings to the specified torque settings, check the timing belt for contamination, and refill the cooling system upon completion.

Related Ford Focus Parts

Browse by Year

2018 Water Pump 2017 Water Pump 2016 Water Pump 2015 Water Pump 2014 Water Pump 2013 Water Pump 2012 Water Pump 2011 Water Pump 2010 Water Pump 2009 Water Pump 2008 Water Pump 2007 Water Pump 2006 Water Pump 2005 Water Pump 2004 Water Pump 2003 Water Pump 2002 Water Pump 2001 Water Pump 2000 Water Pump