My Garage

My Account

Cart

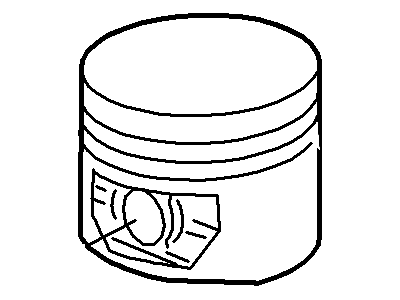

Genuine Ford Explorer Sport Trac Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Pistons found

Ford Explorer Sport Trac Piston And Pin Assembly

Part Number: 4L2Z-6108-A$88.98 MSRP: $123.61You Save: $34.63 (29%)Ships in 1-2 Business DaysFord Explorer Sport Trac Piston

Part Number: 4U7Z-6108-A$61.21 MSRP: $85.03You Save: $23.82 (29%)Ships in 1-2 Business Days

Ford Explorer Sport Trac Piston

The Piston in Ford Explorer Sport Trac vehicles is a very important component that helps in the transformation of combustion power into energy that is required to enable movement of the vehicle. This component is very useful in the internal combustion engine since it translates force exerted by the expanding gases into force on the crankshaft to enable the engine to function well. The Ford Explorer Sport Trac pistons are usually made from aluminum alloy with the aim of attaining a good combination of light weight and strength; high performance models may use forged or billet pistons. Through the years, there are various kinds of pistons used in the Ford Explorer Sport Trac, namely the trunk pistons that also take on side load and has oil ring for lubrication. Also, racing pistons are made with the intention of being light weight in order to increase performance during high RPMs. Through this, the design of these pistons is well designed to deliver the premier performance and durability thus playing a very important role in the Ford Explorer Sport Trac vehicles.

We provide a wide range of Ford Explorer Sport Trac Piston at the best prices possible. If you need Ford Explorer Sport Trac Piston, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Sport Trac Piston Parts Questions & Experts Answers

- Q: How to remove the piston and connecting rod assemblies on Ford Explorer Sport Trac?A:Prior to removing the piston and connecting rod assemblies, the cylinder head(s), oil pan, and oil pump must be taken off. Use your fingernail to check for any ridge at the upper limit of ring travel, approximately 1/4-inch down from the top of each cylinder. If ridges are present due to carbon deposits or cylinder wear, they must be completely removed with a ridge reamer before the pistons are taken out to avoid breakage. Ensure the tool does not cut into the ring travel area more than 1/32-inch. Once the ridges are removed, turn the engine upside-down with the Crankshaft facing up. Before removing the connecting rods, check the end play using a dial indicator or feeler gauges, sliding them between the first connecting rod and the crankshaft throw until the play is eliminated. If the end play exceeds the service limit, new connecting rods may be necessary. If new rods or a new crankshaft are installed, the end play might fall below the specified minimum, requiring machining of the rods. Check the connecting rods and caps for identification marks; if not marked, use a center-punch or scribe to create indentations on each rod and cap. Loosen the connecting rod cap nuts half a turn at a time until they can be removed by hand, then take off the connecting rod cap and bearing insert without dropping the insert. To protect the crankshaft journal and cylinder wall during piston removal, slip a short length of plastic or rubber hose over each connecting rod cap bolt. Remove the bearing insert and push the connecting rod/piston assembly out through the top of the engine using a wooden or plastic hammer handle, ensuring all ridge material has been cleared. Repeat this process for the remaining cylinders. After removal, reassemble the connecting rod caps and bearing inserts in their respective rods and install the cap nuts finger tight to prevent accidental damage to the bearing surfaces. Avoid separating the pistons from the connecting rods.