My Garage

My Account

Cart

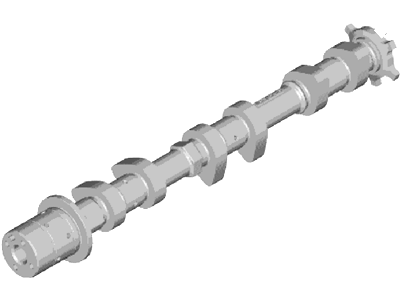

Genuine Lincoln Navigator Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Camshafts found

Lincoln Navigator Camshaft

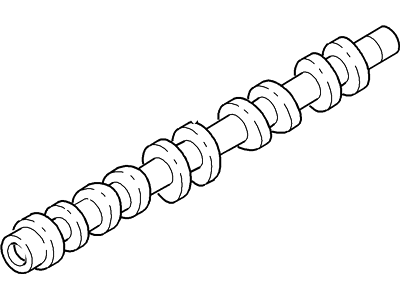

Part Number: 5L1Z-6250-AA$259.86 MSRP: $406.67You Save: $146.81 (37%)Ships in 1-3 Business DaysLincoln Navigator Camshaft

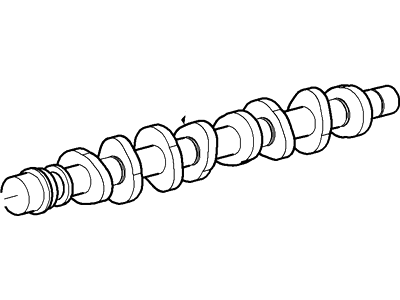

Part Number: BL3Z-6250-D$143.64 MSRP: $210.00You Save: $66.36 (32%)Ships in 1-2 Business DaysLincoln Navigator Camshaft

Part Number: 9L3Z-6250-A$152.76 MSRP: $223.33You Save: $70.57 (32%)Ships in 1-2 Business DaysLincoln Navigator Camshaft

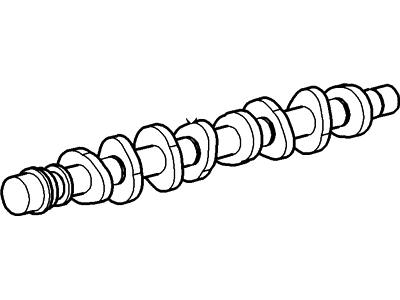

Part Number: DL3Z-6250-AB$99.07 MSRP: $144.83You Save: $45.76 (32%)Ships in 1-3 Business DaysLincoln Navigator Camshaft

Part Number: YF3Z-6250-AA$577.89 MSRP: $921.67You Save: $343.78 (38%)Ships in 1-2 Business DaysLincoln Navigator Bolt

Part Number: ML3Z-6279-A$3.99 MSRP: $5.68You Save: $1.69 (30%)Ships in 1-2 Business DaysLincoln Navigator Camshaft

Part Number: BL3Z-6250-J$86.18 MSRP: $126.00You Save: $39.82 (32%)Ships in 1-3 Business DaysLincoln Navigator Camshaft

Part Number: HL3Z-6250-L$110.58 MSRP: $161.67You Save: $51.09 (32%)Ships in 1-3 Business DaysLincoln Navigator Camshaft

Part Number: YL7Z-6250-AA$716.04 MSRP: $1105.00You Save: $388.96 (36%)Ships in 1-2 Business DaysLincoln Navigator Camshaft

Part Number: YF3Z-6250-DA$851.80 MSRP: $1314.50You Save: $462.70 (36%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 22 Results

Lincoln Navigator Camshaft

A camshaft, used in Lincoln Navigator vehicles, regulates the opening and closing of intake and exhaust valves to allow the mixture of air and fuel to enter into the combustion chamber as well as the removal of exhaust products. Most made up of iron or steel, the Lincoln Navigator camshaft functions through Operations Head Value, Single Head Cam, and Double Head Camformation, all of which affects performance in different ways. Lift, duration and lobe separation angle of camshaft are important factors which are used to determine power output as well as idle quality. Performance camshafts are beneficial for improving the supply of fresh air and horsepower, especially at the higher rpms, and s give the opportunity to accomplish customized alterations. In general, Lincoln Navigator camshaft is very vital for the alteration of valves and piston in linear motion and therefore greatly influences the overall performance of the car.

We provide a wide range of Lincoln Navigator Camshaft at the best prices possible. If you need Lincoln Navigator Camshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln Navigator Camshaft Parts Questions & Experts Answers

- Q: How do you remove and install Camshaft Bearing and Camshaft in V6 engine on Lincoln Navigator?A:To inspect camshaft lobe lift and measure wear, it is required to have the Rocker Arms out of the way while the pushrods remain in. Turn the engine until the number one piston is at top dead centre of the compression stroke: install a dial indicator on the cylinder head with its plunger touching the first rocker arm. Aim the needle of the dial indicator at the lowest point of the cam lobe and zero it and slowly turn the crankshaft until the needle deflects in the opposite direction, this gives the maximum cam lobe lift. Note this measurement and move the piston to TDC then follow the same process on the other valves while making sure that every piston is at TDC. After making the above checks, another check can be made to compare it with the specified value; if the lobe lift is below the specified value then cam lobe wear has taken place and this is a sign that you are going to need a new camshaft. For removal, pull out the pushrods and their lifters, Timing Chain and the sprocket from the camshaft; measure the end play with a dial indicator. In case the play is beyond the measures allowed by the specifications, it is advisable to fit a new thrust plate when installing the new assembly. Withdraw the camshaft slowly, gently to prevent bending the bearings that are sometimes so small that they can hardly be seen. You should check the camshaft for wear, pitting or any form of damage once it has been removed; if the journals are badly worn, both the camshaft and bearings will have to be taken out and this will call for the services of an expert. Check the bearing journals for signs of wear by using a micrometer and examine the lobes for any sign of discoloration or damage, if the camshaft has not been badly abused, it may be reused. The procedure for the balance shaft is similar to the one described above; the thrust plate bolts should be loosened, and the shaft should be guided out; still, it is necessary to remember that any signs of wearing of the bearings might only be seen by a machine shop. The journals ought to be lubricated any time installation is being performed again and the keyway should sit right as it should with the gear. It is also recommended that the camshaft bearing journals and lobes should be lubricated before placing the camshaft into the engine; also aligning the balance shaft gear. Coat the thrust plate with grease and while doing this place it in its proper position, To put it in the right place for reassembly the process is done in the reverse to that of the removal process. Last but not the least; replace the oil as well as oil filter before turning on the engine.

Related Lincoln Navigator Parts

Browse by Year

2023 Camshaft 2022 Camshaft 2021 Camshaft 2020 Camshaft 2019 Camshaft 2018 Camshaft 2017 Camshaft 2016 Camshaft 2015 Camshaft 2014 Camshaft 2013 Camshaft 2012 Camshaft 2011 Camshaft 2010 Camshaft 2009 Camshaft 2008 Camshaft 2007 Camshaft 2006 Camshaft 2005 Camshaft 2004 Camshaft 2003 Camshaft 2002 Camshaft 2001 Camshaft 2000 Camshaft 1999 Camshaft 1998 Camshaft