My Garage

My Account

Cart

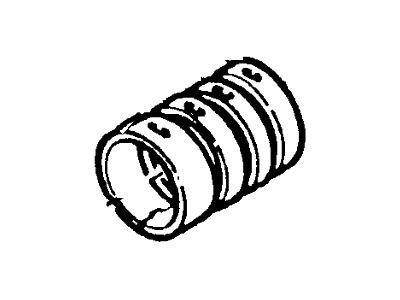

Genuine Ford Ranger Camshaft Bearing

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Camshaft Bearings found

| Page 1 of 2 |Next >

1-20 of 23 Results

Ford Ranger Camshaft Bearing

We provide a wide range of Ford Ranger Camshaft Bearing at the best prices possible. If you need Ford Ranger Camshaft Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Ranger Camshaft Bearing Parts Questions & Experts Answers

- Q: How to inspect and replace camshaft and Camshaft Bearing on 1993-2011 Ford Ranger?A:To inspect the camshaft, measure the major and minor diameters of each cam lobe to determine the lobe lift, and if it is 0.005-inch less than specified, replace the camshaft and all lifters or followers. After removing the camshaft, clean it with solvent and inspect the bearing journals for uneven wear, pitting, or signs of seizure; if damaged, both the camshaft and bearings need replacement. Measure the camshaft bearing journals with a micrometer, and if they are more than 0.001-inch out-of-round, replace the camshaft. Check the camshaft lobes for heat discoloration, scoring, chipping, pitting, and uneven wear; if they are in good condition and the lobe lift measurements are as specified, the camshaft can be reused. For lifter inspection, clean the lifters thoroughly and ensure the roller on each turns freely without wear, checking the pushrod seat for wear and fit in the original bore. Press down on the plunger to confirm it operates freely; if lifters show wear or binding, replace them as a complete set along with the camshaft. When installing new lifters, a new camshaft must also be installed, and used lifters should only be installed with the original camshaft in their original locations. Camshaft bearing replacement requires special tools and expertise, so it is advisable to take the block or head to an automotive machine shop for proper handling.

Related Ford Ranger Parts

Browse by Year

2008 Camshaft Bearing 2007 Camshaft Bearing 2006 Camshaft Bearing 2005 Camshaft Bearing 2004 Camshaft Bearing 2003 Camshaft Bearing 2002 Camshaft Bearing 2001 Camshaft Bearing 2000 Camshaft Bearing 1999 Camshaft Bearing 1998 Camshaft Bearing 1997 Camshaft Bearing 1996 Camshaft Bearing 1995 Camshaft Bearing 1994 Camshaft Bearing 1993 Camshaft Bearing 1992 Camshaft Bearing 1991 Camshaft Bearing 1990 Camshaft Bearing 1989 Camshaft Bearing 1988 Camshaft Bearing 1987 Camshaft Bearing 1986 Camshaft Bearing 1985 Camshaft Bearing 1984 Camshaft Bearing 1983 Camshaft Bearing