My Garage

My Account

Cart

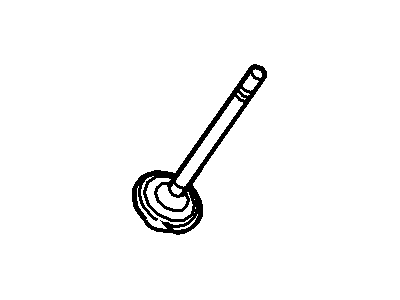

Genuine Ford Expedition Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Exhaust Valves found

Ford Expedition Exhaust Valve

Part Number: HL3Z-6505-D$27.47 MSRP: $41.07You Save: $13.60 (34%)Ships in 1-3 Business DaysFord Expedition Exhaust Valve

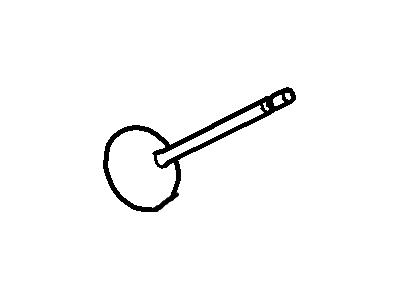

Part Number: 5L1Z-6505-B$17.31 MSRP: $25.30You Save: $7.99 (32%)Ships in 1-3 Business DaysFord Expedition Exhaust Valve

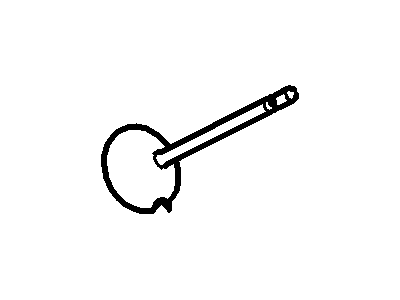

Part Number: 5L1Z-6505-BA$17.31 MSRP: $25.30You Save: $7.99 (32%)Ships in 1-3 Business DaysFord Expedition Exhaust Valve

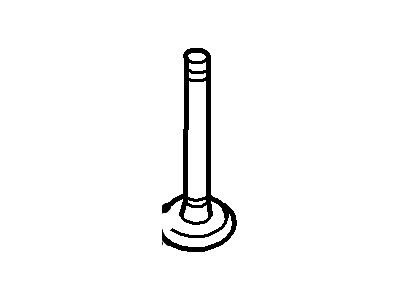

Part Number: AA5Z-6505-A$57.31 MSRP: $83.78You Save: $26.47 (32%)Ships in 1-3 Business Days

Ford Expedition Exhaust Valve

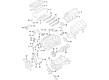

The Exhaust Valve in Ford Expedition vehicles fairly serves the purpose of internal combustion engine by releasing the burnt waste gas from the cylinders. It is also important to note that the it plays a huge and critical role when it comes to keeping the engine of the vehicles in their optimal performing and most efficient state. Broken or damaged Exhaust Valve has some effects including loss of power, another effect is that the engine may misfire or rough idle and another effect is that the fuel economy is affected. Different styles of Exhaust Valves have been used on Ford Expedition over the years and each has been made to improve the performance of the car's engine. While specific types are not detailed, the primary function remains consistent across these variations: to enable efficient management of exhaust flow and also for an engine to perform without many hitches. It is very important for the Ford Expedition as the Exhaust Valve is one of the components which directly affects the performance of the car.

We provide a wide range of Ford Expedition Exhaust Valve at the best prices possible. If you need Ford Expedition Exhaust Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Expedition Exhaust Valve Parts Questions & Experts Answers

- Q: Should servicing of valves, valve seats, and valve guides be done by a professional on Ford Expedition?A:Because of the work challenge and given the fact that the work requires the use of specialized tools and equipment, it is recommended that the main work of cutting and grinding of the valves, the seats and the guides as they are widely referred to as the 'valve job', should best be done by a professional. It is easier for a home mechanic to pull the head, preliminary wash and examine the head and then take the head to a dealer service department or an automotive machine shop for the real service to be done on it. Performing the inspection enables identification of the state of the head and valve train parts and be aware of required work and new parts when interacting with an automotive machine shop. The dealer service department or the automotive machine shop will perform the valve and spring removal, valve and valve seat reconditioning or replacement, valve guide reconditioning, valve spring, spring retainer, rotator and keeper inspection and replacement when necessary, valve seal replacement, reconstruction of valves and valve components, and determination of the installed spring height. Also the surface of the cylinder head gasket will be ground if it is warped. After the valve job is done by a professional the head turn out to be like new with no or with negligible wear possible. After removal, it must be cleaned for the second time and, before being put in place on the engine, a thorough removal of any metal chips and other abrasive particles resulting from the valve work or the honing of the head must be accomplished with the aid of compressed air to clear all the oil ways and holes.

Related Ford Expedition Parts

Browse by Year

2023 Exhaust Valve 2022 Exhaust Valve 2021 Exhaust Valve 2020 Exhaust Valve 2019 Exhaust Valve 2018 Exhaust Valve 2017 Exhaust Valve 2016 Exhaust Valve 2015 Exhaust Valve 2014 Exhaust Valve 2013 Exhaust Valve 2012 Exhaust Valve 2011 Exhaust Valve 2010 Exhaust Valve 2009 Exhaust Valve 2008 Exhaust Valve 2007 Exhaust Valve 2006 Exhaust Valve 2005 Exhaust Valve 2004 Exhaust Valve 2003 Exhaust Valve 2002 Exhaust Valve 2001 Exhaust Valve 2000 Exhaust Valve 1999 Exhaust Valve 1998 Exhaust Valve 1997 Exhaust Valve