My Garage

My Account

Cart

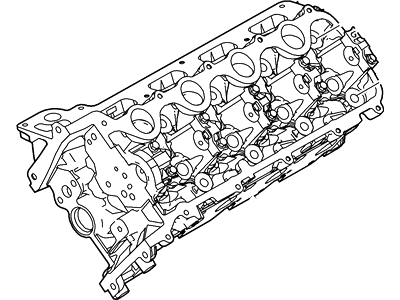

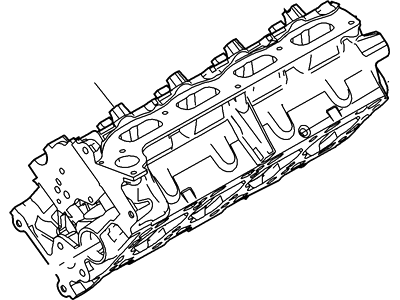

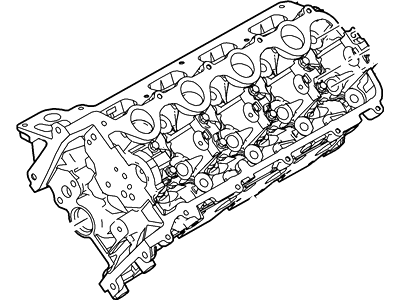

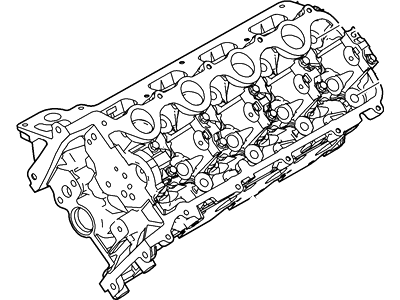

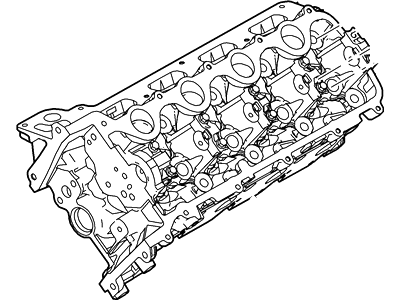

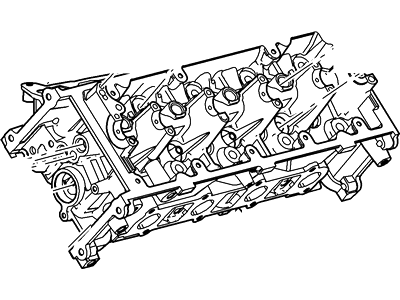

Genuine Lincoln Navigator Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Cylinder Heads found

Lincoln Navigator Cylinder Head Assembly

Part Number: 9L3Z-6049-H$885.57 MSRP: $1209.23You Save: $323.66 (27%)Ships in 1-3 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: HL3Z-6049-J$1750.21 MSRP: $2396.92You Save: $646.71 (27%)Ships in 1-3 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: 9L3Z-6049-GB$275.03 MSRP: $371.67You Save: $96.64 (26%)Ships in 1-2 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: 9L3Z-6049-E$2890.50 MSRP: $4247.69You Save: $1357.19 (32%)Ships in 1-3 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: DL3Z-6049-A$1141.61 MSRP: $1641.54You Save: $499.93 (31%)Ships in 1-2 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: 8L3Z-6049-B$275.03 MSRP: $371.67You Save: $96.64 (26%)Ships in 1-2 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: HL3Z-6049-L$1815.17 MSRP: $2486.15You Save: $670.98 (27%)Ships in 1-3 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: 9L3Z-6049-C$1930.90 MSRP: $4247.69You Save: $2316.79 (55%)Ships in 1-2 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: NL3Z-6049-C$766.08 MSRP: $1052.31You Save: $286.23 (28%)Ships in 1-2 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: NL3Z-6049-D$1643.81 MSRP: $2250.77You Save: $606.96 (27%)Ships in 1-2 Business DaysLincoln Navigator Cylinder Head Assembly

Part Number: HL3Z-6049-A$1750.21 MSRP: $2396.92You Save: $646.71 (27%)Lincoln Navigator Cylinder Head Assembly

Part Number: HL3Z-6049-B$1815.17 MSRP: $2486.15You Save: $670.98 (27%)

| Page 1 of 2 |Next >

1-20 of 31 Results

Lincoln Navigator Cylinder Head

We provide a wide range of Lincoln Navigator Cylinder Head at the best prices possible. If you need Lincoln Navigator Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln Navigator Cylinder Head Parts Questions & Experts Answers

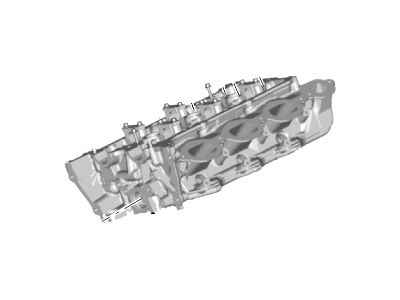

- Q: What precautions should be taken when removing and installing cylinder heads in V6 engine on Lincoln Navigator?A:The cylinder heads should not be removed until the engine has cooled, or warpage of components will occur. First, remove the battery cable negative terminal, and eliminate the valve covers, pushrods, and Rocker Arms. After that, remove the upper intake plenum and lower Intake Manifold as well as loosening the Exhaust Manifold of the head scheduled for removal. For the left cylinder head, remove the power steering reservoir with the hoses still connected, and the drivebelts, and the air-conditioning compressor/power- steering pump bracket. For the right cylinder head, unplug the alterner wiring and remove the bolts but keep the alterner bracket on if possible. The cylinder head bolts should be loosened at intervals of two clockwise, and untightened in counter clockwise sequence to ease their total removal; the old bolts are discarded and it is also important to remove wire harness bolts at back heads of the head. Remove the cylinder heads gently off the engine by putting a piece of wooden block under it and apply a hammer gently if required, and then place the cylinder heads on wooden blocks so that there is no further damage. Make sure the mating surfaces on the cylinder heads and engine block are free of contaminants before assembly, you provide gasket scraper and solvent to clean them. One should look for signs of damage on the surfaces and use a tap to remove debris in the bolt holes. Align the new gasket and place it over the dowel pins; subsequently, install the cylinder heads over the engine block without shifting the gasket. Treat the threads of new cylinder head bolts with a little oil before fitting them, then tighten them only with your fingers until they are firm and using the correct torque sequence without removing them all at one time. The rest of installation procedure is executed oppositely to the removal process, after the installation is completed change the engine oil and filter before start the engine and check the leaks.

Related Lincoln Navigator Parts

Browse by Year

2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head