My Garage

My Account

Cart

Genuine Ford Crown Victoria Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Oil Pans found

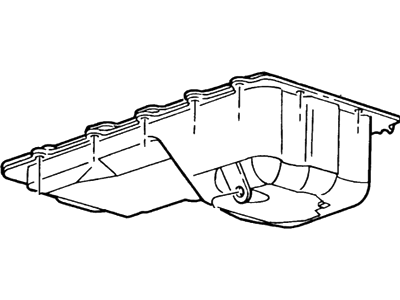

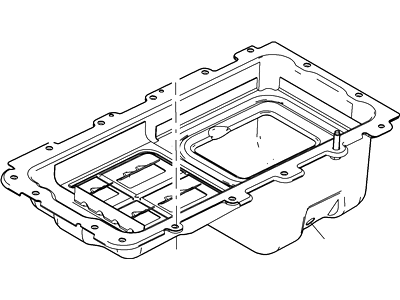

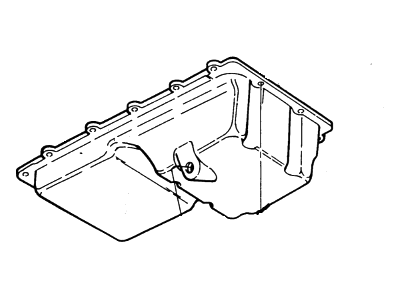

Ford Crown Victoria Engine Oil Pan Assembly

Part Number: XL3Z-6675-AA$74.87 MSRP: $102.30You Save: $27.43 (27%)Ships in 1-2 Business DaysFord Crown Victoria Engine Oil Pan Assembly

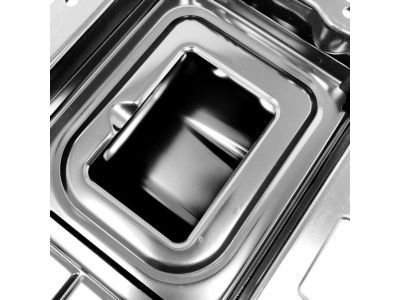

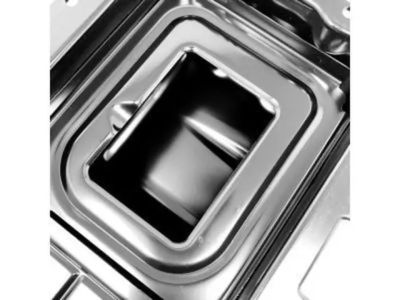

Part Number: 3W7Z-6675-BC$87.40 MSRP: $127.78You Save: $40.38 (32%)Ford Crown Victoria Engine Oil Pan Assembly

Part Number: 3W7Z-6675-BB$87.40 MSRP: $127.78You Save: $40.38 (32%)Ships in 1-3 Business DaysFord Crown Victoria Engine Oil Pan Assembly

Part Number: F8AZ-6675-AA$74.87 MSRP: $102.30You Save: $27.43 (27%)

Ford Crown Victoria Oil Pan

Oil Pan in Ford Crown Victoria automobiles is an auxiliary tank for storage of engine oil in order to afford proper protection and cooling of the automobile's internal parts. The Oil Pan also implements a wet sump system in which oil that passes through the pickup tube where an oil pump draws it circulates it into the engine and returns it to the Oil Pan. This design is crucial when regulating oil levels when the vehicle is at various working conditions. Ford Crown Victoria oil pans back in the day used stamped steel in most of its models but in their current models the use of cast aluminum is common in most engine models. The change in the materials applied have therefore been deemed as evolution of this basic function in response to enhancements in durability and efficiency. In a nutshell, the Oil Pan plays a critical role in the Ford Crown Victoria's engine, protecting it from oil loss and guaranteeing productivity.

We provide a wide range of Ford Crown Victoria Oil Pan at the best prices possible. If you need Ford Crown Victoria Oil Pan, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Crown Victoria Oil Pan Parts Questions & Experts Answers

- Q: How to remove and install the oil pan in 5.0L V8 engine on Ford Crown Victoria?A:Relieve the fuel system pressure and disconnect the negative battery cable from the battery. Remove the air cleaner assembly and the fan shroud mounting bolts, positioning the shroud back over the fan. Remove the oil level dipstick and disconnect the oil level sensor switch on the side of the oil pan if equipped. If applicable, remove the screws attaching the vacuum solenoids to the firewall behind the engine and position them out of the way without disconnecting. Disconnect and lower the exhaust crossover pipe from the manifolds, then carefully unbolt the exhaust pipe-to-catalytic converter connection and remove the exhaust pipe section. Drain the engine oil and remove the oil filter, ensuring to drain oil from both plugs if the vehicle has a dual-sump pan. Disconnect the shift linkage from the body to the transmission and the transmission cooler lines at the radiator. Remove the four torque converter cover retaining bolts and detach the cover, then remove the starter motor and disconnect the fuel lines. Disconnect the steering flex coupling and remove the two bolts attaching the steering gear to the subframe, allowing the steering gear to rest on the subframe away from the oil pan. Loosen the nuts holding the transmission mount to the crossmember without removing them completely, then remove the through bolts from the front Engine Mounts. Place a block of wood under the oil pan and lift the engine slightly with a jack, being cautious of the clearance between the transmission dipstick tube and the Thermactor downstream air tube. Place wooden blocks between the mounts and subframe, then remove the oil pan mounting bolts, noting that reinforcement strips may come loose. Carefully separate the pan from the block without prying, using a large rubber mallet or a block of wood and a hammer instead. Remove the oil pump pickup tube fasteners and allow the pickup to drop into the oil pan, ensuring the pan can be removed. Rotate the crankshaft as needed for clearance and remove the oil pan from the vehicle. For installation, remove the gasket(s) using a gasket scraper or putty knife, ensuring all traces of old gasket material and sealant are removed from the pan and block. Clean the mating surfaces and check the oil pan flange for distortion, flattening it if necessary. For four-piece style gaskets, remove old rubber seals from the rear main bearing cap and timing chain cover, clean the grooves, and install new seals with RTV sealant or gasket contact adhesive. Install the oil pump pickup tube along with the pan, tightening the pickup tube bolts to the specified torque. Position the pan against the block and install the bolts finger tight, ensuring the seal(s) and gasket(s) haven't shifted, then tighten the bolts in three steps to the specified torque, starting at the center and working outward in a spiral pattern. The remaining steps are the reverse of removal, and remember to refill the engine with oil and replace the filter before starting it, then check for oil leaks at the oil pan.