My Garage

My Account

Cart

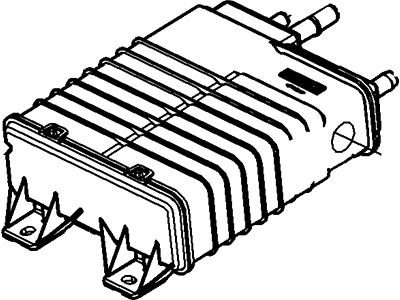

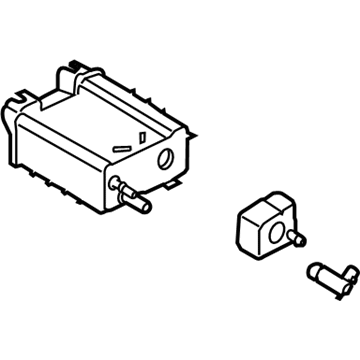

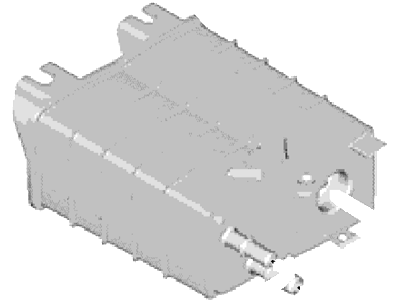

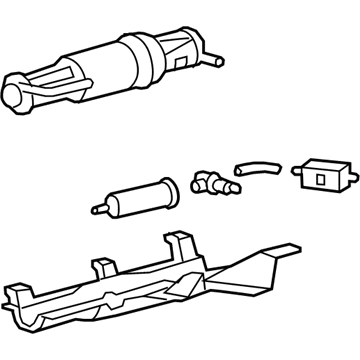

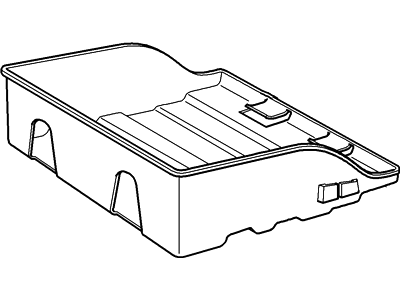

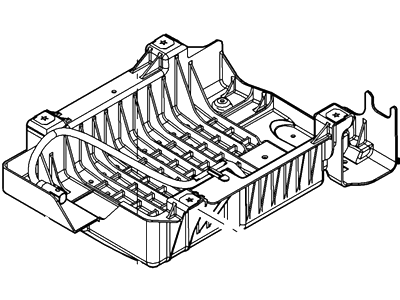

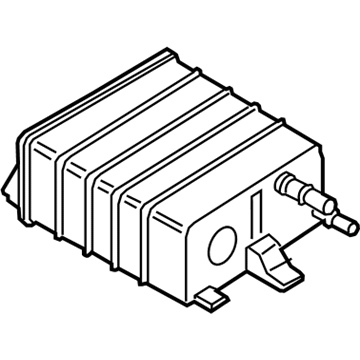

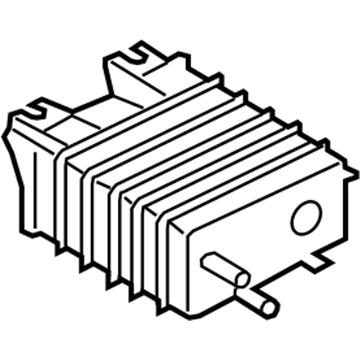

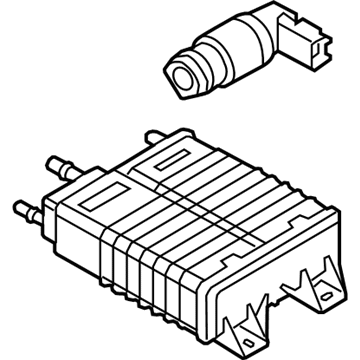

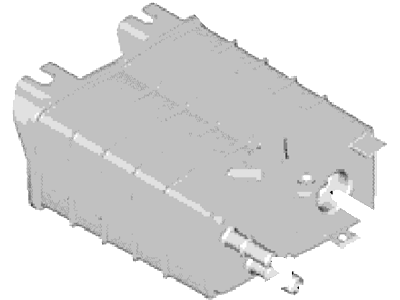

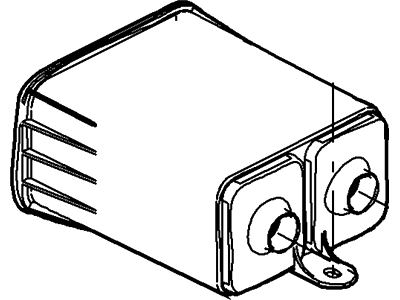

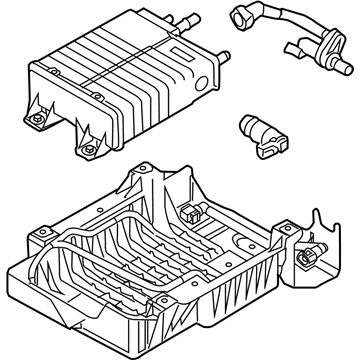

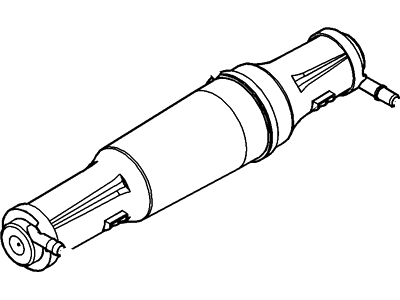

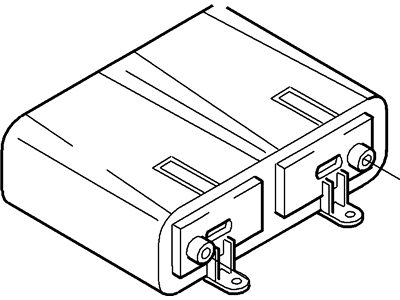

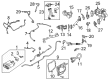

Genuine Ford Escape Vapor Canister

Fuel Vapor Canister- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

36 Vapor Canisters found

Ford Escape Fuel Vapour Store Cannister

Part Number: 9R3Z-9C985-C$219.09 MSRP: $365.45You Save: $146.36 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: HG9Z-9D653-A$291.70 MSRP: $498.00You Save: $206.30 (42%)Ford Escape Reservoir Assembly

Part Number: CU5Z-9D653-J$184.21 MSRP: $307.27You Save: $123.06 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: 5L8Z-9D653-BB$209.28 MSRP: $349.09You Save: $139.81 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: F6DZ-9D653-BA$162.80 MSRP: $269.09You Save: $106.29 (40%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Cannister

Part Number: CL8Z-9D653-A$226.72 MSRP: $378.18You Save: $151.46 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: GU5Z-9D653-C$178.92 MSRP: $305.45You Save: $126.53 (42%)Ships in 1-3 Business DaysFord Escape Reservoir Assembly

Part Number: GU5Z-9D653-A$184.21 MSRP: $307.27You Save: $123.06 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: 8R3Z-9D653-C$219.09 MSRP: $365.45You Save: $146.36 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: 9L8Z-9D653-B$219.09 MSRP: $365.45You Save: $146.36 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: CU5Z-9D653-A$184.21 MSRP: $307.27You Save: $123.06 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: F5AZ-9D653-A$69.32 MSRP: $116.91You Save: $47.59 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Cannister

Part Number: CM6Z-9D653-B$277.97 MSRP: $474.55You Save: $196.58 (42%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Cannister

Part Number: BL8Z-9D653-A$226.72 MSRP: $378.18You Save: $151.46 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: 5L8Z-9D653-BA$209.28 MSRP: $349.09You Save: $139.81 (41%)Ships in 1-2 Business DaysFord Escape Reservoir Assembly

Part Number: 7L8Z-9D653-C$209.28 MSRP: $349.09You Save: $139.81 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: 9L8Z-9D653-A$226.72 MSRP: $378.18You Save: $151.46 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: 9L8Z-9D653-C$226.72 MSRP: $378.18You Save: $151.46 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: LX6Z-9D653-F$251.79 MSRP: $420.00You Save: $168.21 (41%)Ships in 1-2 Business DaysFord Escape Fuel Vapour Store Cannister

Part Number: FG9Z-9D653-C$140.80 MSRP: $232.73You Save: $91.93 (40%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 36 Results

Ford Escape Vapor Canister

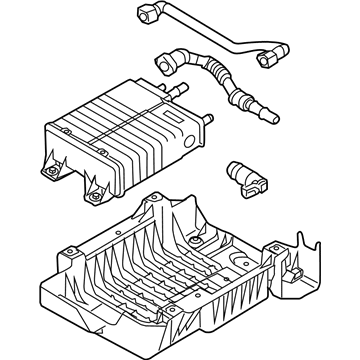

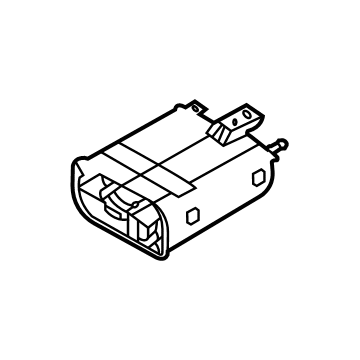

The Vapor Canister affixed to ford escape vehicles is part of the EVAP system purposed with maintaining the non-evaporation of hydrocarbons to the atmospher It works, by conserving fuel vapors from the fuel tank and supplying it into the engine at the required instances, where it is mixed with the air and fuel ratio for combustion. It is controlled by a purge valve that makes the release of the gas vapors to paves the way. Across the years there have been many instances where Vapor Canisters of Ford Escape models were implemented with more components that are changeable such as filters and other components including a canister vent solenoid and a fuel tank pressure sensor for additional diagnosis of the leakage. These advancements assist in making this system effective in its performance and also notify the driver of any future complications such as a loose fuel cap.

We provide a wide range of Ford Escape Vapor Canister at the best prices possible. If you need Ford Escape Vapor Canister, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Escape Vapor Canister Parts Questions & Experts Answers

- Q: What is the purpose and function of the Evaporative Emissions Control system,Canister Purge Valve,Fuel Pressure Sensor and Vapor Canister on Ford Escape?A:The Evaporative Emissions Control (EVAP) system is the system that is used to reduce the chance for fuel system emissions to evaporate and release unburned hydrocarbons into the atmosphere. During hot days, fumes in the fuel tank expand and when there is pressure build up, them is passed through the fuel vapor vent valve and the fuel vapor control valve to the EVAP canister where it is stored for some time until the engine can use it. The many elements of this system are installed underneath the vehicle; these are EVAP canister which is packed with activated charcoal, the check valve, dust separator and the canister vent solenoid. The fuel tank pressure sensor measures pressure inside the tank, and sends data to the PCM during leak tests. The fuel vapor vent valve regulates vapors that are to be admitted into the EVAP system while the fuel vapor control valve shuts off liquid fuel from entering the canister during fuelling. The canister vent solenoid is open most of the time and tests to seal the system and the EVAP check valve vents the air during refueling. The canister purge valve managed by the PCM controls the flow of the vapor into the intake manifold and its working is dependent on the manifold vacuum and the sensor. Some of the typical signs that indicate a defective-evaporative emission control system include foul smell of fuel, rough idle, and stalling, and in most cases, the hose connections and some of the components associated with the system are often checked for damages or leakage. To ensure that there is no increased fuel vapor pressure then the gas cap should be disconnected so that pressure can be heard to be escaping. Component replacement entails a step of disconnecting the battery and when replacing particular components, there is need to remove them and replace them with the right part and reconnection of the PCM for better performance.

Related Ford Escape Parts

Browse by Year

2023 Vapor Canister 2022 Vapor Canister 2021 Vapor Canister 2020 Vapor Canister 2019 Vapor Canister 2018 Vapor Canister 2017 Vapor Canister 2016 Vapor Canister 2015 Vapor Canister 2014 Vapor Canister 2013 Vapor Canister 2012 Vapor Canister 2011 Vapor Canister 2010 Vapor Canister 2009 Vapor Canister 2008 Vapor Canister 2007 Vapor Canister 2006 Vapor Canister 2005 Vapor Canister 2004 Vapor Canister 2003 Vapor Canister 2002 Vapor Canister 2001 Vapor Canister