My Garage

My Account

Cart

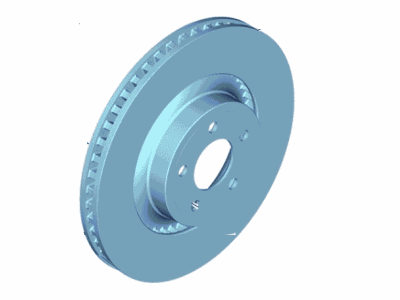

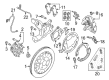

Genuine Ford Mustang Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

76 Brake Discs found

Ford Mustang Brake Rotor Assembly

Part Number: KR3Z-1125-J$127.95 MSRP: $190.00You Save: $62.05 (33%)

Ford Mustang Brake Rotor Assembly

Part Number: KR3Z-1125-G$123.46 MSRP: $183.33You Save: $59.87 (33%)Ships in 1-3 Business DaysFord Mustang Brake Rotor Assembly

Part Number: G2MZ-1V125-ACA$39.28 MSRP: $53.68You Save: $14.40 (27%)Ships in 1-2 Business DaysFord Mustang Brake Rotor Assembly

Part Number: F8ZZ-2C026-AA$70.06 MSRP: $108.32You Save: $38.26 (36%)Ford Mustang Brake Rotor Assembly

Part Number: F4ZZ-2C026-A$70.06 MSRP: $108.32You Save: $38.26 (36%)Ford Mustang Rotor Assembly

Part Number: 5U2Z-1V125-T$76.99 MSRP: $116.65You Save: $39.66 (34%)Ships in 1 Business DayFord Mustang Brake Rotor Assembly

Part Number: GR3Z-2C026-C$104.61 MSRP: $158.50You Save: $53.89 (34%)Ships in 1 Business Day

Ford Mustang Brake Rotor Assembly

Part Number: KR3Z-1125-H$108.13 MSRP: $163.83You Save: $55.70 (34%)Ships in 1-3 Business DaysFord Mustang Rotor Assembly

Part Number: 7R3Z-1125-A$110.00 MSRP: $166.67You Save: $56.67 (34%)Ships in 1-2 Business Days

Ford Mustang Brake Rotor Assembly

Part Number: GR3Z-2C026-E$99.50 MSRP: $153.83You Save: $54.33 (36%)Ford Mustang Brake Rotor Assembly

Part Number: DR3Z-2C026-A$87.99 MSRP: $133.32You Save: $45.33 (34%)Ford Mustang Rotor Assembly

Part Number: DR3Z-1125-C$121.00 MSRP: $183.33You Save: $62.33 (34%)Ships in 1-2 Business DaysFord Mustang Rotor Assembly

Part Number: 4R3Z-1125-BA$121.00 MSRP: $183.33You Save: $62.33 (34%)Ships in 1-2 Business DaysFord Mustang Brake Rotor Assembly

Part Number: GR3Z-2C026-D$99.50 MSRP: $153.83You Save: $54.33 (36%)Ships in 1-2 Business DaysFord Mustang Brake Rotor Assembly

Part Number: FR3Z-2C026-A$104.61 MSRP: $158.50You Save: $53.89 (34%)Ships in 1 Business DayFord Mustang Brake Rotor Assembly

Part Number: G2MZ-1V125-BLA$99.07 MSRP: $167.09You Save: $68.02 (41%)Ships in 1-2 Business DaysFord Mustang Brake Rotor Assembly

Part Number: G2MZ-1V125-BYA$96.14 MSRP: $158.91You Save: $62.77 (40%)Ships in 1-2 Business DaysFord Mustang Brake Rotor Assembly

Part Number: GR3Z-2C026-B$99.50 MSRP: $153.83You Save: $54.33 (36%)Ships in 1-2 Business Days

| Page 1 of 4 |Next >

1-20 of 76 Results

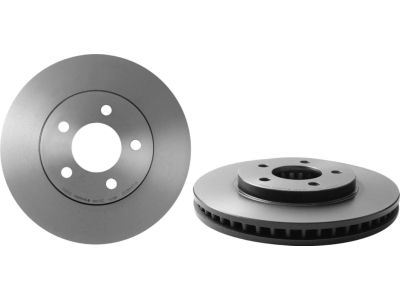

Ford Mustang Brake Disc

Brake Disc is located in the disc brake system of Ford Mustang vehicles which enable brake pads to abrade and degree of slowing or stopping the vehicles. The rotor is fitted to the axle or hub where it spins with the wheel and when the brakes are applied hydraulic pressure is used force the calipers to pinch the pads against the rotor. This design provides better cooling as compared to the drum brakes especial when used with the vented rotos which have cooling ribs. In Mustang models, diverse kinds of Brake Discs have been used such as the solid and the vented types. A solid rotor is used mainly on non-performance class models while a vented rotor is used on the performance models thus enhancing heat dispersion. Option like drilled or slotted rotors boost the performance by minimizing heat and noise but they cause higher rates of pad wear. It is very important to keep the rotors squeaky clean and; in cases where they are worn or damaged, then ought to be replaced as soon as possible.

We provide a wide range of Ford Mustang Brake Disc at the best prices possible. If you need Ford Mustang Brake Disc, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Brake Disc Parts Questions & Experts Answers

- Q: How to inspect and refinish brake discs on a Ford Mustang?A:The manufacturer recommends using a specialized brake lathe to refinish brake discs while they are still installed on the vehicle. To inspect the discs, start by loosening the wheel lug nuts and raising the vehicle on jackstands. Remove the Brake Caliper and suspend it out of the way with wire. Reinstall the lug nuts to hold the disc against the hub and visually check for any score marks, cracks, or other damage. Deep score marks or cracks may require disc refinishing or replacement. To check disc runout, use a dial indicator and turn the disc. An indicator reading exceeding 0.003-inch may cause pulsation and require disc refinishing or replacement. The disc thickness should not be machined below the specified minimum refinish thickness, which can be checked with a micrometer. To remove and install the disc, remove the caliper mounting bracket and mark the disc in relation to the hub before removing it. Clean the hub flange and inside of the disc before installing it onto the hub assembly. Install the caliper onto the mounting bracket and tighten the bolts. Lower the vehicle, tighten the wheel lug nuts, and depress the brake pedal to bring the pads into contact with the disc. Check the brake operation before using the vehicle normally.

Related Ford Mustang Parts

Browse by Year

2024 Brake Disc 2023 Brake Disc 2022 Brake Disc 2021 Brake Disc 2020 Brake Disc 2019 Brake Disc 2018 Brake Disc 2017 Brake Disc 2016 Brake Disc 2015 Brake Disc 2014 Brake Disc 2013 Brake Disc 2012 Brake Disc 2011 Brake Disc 2010 Brake Disc 2009 Brake Disc 2008 Brake Disc 2007 Brake Disc 2006 Brake Disc 2005 Brake Disc 2004 Brake Disc 2003 Brake Disc 2002 Brake Disc 2001 Brake Disc 2000 Brake Disc 1999 Brake Disc 1998 Brake Disc 1997 Brake Disc 1996 Brake Disc 1995 Brake Disc 1994 Brake Disc 1993 Brake Disc 1992 Brake Disc 1991 Brake Disc 1990 Brake Disc 1989 Brake Disc 1988 Brake Disc 1987 Brake Disc 1986 Brake Disc 1985 Brake Disc 1984 Brake Disc 1983 Brake Disc 1982 Brake Disc