My Garage

My Account

Cart

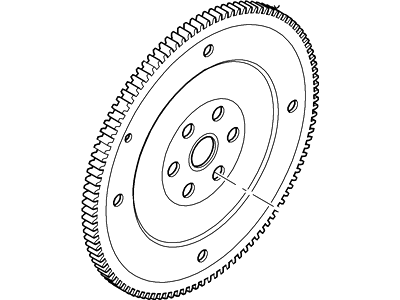

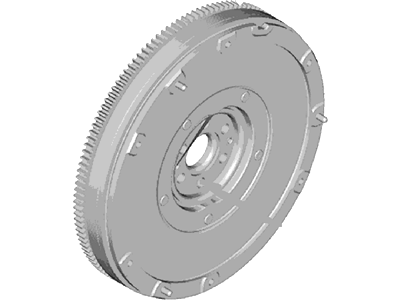

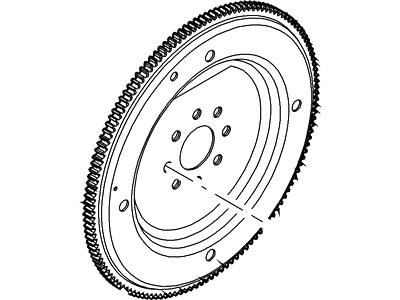

Genuine Ford Fusion Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Flywheels found

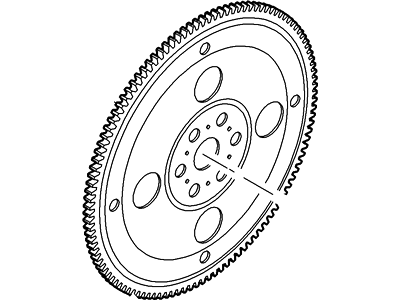

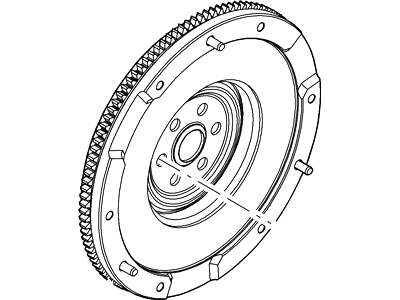

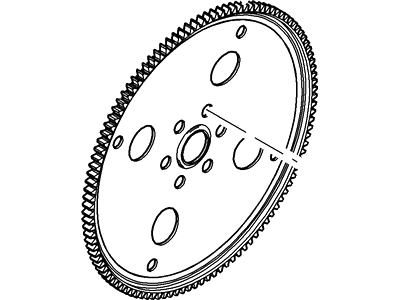

Ford Fusion Flywheel Assembly

Part Number: 1S7Z-6375-C$75.81 MSRP: $110.83You Save: $35.02 (32%)Ships in 1-3 Business DaysFord Fusion Flywheel Assembly

Part Number: CV6Z-6375-C$84.14 MSRP: $123.02You Save: $38.88 (32%)Ships in 1-3 Business DaysFord Fusion Flywheel Assembly

Part Number: 1S7Z-6375-B$75.81 MSRP: $110.83You Save: $35.02 (32%)Ships in 1 Business DayFord Fusion Flywheel Assembly

Part Number: 1L8Z-6375-AA$75.81 MSRP: $110.83You Save: $35.02 (32%)Ships in 1 Business DayFord Fusion Flywheel And Ring Gear Assembly

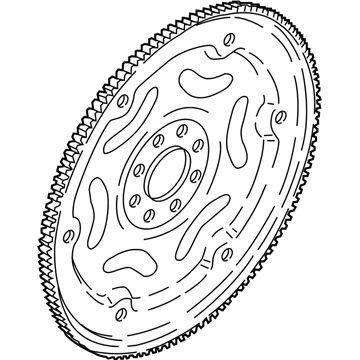

Part Number: 5M6Z-6375-AA$96.59 MSRP: $134.18You Save: $37.59 (29%)Ships in 1-2 Business DaysFord Fusion Flywheel And Ring Gear Assembly

Part Number: DG9Z-6375-B$218.77 MSRP: $322.67You Save: $103.90 (33%)Ships in 1-3 Business DaysFord Fusion Flywheel And Ring Gear Assembly

Part Number: DG9Z-6375-A$218.77 MSRP: $322.67You Save: $103.90 (33%)Ships in 1-3 Business DaysFord Fusion FLYWHEEL ASY

Part Number: CV6Z-6375-E$84.14 MSRP: $123.02You Save: $38.88 (32%)Ships in 1-2 Business DaysFord Fusion FLYWHEEL ASY

Part Number: 1S7Z-6375-D$75.81 MSRP: $110.83You Save: $35.02 (32%)Ships in 1 Business DayFord Fusion Flywheel Assembly

Part Number: FG9Z-6375-A$62.32 MSRP: $91.12You Save: $28.80 (32%)Ships in 1-3 Business Days

Ford Fusion Flywheel

We provide a wide range of Ford Fusion Flywheel at the best prices possible. If you need Ford Fusion Flywheel, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Fusion Flywheel Parts Questions & Experts Answers

- Q: How to remove, inspect, and install the flywheel on Ford Fusion?A:To remove the transaxle, first check components like oil seals and replace them if necessary. For manual transaxle models, remove the clutch and inspect or replace the clutch components and release bearing. Make alignment marks on the flywheel and crankshaft to simplify replacement, as the bolt holes are slightly offset. Hold the flywheel/driveplate stationary while unscrewing the bolts; use a transaxle mounting bolt and a wide-bladed screwdriver to prevent turning. Remove each bolt in turn, ensuring new replacements are obtained for reassembly due to the severe stresses they endure. Carefully remove the heavy flywheel, noting that the driveplate for automatic transaxles is lighter. Clean the flywheel to eliminate grease and oil, inspecting for cracks, rivet grooves, burned areas, and score marks, with light scoring removable using emery cloth. Check for cracked and broken ring gear teeth and verify warpage with a straight-edge. Clean the mating surfaces of the flywheel and crankshaft, replacing the oil seal if leaking, especially in high-mileage engines. While the flywheel is off, clean its inboard face and the crankshaft speed/position sensor. For installation, ensure the engine/transaxle adapter plate is in place, align the flywheel/driveplate on the crankshaft using the marks made during removal, and install new bolts, tightening them by hand. Lock the flywheel using the disassembly method, tightening the bolts in a diagonal sequence and gradually increasing to the final torque in two or three stages. The remainder of reassembly follows the reverse of the removal process.