My Garage

My Account

Cart

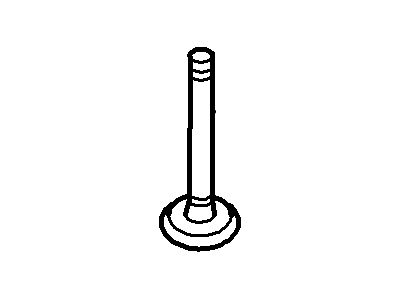

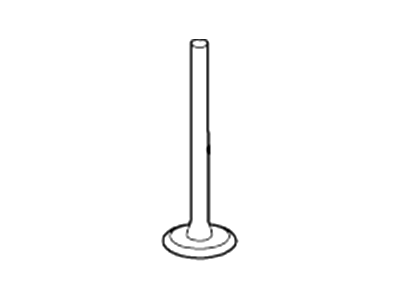

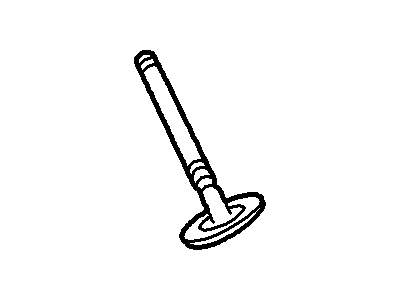

Genuine Ford Fusion Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Intake Valves found

Ford Fusion Inlet Valve

Part Number: 7T4Z-6507-B$18.28 MSRP: $26.03You Save: $7.75 (30%)Ships in 1-3 Business DaysFord Fusion Inlet Valve

Part Number: AL8Z-6507-A$26.08 MSRP: $38.13You Save: $12.05 (32%)Ships in 1-2 Business DaysFord Fusion Inlet Valve

Part Number: 1S7Z-6507-AA$14.30 MSRP: $20.90You Save: $6.60 (32%)Ships in 1-3 Business DaysFord Fusion Inlet Valve

Part Number: 9S4Z-6507-C$14.30 MSRP: $20.90You Save: $6.60 (32%)Ships in 1-3 Business DaysFord Fusion Inlet Valve

Part Number: 1S7Z-6507-B$17.12 MSRP: $24.38You Save: $7.26 (30%)Ships in 1-3 Business DaysFord Fusion Inlet Valve

Part Number: BM5Z-6507-B$17.56 MSRP: $25.67You Save: $8.11 (32%)Ships in 1 Business DayFord Fusion Inlet Valve

Part Number: BM5Z-6507-A$17.56 MSRP: $25.67You Save: $8.11 (32%)Ships in 1 Business DayFord Fusion Inlet Valve

Part Number: F6DZ-6507-A$27.84 MSRP: $40.70You Save: $12.86 (32%)Ships in 1-2 Business Days

Ford Fusion Intake Valve

In the Ford Fusion vehicles, there is the Intake Valve that helps in controlling the air and fuel mixture to result in efficient combustion and thus improving the performance of the engine. The flows of these valves have to open and shut at prescribed periods, and any flaw results in inadequate combustion and loss of energy output. Several Intake Valves have been used in Ford Fusion over the years, but information on certain models is not given clearly. As for the kind of operation, the general idea of the Intake Valve replacement mechanism is the same, here follows a list of steps together with the tools needed that comprises: valve spring remover and compressor. It is important that Ford Fusion Intake Valves should be replaced before it causes much damage to the Fusion's engine and before it results to expensive damages.

We provide a wide range of Ford Fusion Intake Valve at the best prices possible. If you need Ford Fusion Intake Valve, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Fusion Intake Valve Parts Questions & Experts Answers

- Q: How to check and adjust valve clearances on Ford Fusion?A:First, pull the battery cable away from the negative terminal; remove all of the spark plugs and the valve cover. Some of the challenges are Loosen the right front wheel lug nuts-lift the front of the vehicle-support the vehicle secured on jack stands-remove the right front wheel and the fender splash shield. On another engine, with a wrench or socket on the crankshaft pulley bolt, turn the crankshaft clockwise and check each lifter when its Camshaft lobe is directly vertical, it's preferred that the distance is between cam base circle and top of the lifter. The correct clearances are obtained by the use of feeler gauges with a very slight drag being felt when sliding the gauge between the lifter and camshaft. A measurement check should be carried between the clearance of each of the camshaft lobe with the appropriate lifter and document all the readings. In the event that any of the anterior mentioned clearances prove to be out of standard, both the camshafts and lifters that are out of spec must be withdrawn. New lifters are available in various thicknesses, it is stamped with a thickness number; only the numbers after the decimal point are important. To decide the lifters' thickness for a new set, sum together the thickness of an original lifter and the measured clearance, and then subtract the midrange figure for the ideal clearance to arrive at the proper thickness of the lifter to order, choosing the closest available thickness. After the camshafts and Timing Chain have been fitted, it is essential to again inspect the valve clearances; after that, the work is done in reverse order. Last but not least of the oil change procedures is to start the engine and inspect it for oil loss.