My Garage

My Account

Cart

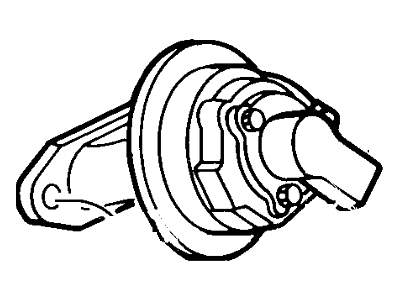

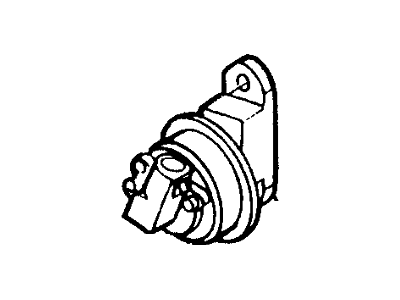

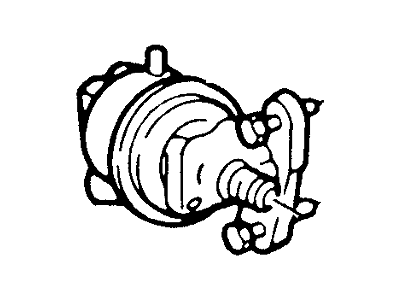

Genuine Mercury Capri EGR Valve

Emissions EGR Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 EGR Valves found

Mercury Capri EGR Valve

We provide a wide range of Mercury Capri EGR Valve at the best prices possible. If you need Mercury Capri EGR Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

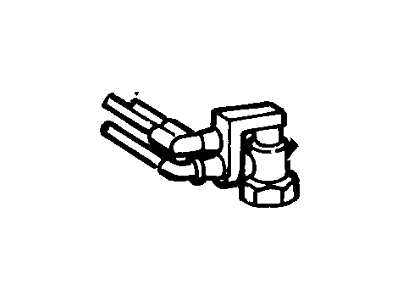

Mercury Capri EGR Valve Parts Questions & Experts Answers

- Q: How Does the EGR System Operate, and How to Test and Replace EGR Valves on Mercury Capri?A:The EGA system is aimed at recirculating a small portion of the exhaust gases in the combustion cycle in order to cut the creation of NOx emissions, with the amount and the timing of the ensuing re-circulation prescripts by parameters like engine speed, altitude, manifold vacuum, exhaust system back-pressure, coolant temperature, and the throttle angle. EGR valves, which are vacuum actuated, include three types: They are the ported valve the integral back pressure valve and the last and most complex type is the electronic type. The ported EGR valve works with a vacuum signal from the EGR port and using the position of the tapered pintle or poppet controls the flow. The integral backpressure transducer valve uses backpressure and EGR ported vacuum together, and both are necessary , and is available in a poppet style as well as tapered pintle. The EEC-IV system uses an electronic EGR valve; the flow is monitored by an EGR Valve Position Sensor, and the operation is controlled by an EGR solenoid or an electronic vacuum regulator. For checking the ported valve following should be done: The vacuum line should be in correct position and in good health; there should be no vacuum at the curb idle; there should be vacuum at 3000 rpm. If there is any doubt that the valve might have a leak then a blocking gasket test could be done. For the integral backpressure transducer valve guarantee vacuums lines are well fitted and check on its operation under vacuum, and lack of vacuum at idle position and when cold. If sticking is suspected, the valve should be cycled manually It is also recommended that the manual cycling be done slowly to avoid laden stresses. The electronic valve should be inspected for hose condition and cleanliness of the port where there is leakage test done on it with the aid of a vacuum pump. If the above are not met, the EGR valve, the O-ring or EVP may have to be replaced. For EGR valve replacement, remove the battery cable, disconnect the electrical connector for electric valves, remove the EGR pipe fitting, and unbolt the valve-clean all gasket surfaces and reassemble the new valve in a reverse fashion.