My Garage

My Account

Cart

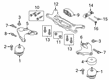

Genuine Ford Mustang Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

99 Engine Mounts found

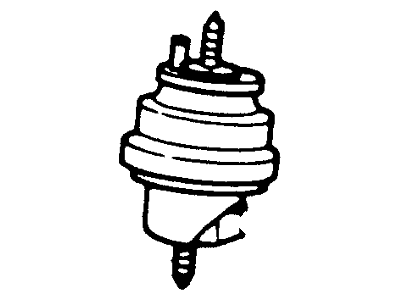

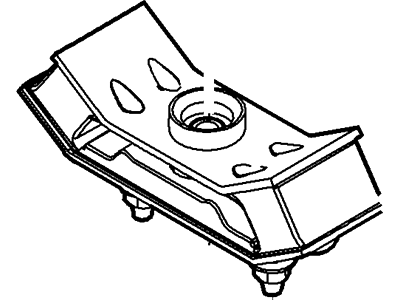

Ford Mustang Insulator Assembly

Part Number: FR3Z-6038-D$88.81 MSRP: $134.57You Save: $45.76 (34%)Ships in 1-3 Business DaysFord Mustang Transmission Mount

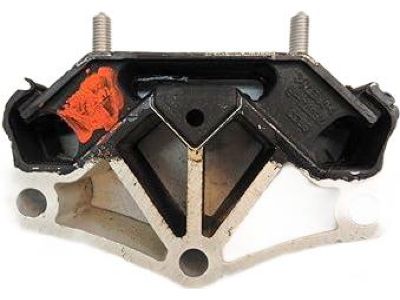

Part Number: 1R3Z-6068-AA$68.17 MSRP: $94.70You Save: $26.53 (29%)Ships in 1-2 Business DaysFord Mustang Engine Support Insulator Assembly

Part Number: FR3Z-6038-H$211.31 MSRP: $311.67You Save: $100.36 (33%)Ford Mustang Engine Mounting Bracket

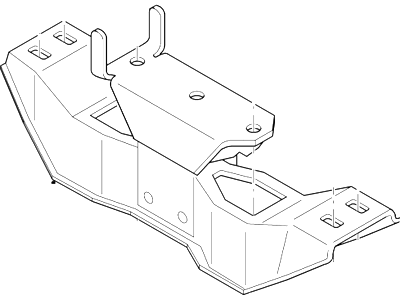

Part Number: BR3Z-6031-A$74.78 MSRP: $109.33You Save: $34.55 (32%)Ships in 1-3 Business Days

Ford Mustang BRACKET - ENGINE MOUNTING

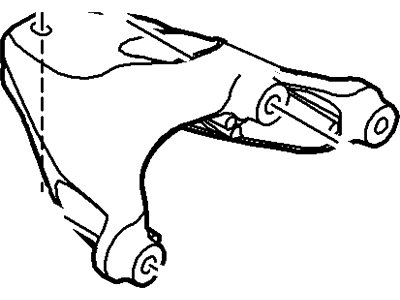

Part Number: BR3Z-6031-C$83.28 MSRP: $108.35You Save: $25.07 (24%)Ships in 1-3 Business DaysFord Mustang Engine Front Support Bracket

Part Number: BR3Z-6028-A$67.84 MSRP: $99.18You Save: $31.34 (32%)Ships in 1-3 Business DaysFord Mustang Transmission Mount

Part Number: 2R3Z-6068-FJ$68.17 MSRP: $94.70You Save: $26.53 (29%)Ships in 1-2 Business DaysFord Mustang Engine Support Insulator Assembly

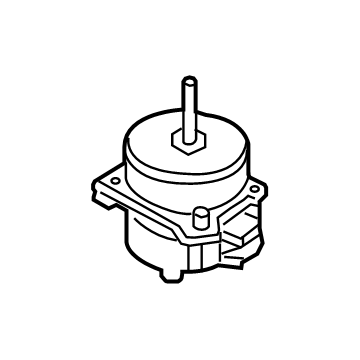

Part Number: 8R3Z-6068-D$99.05 MSRP: $135.34You Save: $36.29 (27%)Ships in 1-2 Business DaysFord Mustang Damper Assembly

Part Number: JR3Z-4A085-B$110.43 MSRP: $185.17You Save: $74.74 (41%)Ships in 1-3 Business DaysFord Mustang Damper Assembly

Part Number: FR3Z-6F028-A$90.36 MSRP: $139.70You Save: $49.34 (36%)Ships in 1-3 Business DaysFord Mustang Insulator Assembly Engine S

Part Number: E83Z6068BA$64.89 MSRP: $88.67You Save: $23.78 (27%)Ships in 1-2 Business DaysFord Mustang BRACKET - ENGINE MOUNTING

Part Number: FR3Z-6031-B$92.56 MSRP: $144.83You Save: $52.27 (37%)Ships in 1-2 Business Days

| Page 1 of 5 |Next >

1-20 of 99 Results

Ford Mustang Engine Mount

We provide a wide range of Ford Mustang Engine Mount at the best prices possible. If you need Ford Mustang Engine Mount, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Engine Mount Parts Questions & Experts Answers

- Q: How should engine mounts be checked and replaced in V6 engine on Ford Mustang?A:A car's engine mounts do not really need regular servicing but there is need to replace or repair any broken or deteriorated ones as soon as possible so as not to affect other parts of the driveline. Normal check on the mounts also requires that the engine be lifted slightly off its full weight on the mounts. First of all, lift and safely support the car on jack stands; then place a jack beneath the Oil Pan under the engine; taking a piece of wood and place it between the head of the jack and the oil pan and slowly raise the engine up enough to relieve some pressure off the mounts. Thus, it is unnecessary to put any part of the body under the engine when it is only lifted with the help of a jack. Sometimes, if the jack and wood would allow the automobile to sit beneath, then lifting of the car may not be required. Look for areas that may have cracks or areas of rubber that have become hard, a fact one should bear in mind is that such splits may run down the middle of the mount. As an assistant should try to lift the jack to check whether the upper part of the mount separates from the lower part; if yes then the mount is to be replaced. Use a large screwdriver or pry bar to employ force and see if the mount plates are moving relatively to the engine or the frame. If you see movement go back down and snug up the mount bolts. To remove the mount, you pull the cable on the negative terminal of the battery, unclasp the air intake duct that is connected to the throttle body and if replacing the left side mount, the air filter housing should be removed for ease of access. Take off the throttle body and also the bolt wherein the accessory bracket is placed at the front of the left cylinder head. For the engine support fixture or hoist, there should be a chain provided and with that chain you should have used the removed bolt to fix it into place and make sure it is properly anchored and tight. Another method is to use a floor jack along with a piece of wood under the oil pan At the same time it is necessary to take care that the legs of the engine support fixture do not rest on the fenders-they should be placed on the nearest body part to the suspension strut tower . Screw the mount off the mount bracket and chassis, unscrew the mount bracket from the engine and finally screw the mount off. Disassembly starts from the outer end of the wire harness and installation also does the reverse starting with the mount fasteners which is then tightened to torque specified to lock into action a thread-locking compound.

Related Ford Mustang Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount 2000 Engine Mount 1999 Engine Mount 1998 Engine Mount 1997 Engine Mount 1996 Engine Mount 1995 Engine Mount 1994 Engine Mount 1993 Engine Mount 1992 Engine Mount 1991 Engine Mount 1990 Engine Mount 1989 Engine Mount 1988 Engine Mount 1987 Engine Mount 1986 Engine Mount 1985 Engine Mount 1984 Engine Mount 1983 Engine Mount 1981 Engine Mount 1980 Engine Mount